Agricultural straw smashing device

A technology of straw crushing and crushing rollers, which is applied in the field of agricultural machinery, can solve the problems of reduced straw crushing efficiency, environmental pollution, and corrosion of the inner wall of the device body, and achieves the convenience and speed of adding lubricating oil, ensuring personal safety, and safe and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

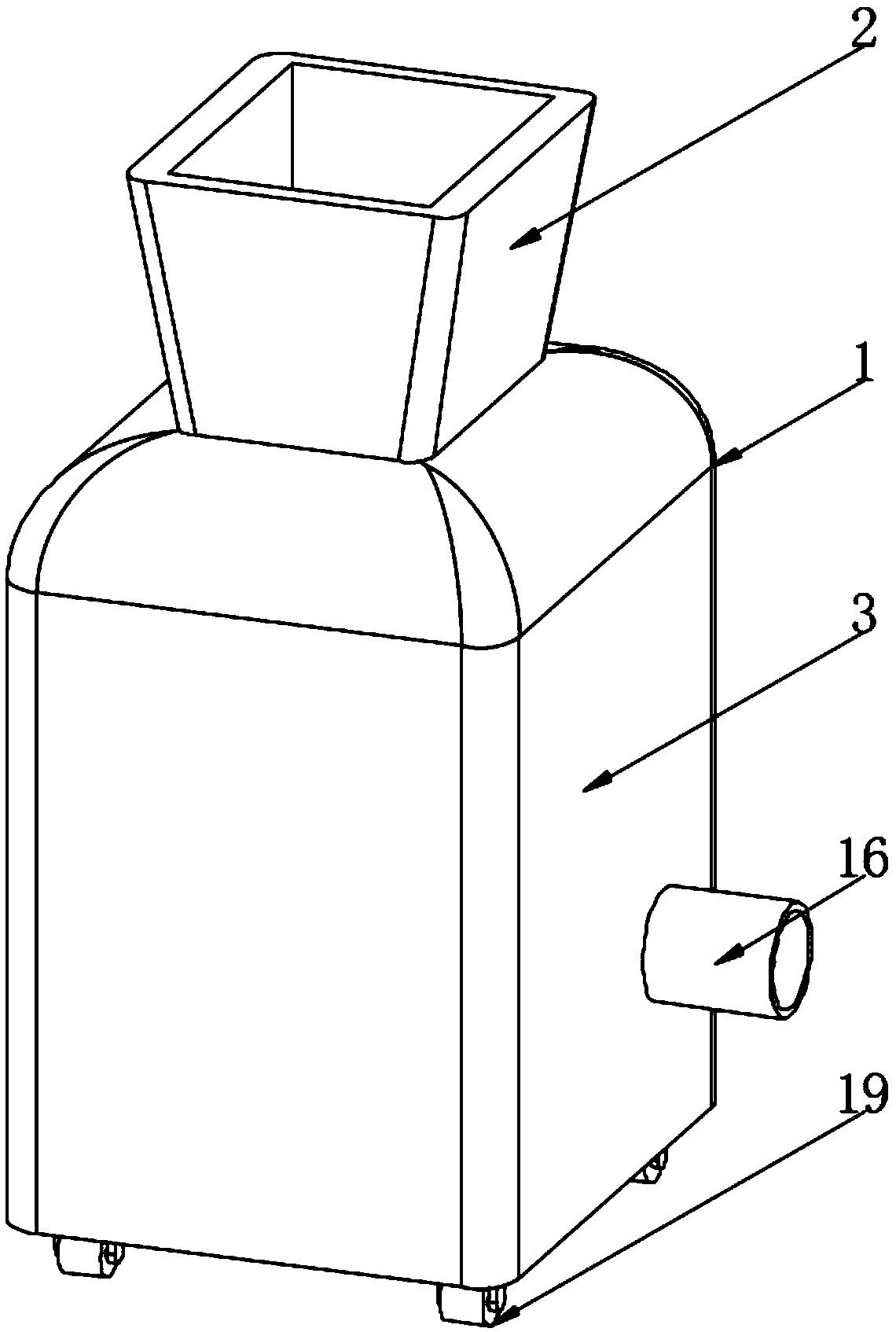

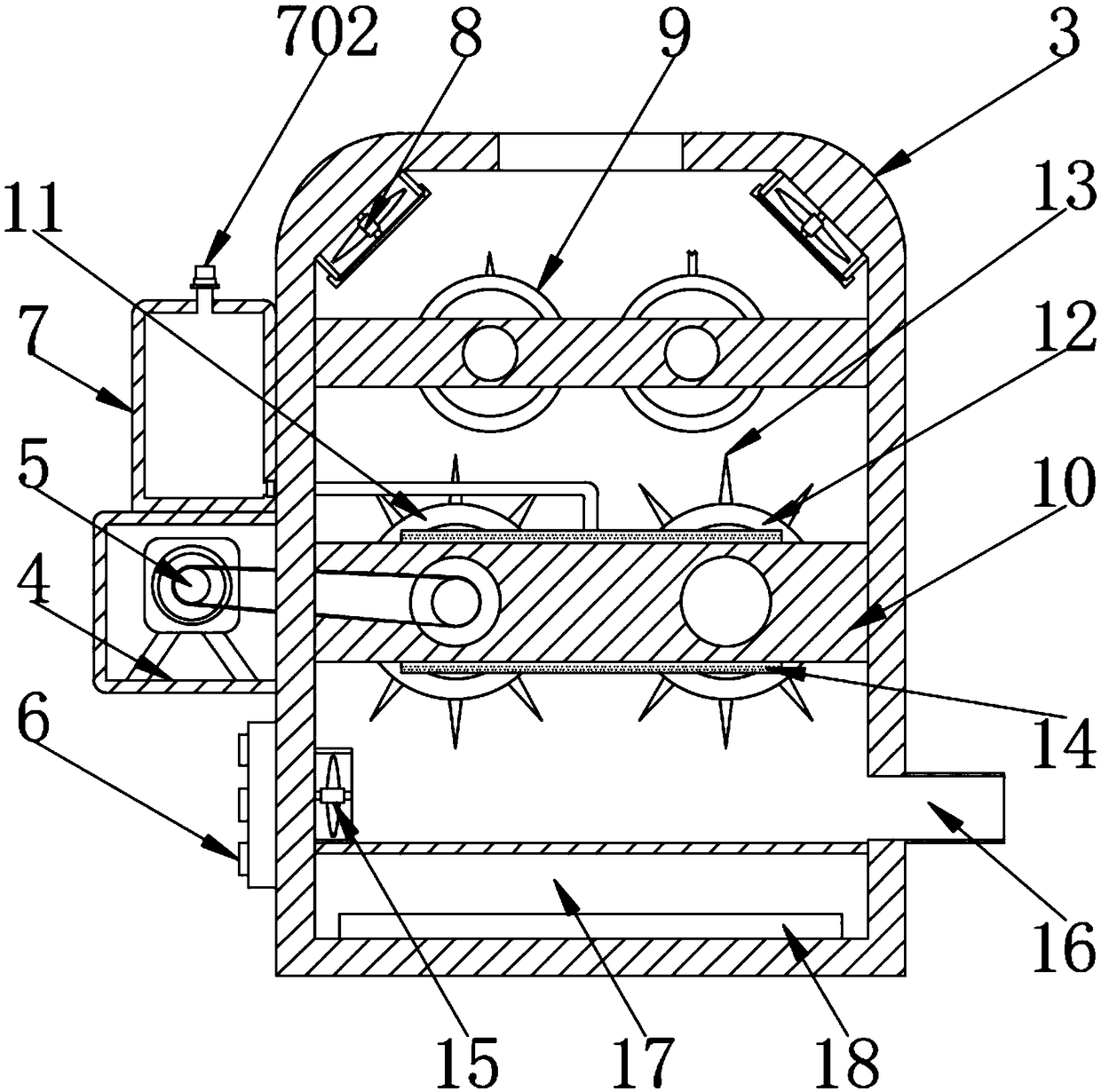

[0035] Example: such as Figure 1-8As shown, the present invention provides a technical solution, an agricultural straw crushing device, including a device body 1, and a feeding assembly 2 is arranged at the top of the device body 1;

