Undermount drawer slide

a drawer slide and drawer body technology, applied in drawers, furniture parts, domestic applications, etc., can solve the problems of not being easily assembled beforehand, noise, binding, durability, etc., and achieve the effect of reducing the amount of material and reducing the noise and impact for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

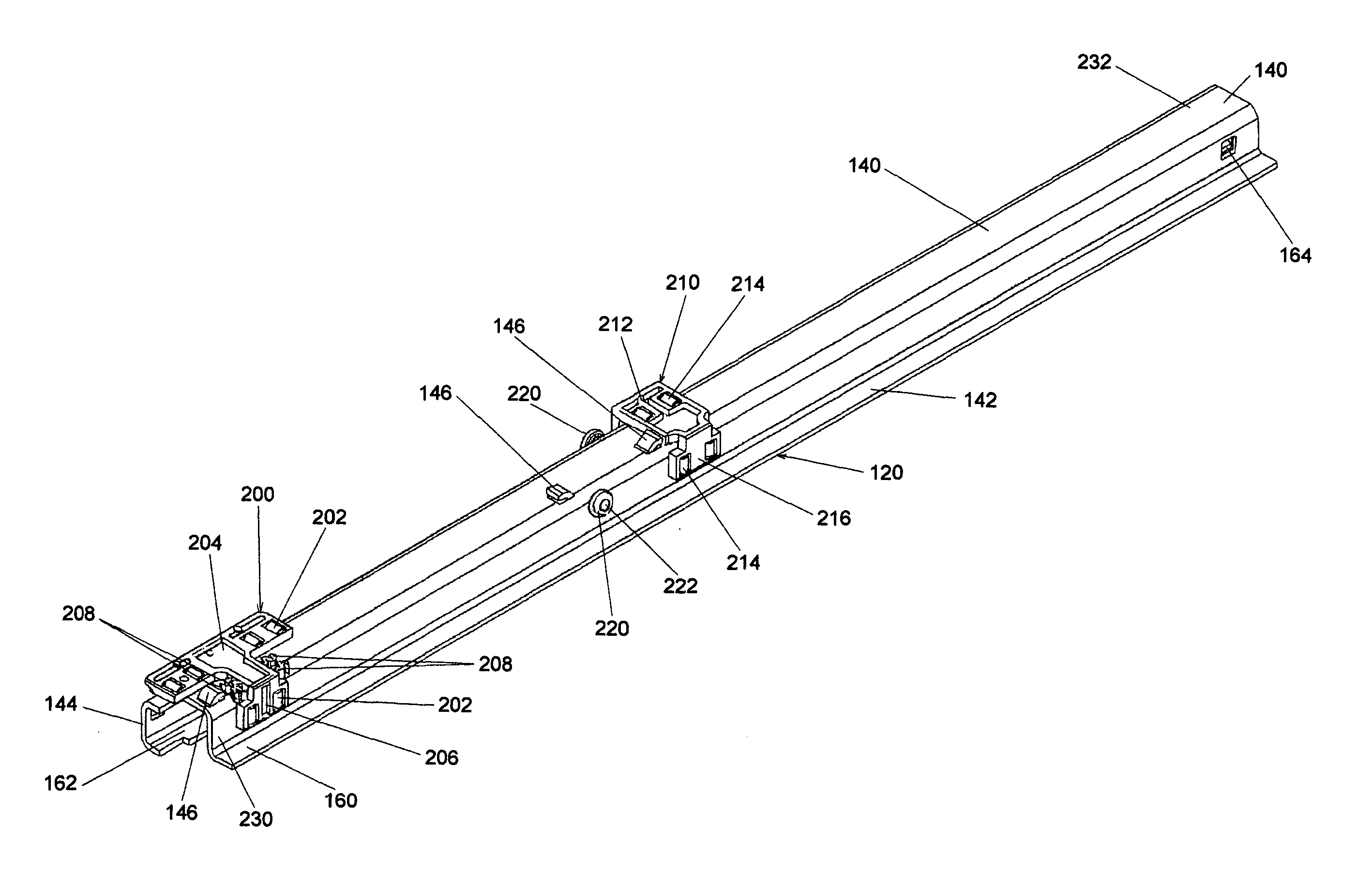

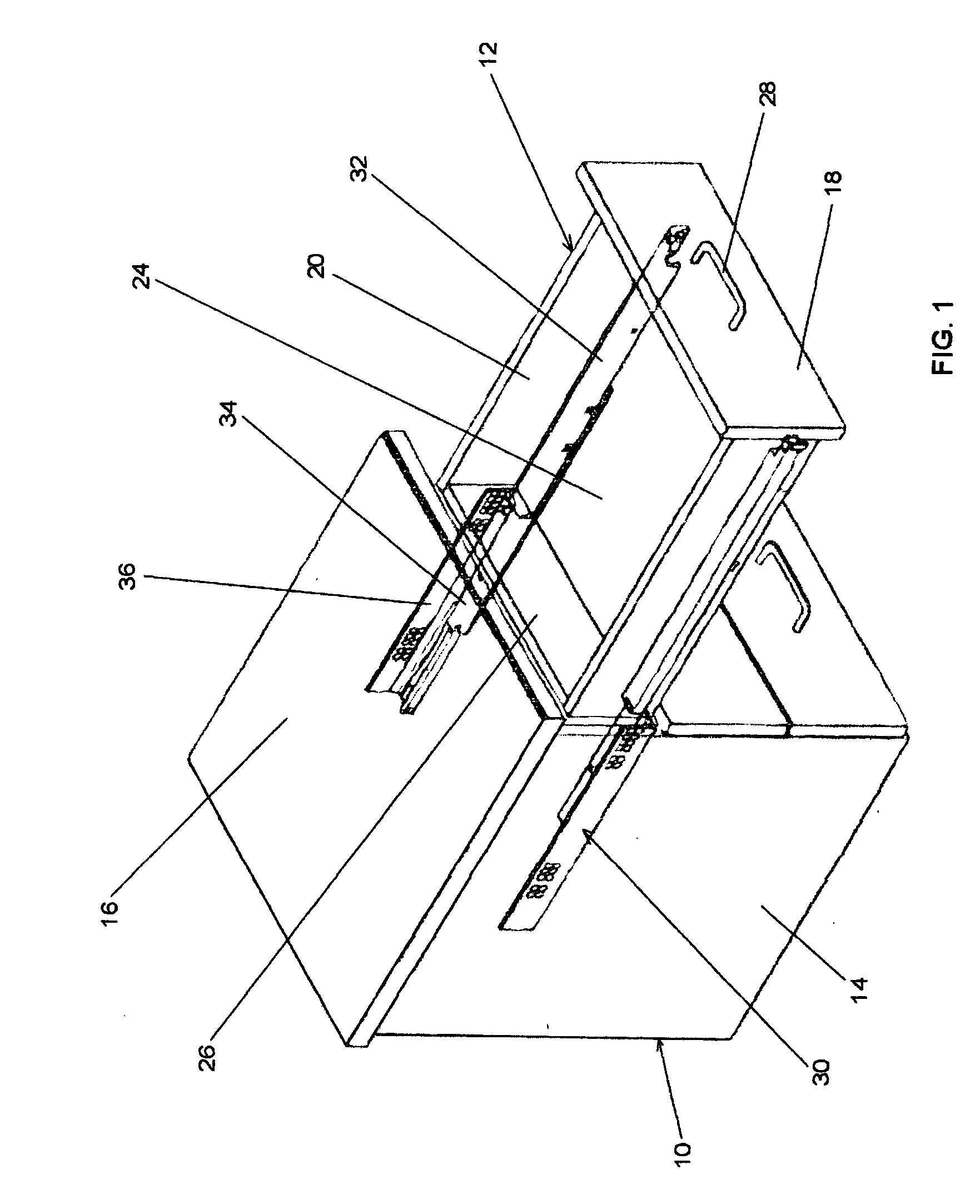

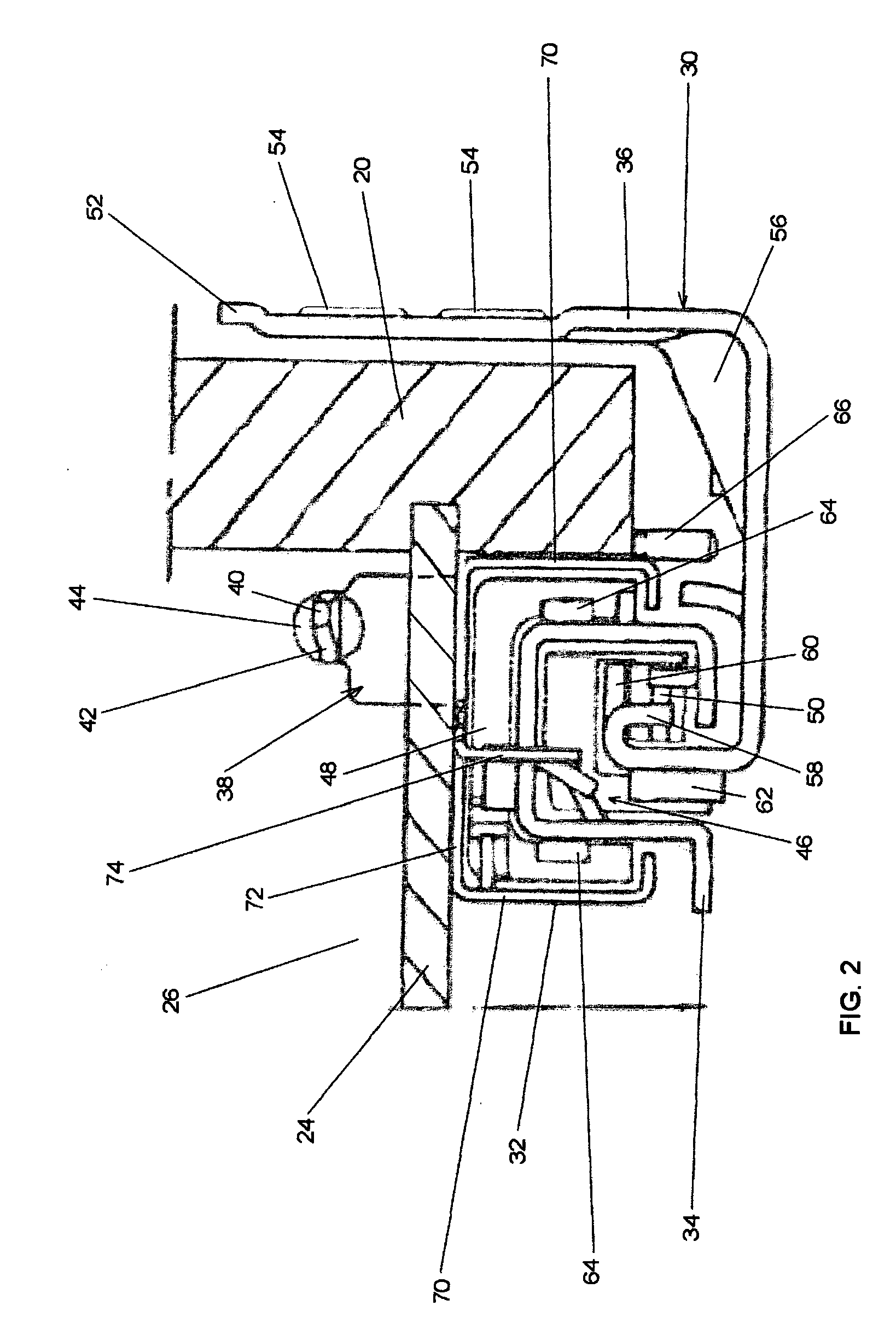

[0048] A novel undermount drawer slide of the present invention is premised upon the telescoping members typically associated with drawer slides of this type as shown in FIG. 1 and as discussed above. This arrangement is shown with more detail in FIG. 2 where the elements of the subject drawer slide and its relationship to a drawer are illustrated.

[0049] Specifically, the undermount drawer slide 30 is comprised of the drawer member 32, the intermediated member 34 and the cabinet member 36. Shown hidden behind the drawer back 26 is the drawer member tab 38 with drawer member tab point 40 with tapered point sides 42. The drawer member tab point and a substantial portion of the drawer member tab projects through the drawer back mounting hole 44 which is shown in its mounted position. The drawer back wall 26 is indicated as being coextensive from the drawer side 20 to the drawer bottom 24 and ultimately to the opposing drawer side (not shown). The typical drawer construction is indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com