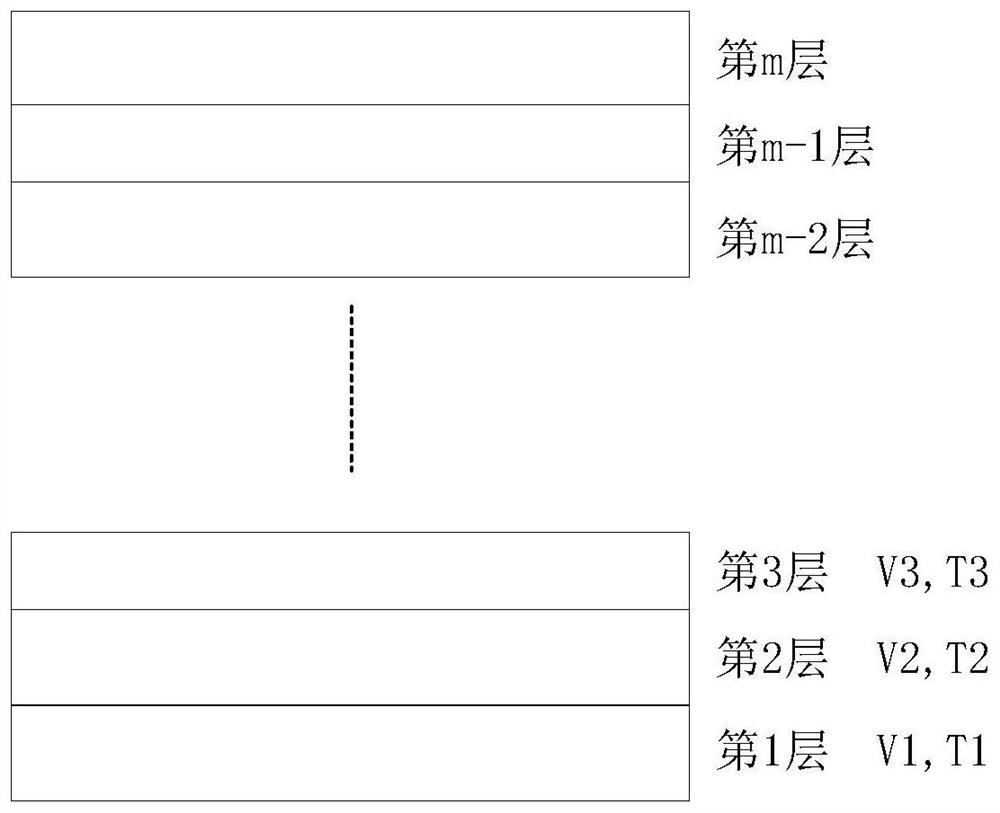

Method for regulating and controlling microstructure of directional energy additive manufacturing titanium alloy part

A technology of additive manufacturing and microstructure, applied in additive manufacturing, additive processing, etc., can solve the problems of increased difficulty in temperature gradient control, difficulty in obtaining titanium alloy products, and increased difficulty in tissue control, achieving good application prospects and avoiding holes Defect issues, effects of avoiding multiple trials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