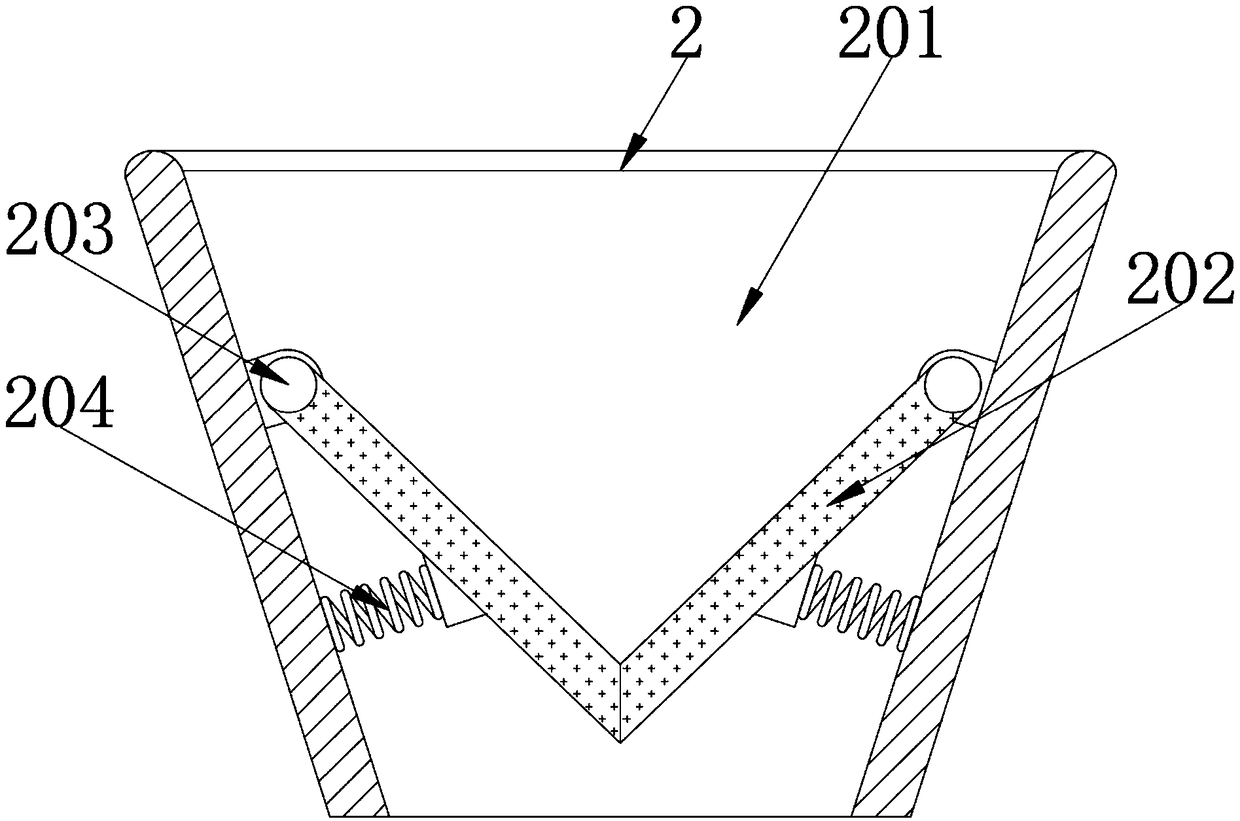

[0036] The feed assembly 2 includes a feed port 201, a baffle plate 202, a rotating shaft 203 and a return spring 204. The feed assembly 2 is provided with a feed port 201, and the inner side wall of the feed port 201 is rotated by a rotating shaft 203. A baffle plate 202 is installed. In order to prevent the shielding plate 202 from being severely worn due to long-term use, a wear-resistant rubber pad is pasted on the upper surface of the shielding plate 202, and a return spring 204 is fixedly installed between the shielding plate 202 and the side wall of the feed port 201 through a spring holder.

[0037] The crushing box 3 is installed under the feeding assembly 2, and the middle part of one side of the crushing box 3 is welded with the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com