Ceiling-mounted range hood

A technology for range hood and range hood, which is applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of easy accumulation of oil stains on the filter screen, large negative pressure loss, inconvenient cleaning, etc., so as to maintain the overall appearance and enhance the The effect of smoking, the effect of shortening the distance from the smoke source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

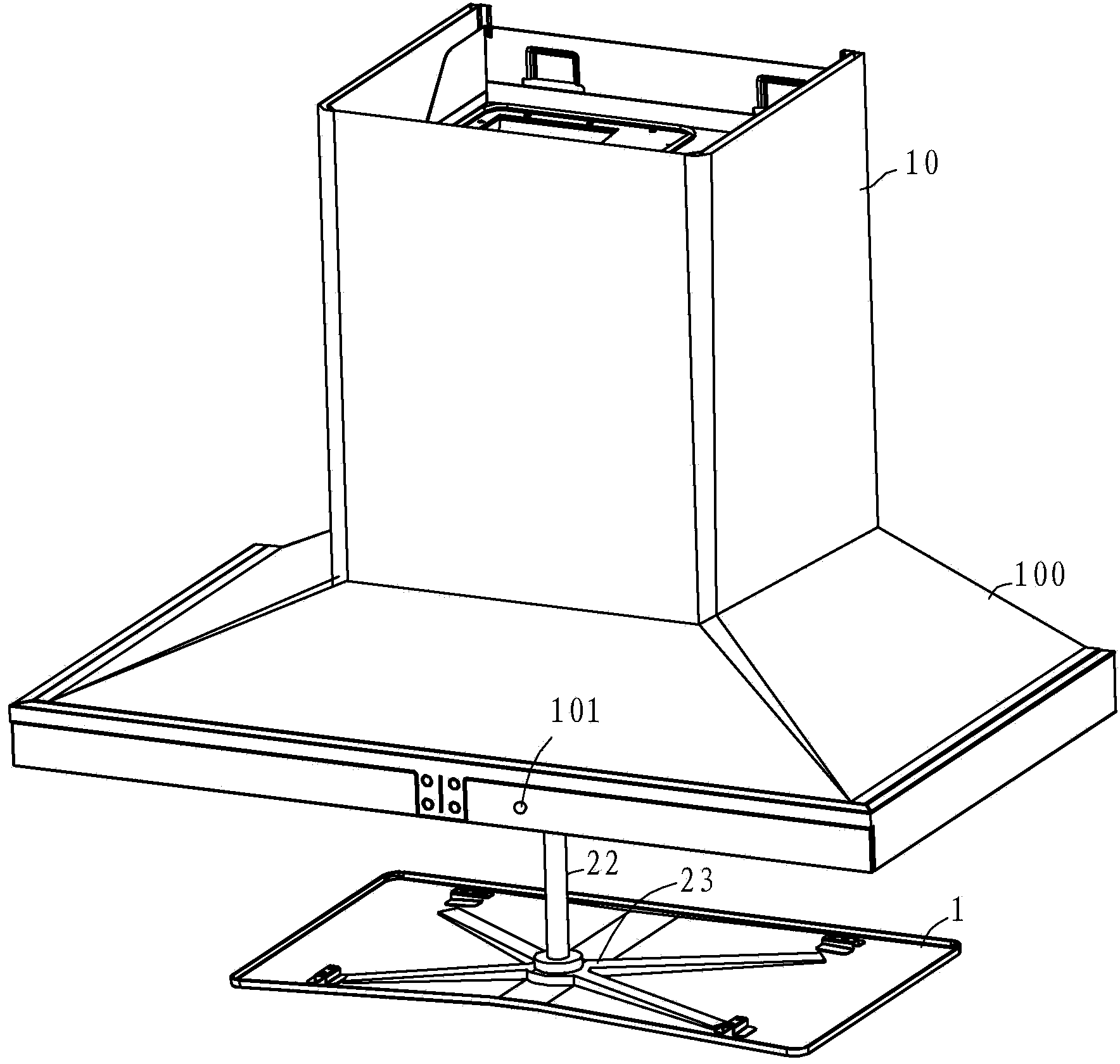

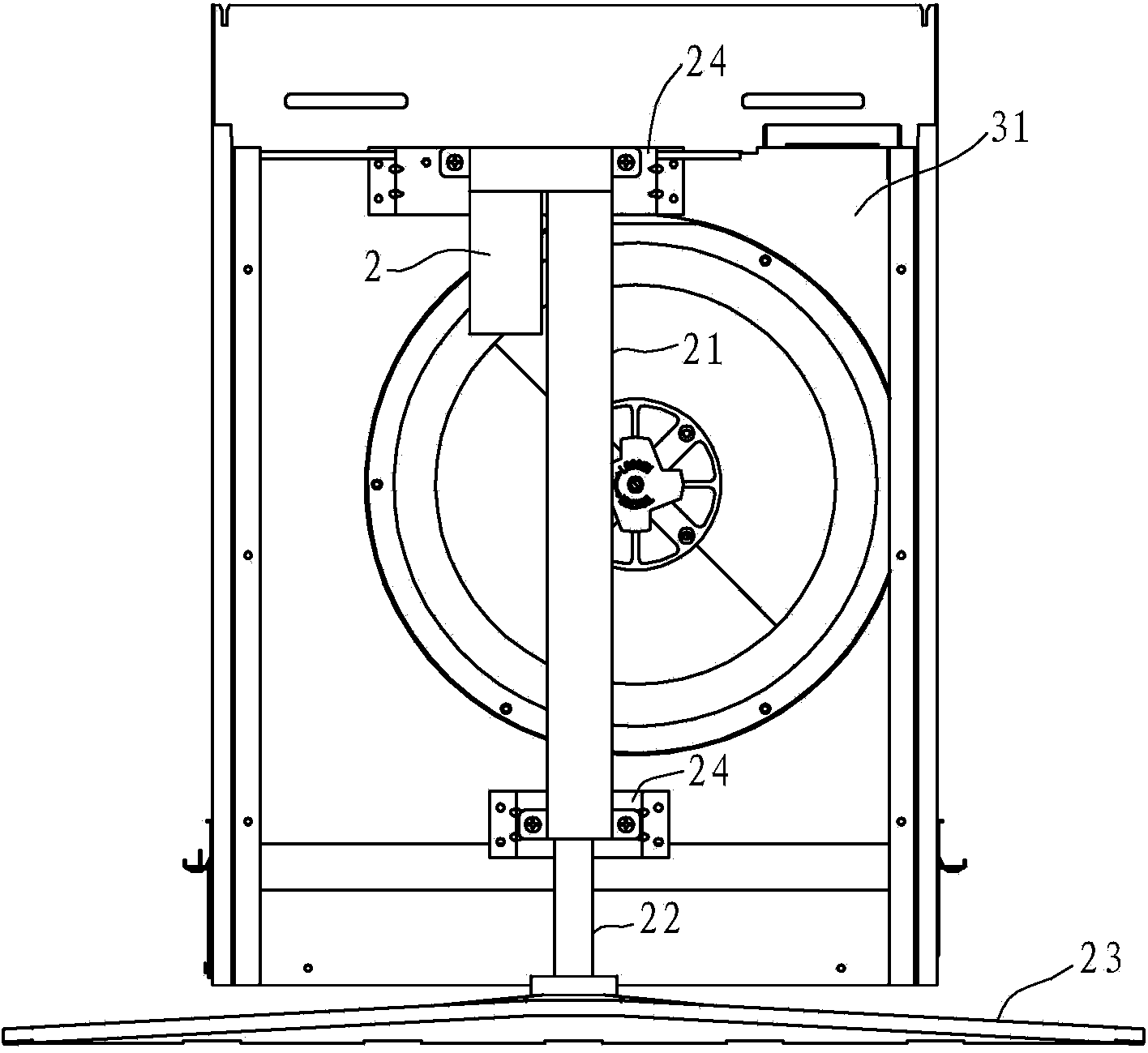

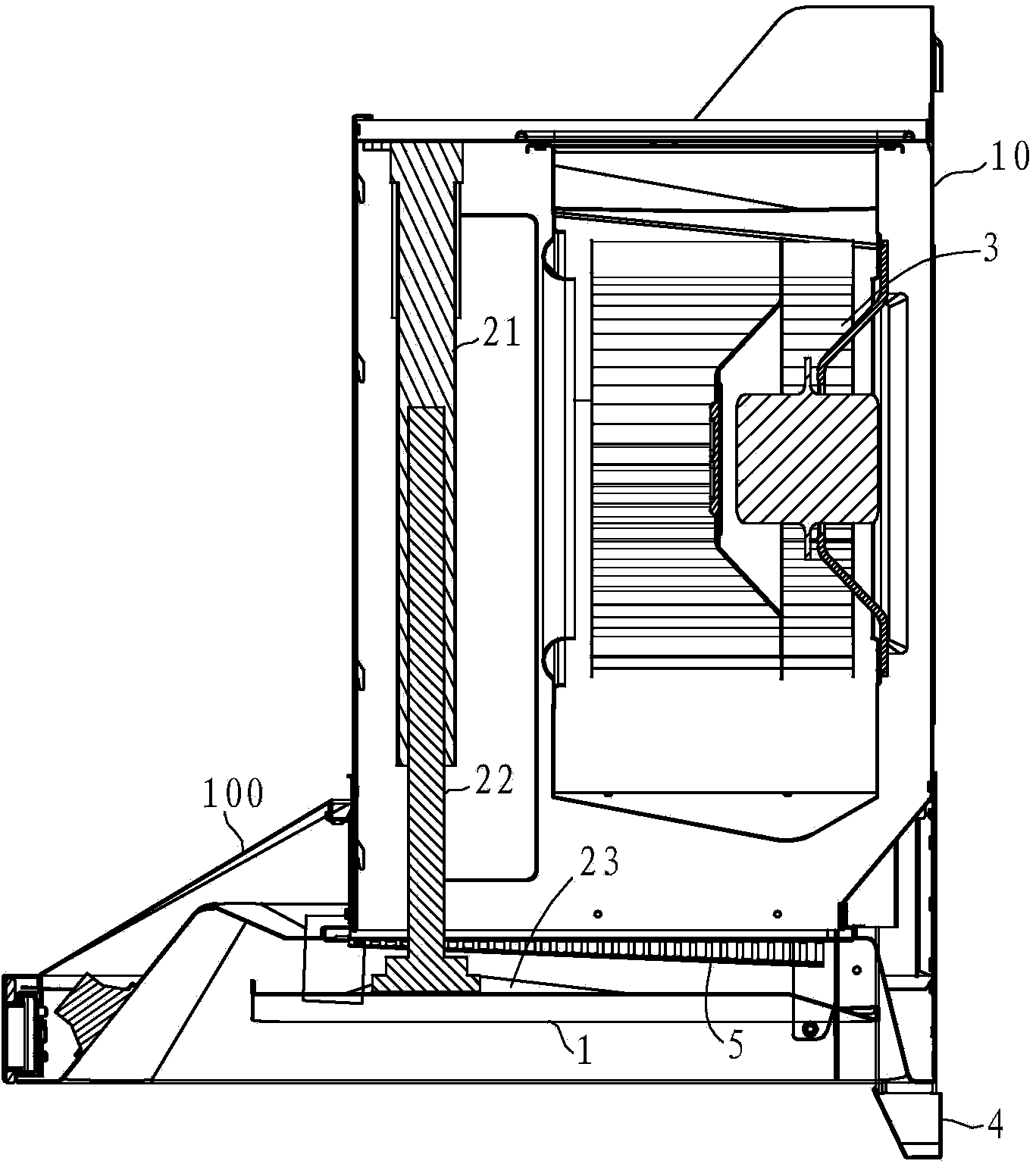

[0042] Example 1, such as Figure 1 to Figure 5 As shown, the top suction range hood in this embodiment includes a body 10, a smoke collecting hood 100, a fan 3 and a rectifying plate 1. The smoke collecting hood 100 has an air inlet from bottom to top, and the rectifying plate 1 is facing the air inlet. The tuyere is set and forms an air inlet channel for oil fumes to pass between the inner cavity wall of the smoke collecting hood 100. The aforementioned machine body 10 is longitudinally arranged on the top of the smoke collecting hood 100, the fan 3 is set in the machine body 10, and the rectifying plate 1 can be raised and lowered. At the air inlet of the fume collecting hood 100.

