Comprehensive Utilization Method of Titanium White Waste Acid Wastewater

A technology of titanium white waste acid and waste water, which is applied in the direction of titanium compounds, chemical instruments and methods, rare earth metal compounds, etc., can solve the problem of not being able to make full use of titanium white waste acid waste water at low cost, and achieve significant economic and social benefits, Good promotion prospects and the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

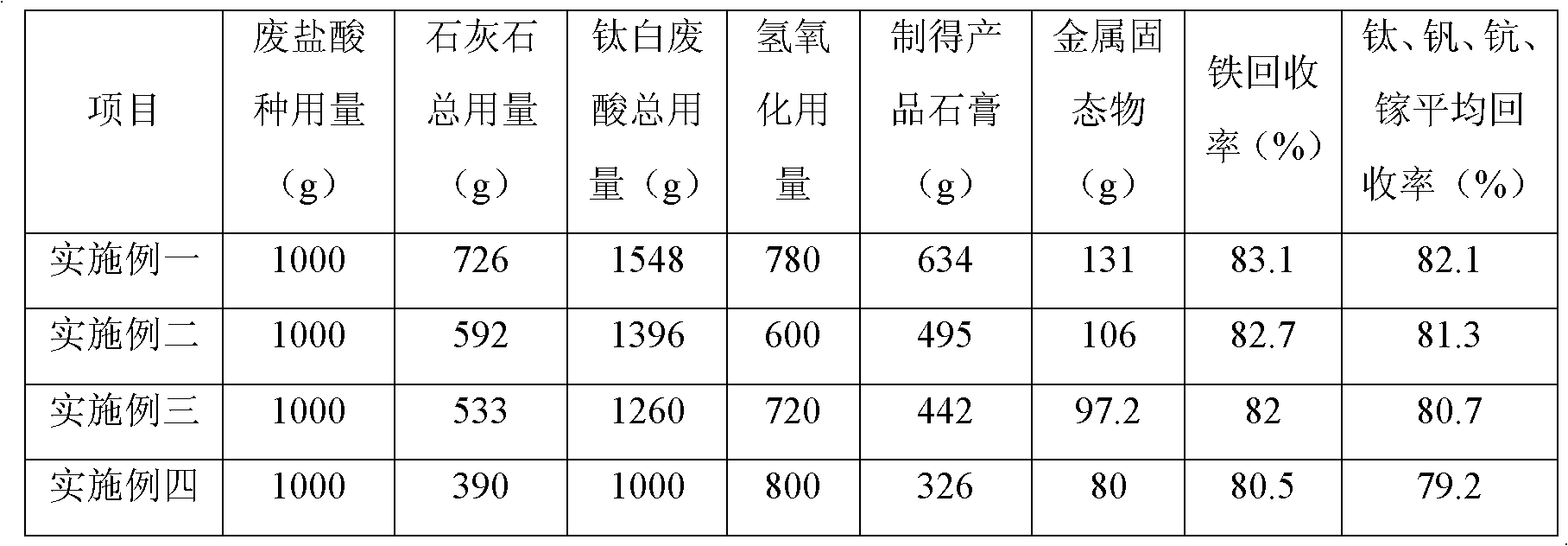

Embodiment 1

[0042] Embodiment 1 Treatment of titanium white waste acid with the method of the present invention

[0043] Raw material used in this embodiment: hydrochloric acid solution: mass fraction is 25% industrial waste hydrochloric acid, also contains free chlorine 18ppm, Ca 2+ : 20.8ppm, Mg 2+ : 12.25ppm, Fe 2+ : 2.3%, from Panzhihua Steel Enterprise Xinyu Chemical Co., Ltd. Limestone: The mass percentage of calcium carbonate is 90%, and it also contains trace amounts of silicon dioxide, aluminum oxide, ferric oxide and magnesium oxide, and is sourced from Panzhihua Xingzhong Titanium Industry Co., Ltd. Titanium white waste acid: sulfuric acid 21.12%, iron 5.4%, titanium 0.98%, vanadium 440g / t, scandium 26g / t, gallium 22g / t, sourced from Panzhihua Tianlun Chemical Co., Ltd. Commercially available 30% sodium hydroxide.

[0044] a, prepare calcium chloride solution: add limestone 388g in 1000g industrial waste hydrochloric acid, filter after fully reacting, collect filtrate, reco...

Embodiment 2

[0051] Embodiment two processing titanium white waste acid with the method of the present invention

[0052] Raw material used in this embodiment: hydrochloric acid solution: mass fraction is 16% industrial waste hydrochloric acid, also contains free chlorine 13ppm, Ca 2+ : 14.8ppm, Mg 2+ : 7.3ppm, Fe 2+ : 1.6%, from Panzhihua Steel Enterprise Xinyu Chemical Co., Ltd. Limestone: The mass percentage of calcium carbonate is 93.1%, and it also contains trace amounts of silicon dioxide, aluminum oxide, iron oxide and magnesium oxide, and is sourced from Panzhihua Xingzhong Titanium Industry Co., Ltd. Titanium white waste acid: 20.5% sulfuric acid, 5.1% iron, 0.95% titanium, 410g / t vanadium, 25g / t scandium, 21g / t gallium, sourced from Panzhihua Tianlun Chemical Co., Ltd. Commercially available 30% sodium hydroxide.

[0053] a, prepare calcium chloride solution: add limestone 275g excessively 15% in 1000g industrial waste hydrochloric acid, filter after fully reacting, collect f...

Embodiment 3

[0062] Embodiment three processing titanium white waste acid with the method of the present invention

[0063] Raw materials used in this embodiment (with embodiment two): hydrochloric acid solution: mass fraction is 16% industrial waste hydrochloric acid, also contains free chlorine 13ppm, Ca 2+ : 14.8ppm, Mg 2+ : 7.3ppm, Fe 2+ : 1.6%, from Panzhihua Steel Enterprise Xinyu Chemical Co., Ltd. Limestone: The mass percentage of calcium carbonate is 93.1%, and it also contains trace amounts of silicon dioxide, aluminum oxide, iron oxide and magnesium oxide, and is sourced from Panzhihua Xingzhong Titanium Industry Co., Ltd. Titanium white waste acid: 20.5% sulfuric acid, 5.1% iron, 0.95% titanium, 410g / t vanadium, 25g / t scandium, 21g / t gallium, sourced from Panzhihua Tianlun Chemical Co., Ltd. Commercially available 30% sodium hydroxide.

[0064] a, prepare calcium chloride solution: add limestone 275g excessively 15% in 1000g industrial waste hydrochloric acid, filter after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com