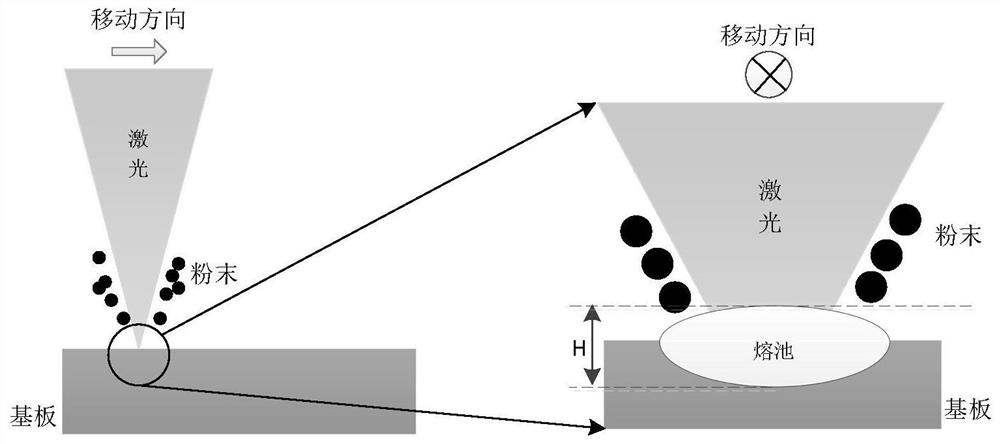

Method used

Image

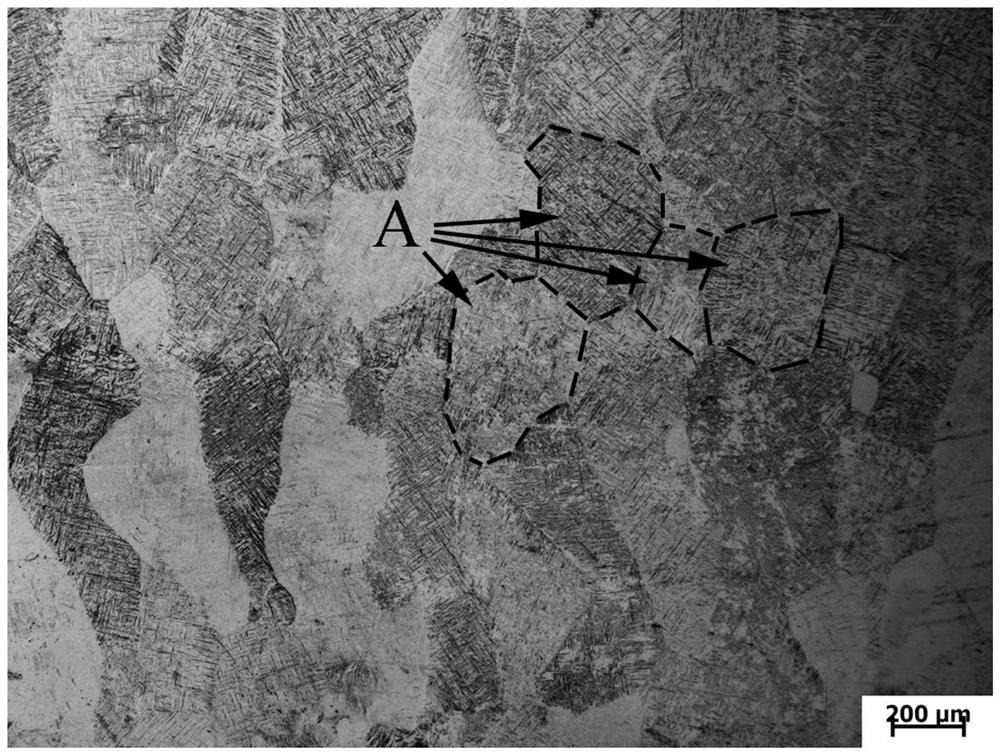

Examples

Embodiment 1

[0122] Step 1: Prepare a TC4 substrate with a thickness of 15mm and a TC4 spherical powder with a specification of 75-180μm.

[0123] Step 2: Position the TC4 substrate and the laser head, seal the device, and fill it with argon gas with a purity of 99.999% to reduce the oxygen content inside the device to below 200ppm.

[0124] Step 3: Set the scanning speed to 600mm / min, the initial powder feeding speed to 4.5g / min, and the laser power to 1200W, and conduct a single-channel test. The measured width of the melting channel is about 2.8mm, and the height of the melting channel is about 0.7mm. Among them, the cladding layer The height is about 0.4mm.

[0125] Step 4: Repeat steps 1 and 2 to prepare equipment and TC4 powder.

[0126] Step 5: Set the laser power to 1200W, the laser scanning spacing to 600mm / min, the laser scanning spacing to 1.6mm (the lateral overlap rate is 43%), the scanning strategy is reciprocating, and 90° rotation between layers, through The actual claddi...

Embodiment 2

[0129] Step 1: Prepare a TC4 substrate with a thickness of 15mm and a TC4 spherical powder with a specification of 75-180μm.

[0130] Step 2: Position the TC4 substrate and the laser head, seal the device, and fill it with argon gas with a purity of 99.999% to reduce the oxygen content inside the device to below 200ppm.

[0131] Step 3: Set the scanning speed to 600mm / min, the initial powder feeding speed to 4.5g / min, and the laser power to 1200W, and conduct a single-channel test. The measured width of the melting channel is about 2.8mm, and the height of the melting channel is about 0.7mm. Among them, the cladding layer The height is about 0.4mm.

[0132] Step 4: Repeat steps 1 and 2 to prepare equipment and raw materials.

[0133]Step 5: Set the laser power to 1200W, the laser scanning spacing to 600mm / min, the laser scanning spacing to 1.68mm (the lateral overlap rate is 40%), the scanning strategy is reciprocating, and the interlayer 90 ° rotation, through The actual cl...

Embodiment 3

[0136] Step 1: Prepare a TC4 substrate with a thickness of 15mm and a TC4 spherical powder with a specification of 75-180μm.

[0137] Step 2: Position the TC4 substrate and the laser head, seal the device, and fill it with argon gas with a purity of 99.999% to reduce the oxygen content inside the device to below 200ppm.

[0138] Step 3: Set the scanning speed to 600mm / min, the initial powder feeding speed to 4.5g / min, and the laser power to 1200W, and conduct a single-channel test. The measured width of the melting channel is about 2.8mm, and the height of the melting channel is about 0.7mm. Among them, the cladding layer The height is about 0.4mm.

[0139] Step 4: Repeat steps 1 and 2 to prepare equipment and raw materials.

[0140] Step 5: Set the laser power to 1200W, the laser scanning spacing to 600mm / min, the laser scanning spacing to 1.68mm (the lateral overlap rate is 40%), the scanning strategy is reciprocating, and the interlayer 90 ° rotation, through The actual c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com