[0043] The rectifying plate 1 is arranged at the air inlet of the smoke collecting hood 100 through a lifting mechanism. The lifting mechanism includes a motor 2, a push rod 22 and a support frame 23. The motor 2 is arranged in the body 10 with a hydraulic cylinder body 21, and the push rod 22 i...

Embodiment 2

[0051] Example 2, such as Figure 6 ~ Figure 11 As shown, a hinge 6 capable of adjusting the height is provided between the inner cavity wall of the smoke collecting hood 100 in this embodiment and the top surface of the rectifying plate 1 . Hinge 6 adopts damping hinge. There are three hinges 6, which are arranged on the front end and both sides of the rectifying plate 1 respectively. like Figure 8 As shown, wherein the hinge pieces 61 are connected by a damped hinge shaft 62 .

[0052] The air inlet of the smoke collecting hood 100 is located above the rectifying plate 1 and is provided with an oil screen 5. The bottom of the oil screen 5 is arranged obliquely downward from the front to the rear, and the rear end of the rectifying plate 1 protrudes from the oil screen 5 and is arranged obliquely downward. Correspondingly, the bottom of the rear end of the smoke collecting hood 100 is provided with an oil cup 4 that can collect oil droplets flowing down from the rectifyin...

Embodiment 3

[0054] Example 3, such as Figure 12 As shown, the smoke collecting hood 100 in this embodiment is also provided with an electric lifting mechanism, which includes a lifting motor 71, a fixed pulley 72 and a traction cable 73, the lifting motor 71 has a power output end; the fixed pulley 72 is two Each is located at the bottom of the body 10, and one end of the traction rope 73 is connected with the power output end of the lifting motor 71, and the other end is connected with the rectifying plate 1 by the fixed pulley 72. The traction cable 73 in this embodiment is preferably a steel wire.

[0055] The hinge in this embodiment may be a non-damping hinge. Refer to Example 2 for other structures. In this embodiment, the height adjustment of the rectifying plate 1 is realized by driving the lifting motor 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com