Material crushing machine

The technology of a shredder and a casing is applied in the field of plastic processing equipment, which can solve the problems such as the difficulty in guaranteeing the size of shredded fragments and the large difference in size, and achieve the effect of improving the large difference in size, uniform size and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

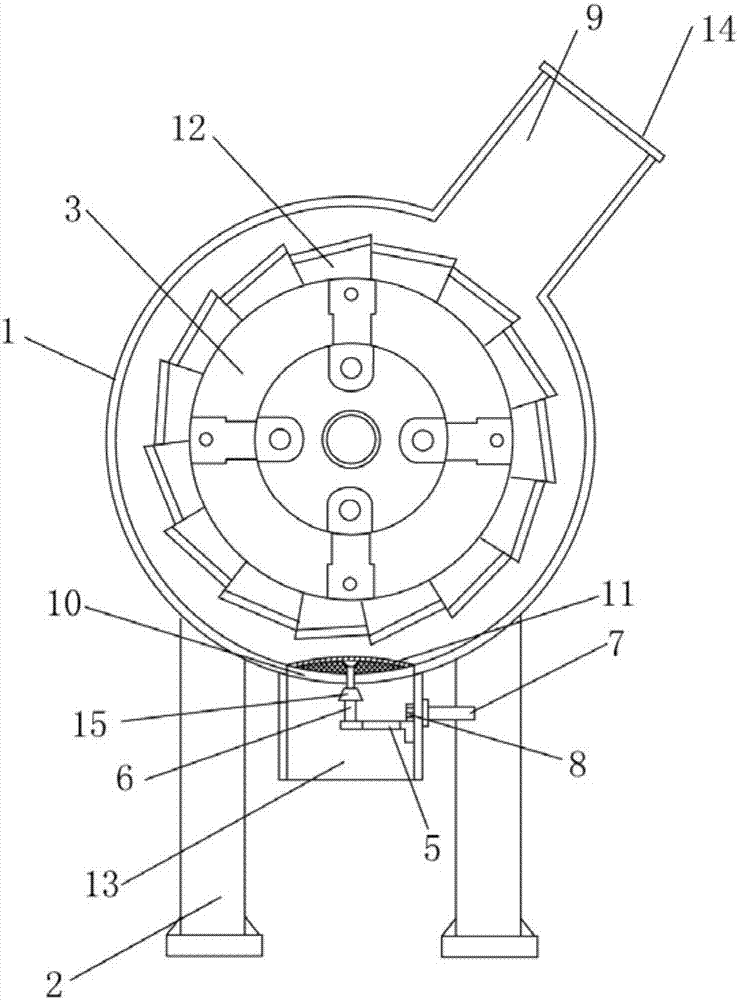

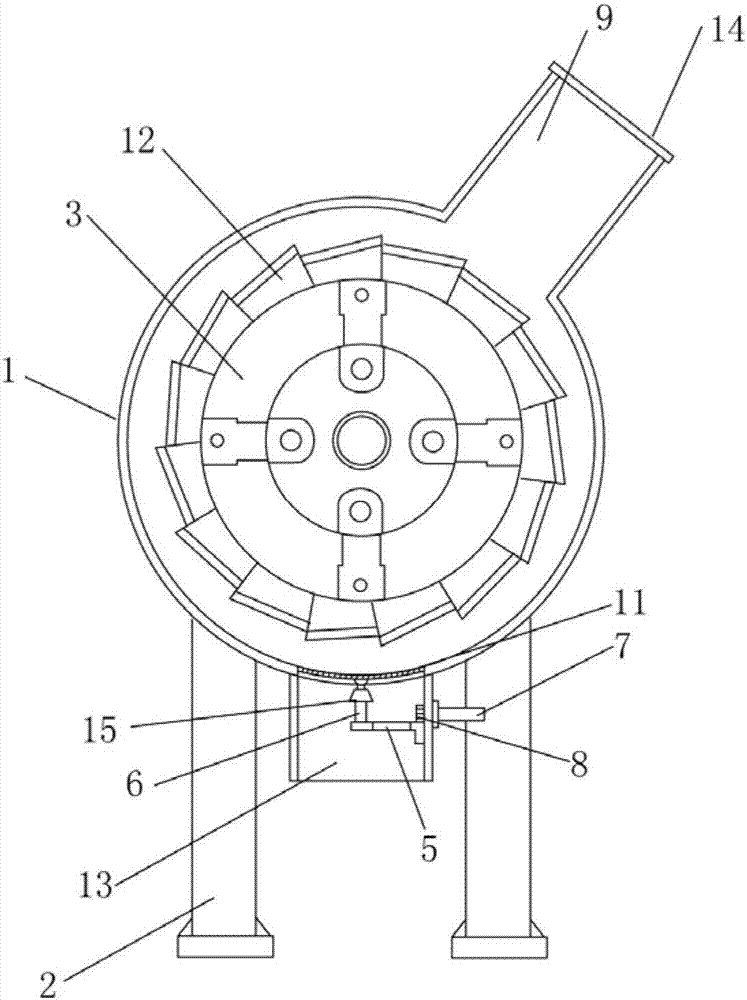

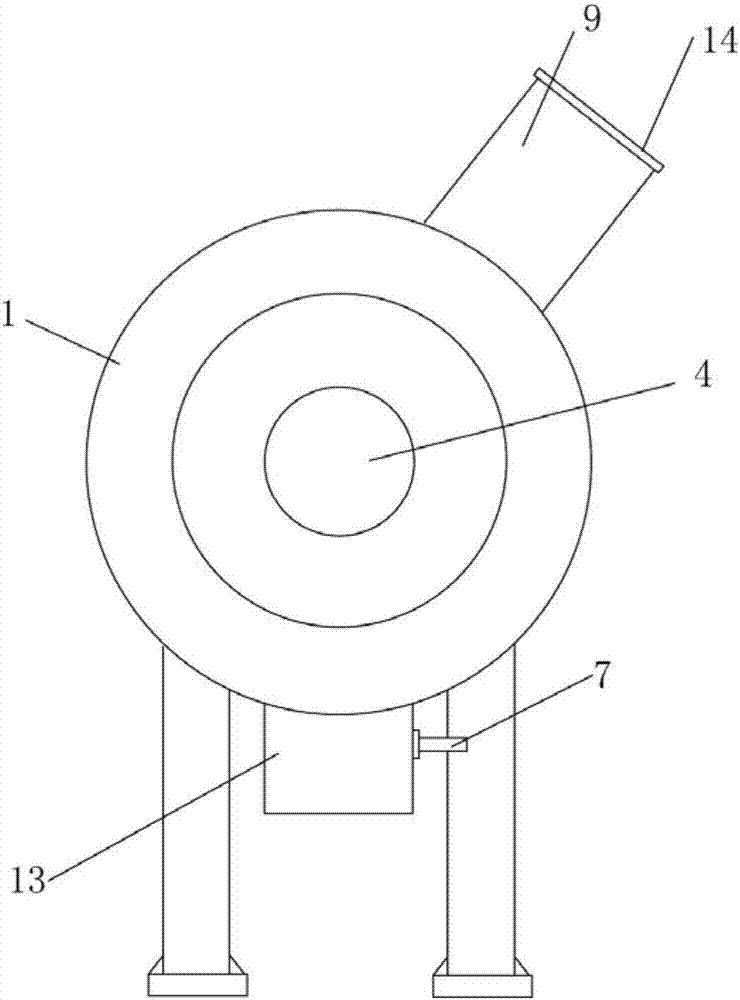

[0023] like Figure 1-3 As shown, a crushing machine includes a casing 1, a bracket 2, a turntable 3, a motor 4, a fixed plate 5, a first cylinder 6, a second cylinder 7, and a brush 8, and the bracket 2 is welded to the lower part of the casing 1 , the top of the casing 1 is provided with a feed port 9, the bottom of the casing 1 is provided with a discharge port 10, the discharge port 10 is fixed with a screen 11 larger than the discharge port 10, and the turntable 3 is arranged on the casing 1 Inside, the motor 4 is fixed on the outside of the casing 1 and its output shaft is connected with the central axis of the turntable 3, and the outer periphery of the turntable 3 is fixed with a crushing cutter 12; the outside of the discharge port 10 is welded with a discharge mask 13, a fixed plate 5 One end of the first cylinder is welded on the discharge mask 13, the lower end of the first cylinder 6 is fixed on the other end of the fixed plate 5 and its upper end is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com