Construction site flat plate die dismantling equipment

A technology for construction sites and slabs, which is used in construction, on-site preparation of building components, building construction, etc., can solve the problems of falling slab moulds on the ground, affecting the safety of workers, and low demolition efficiency, and achieves convenient The effect of handling, ensuring cleanliness and safety, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

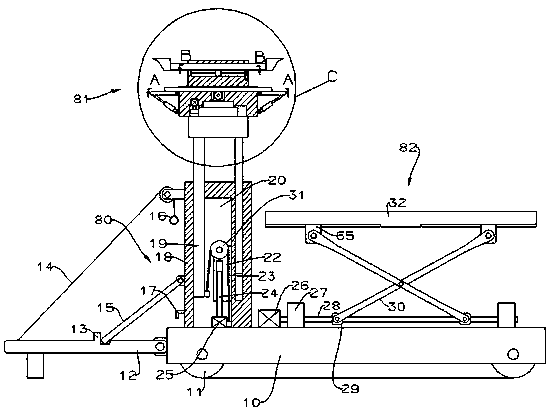

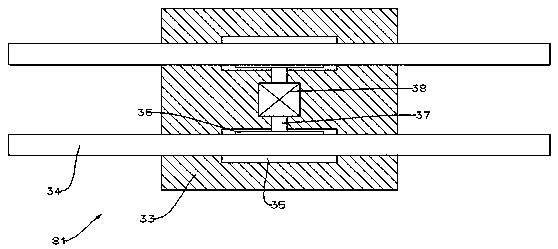

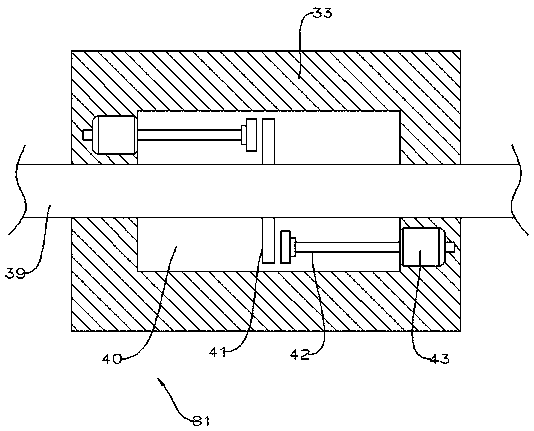

[0021] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

[0022] refer to Figure 1-5 According to an embodiment of the present invention, a construction site plate formwork removal device includes a base 10, a fixing seat 18 is fixedly installed on the top surface of the base 10, and a telescopic space 20 is provided inside the fixing seat 18, and the telescopic Slide bar 19 is slidably installed on the top surface of space 20 and described base 10, and described flexible space 20 is provided with can drive describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com