Black high-reflectivity solar cell backboard and a preparation method thereof

A solar cell, highly reflective technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

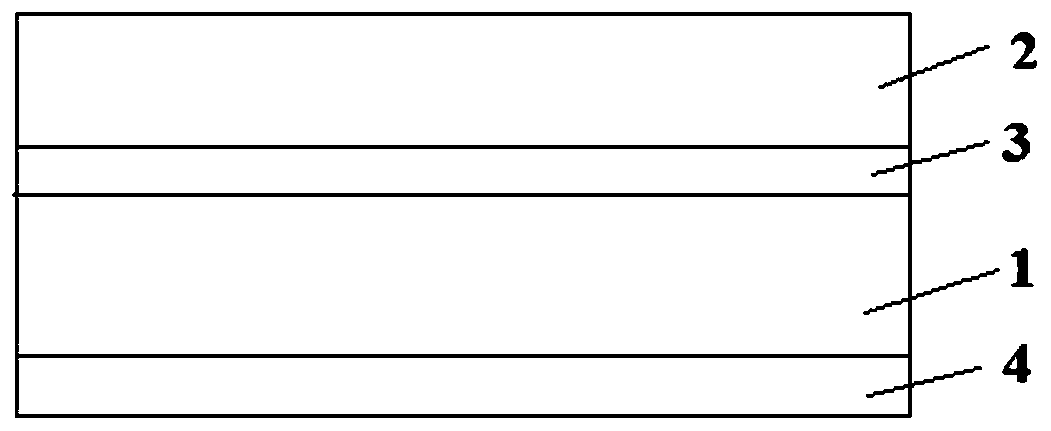

[0048] A black highly reflective solar cell back sheet in this embodiment has a four-layer structure, including a PET base layer 1 , a weather-resistant layer 2 , an adhesive layer 3 and a black functional paint layer 4 .

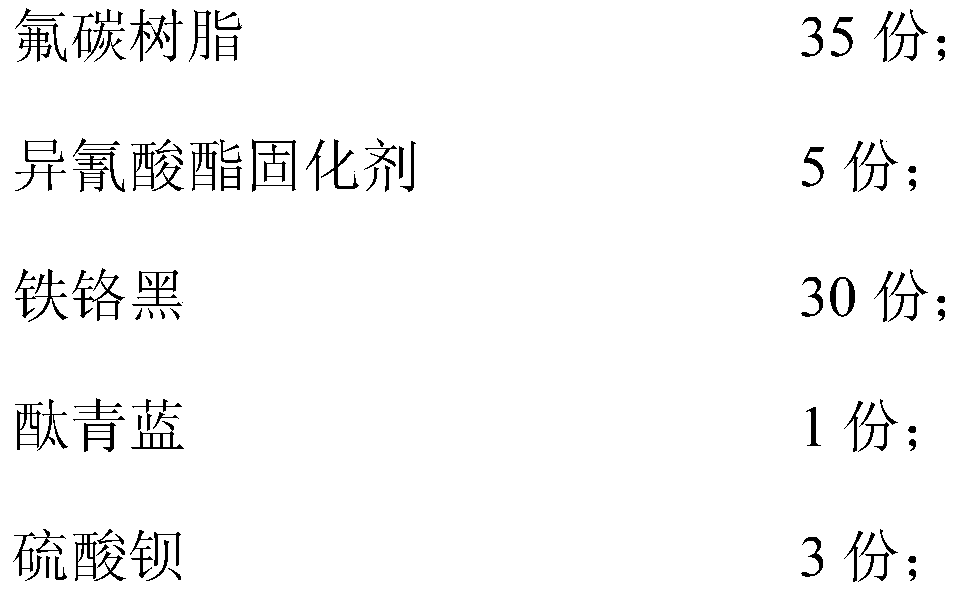

[0049] Wherein, the black functional paint layer 4 is made by coating and curing the black functional paint, and the black functional paint comprises the following components in parts by weight:

[0050]

[0051]

[0052] The PET base layer 1 is a PET film layer with a reflectivity of 95% at 400-1600nm and a thickness of 0.25mm. The weather-resistant layer 2 is a polyvinylidene fluoride film layer with a thickness of 0.02mm. The adhesive layer 3 is polyester adhesive Agent layer, its thickness is 0.01mm.

Embodiment 2

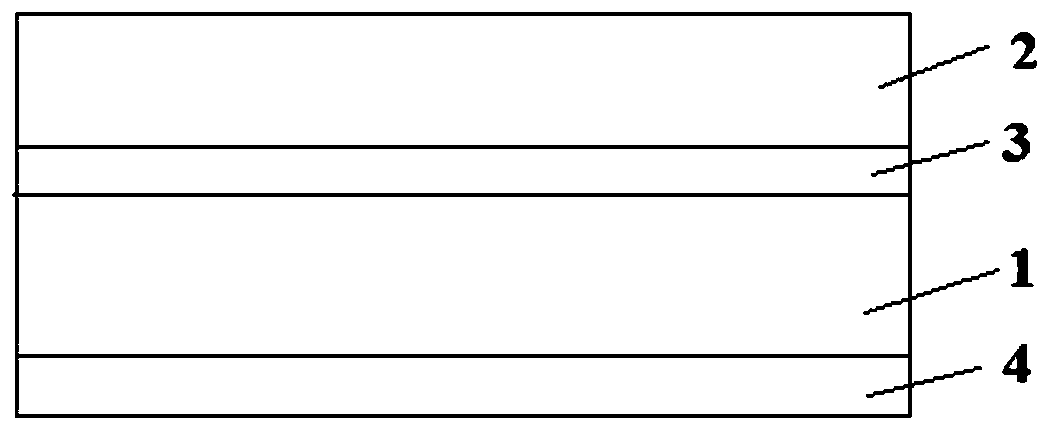

[0054] A black highly reflective solar battery backsheet in this embodiment has a four-layer structure, including a PET base layer 1 , a weather-resistant layer 2 , an adhesive layer 3 and a black functional paint layer 4 .

[0055] The black functional coating layer 4 is made by coating and curing the black functional coating, and the black functional coating comprises the following components in parts by weight:

[0056]

[0057]

[0058] The PET base layer 1 is a PET film layer with a reflectivity of 95% at 400-1600nm and a thickness of 0.28mm. The weather-resistant layer 2 is a polyethylene terephthalate layer with a thickness of 0.02mm. The adhesive layer 3 is The polyester adhesive layer has a thickness of 0.01mm.

Embodiment 3

[0060] A black highly reflective solar cell back sheet in this embodiment has a four-layer structure, including a PET base layer 1 , a weather-resistant layer 2 , an adhesive layer 3 and a black functional paint layer 4 .

[0061] The black functional coating layer 4 is made by coating and curing the black functional coating, and the black functional coating comprises the following components in parts by weight:

[0062]

[0063] The PET base layer 1 is a PET film layer with a reflectivity of 95% at 400-1600nm and a thickness of 0.25mm. The weather-resistant layer 2 is a polyvinylidene fluoride film layer with a thickness of 0.02mm. The adhesive layer 3 is a polyurethane adhesive layer with a thickness of 0.008mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com