Ceramic insulator and high voltage power capacitor insulator device

A technology of ceramic insulators and high-voltage power, applied in capacitors, insulators, lead-in/through-type insulators, etc., can solve the problems of cumbersome processing and installation operations, achieve good installation and operation, and ensure the aesthetic effect of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Example 1, ceramic insulator)

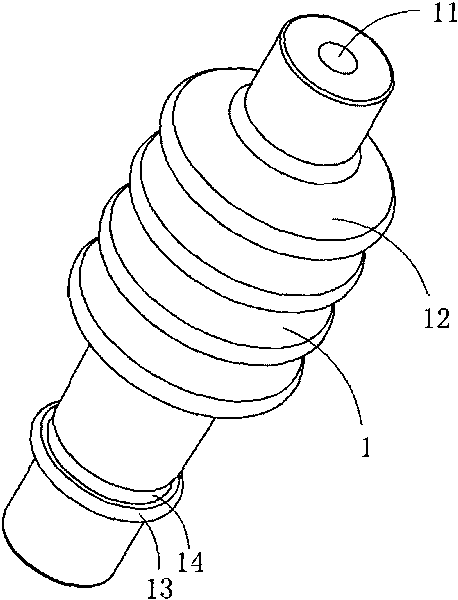

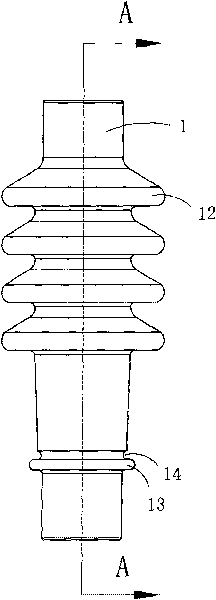

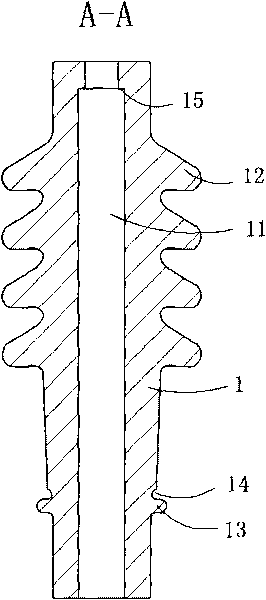

[0031] Figure 1 to Figure 3 A specific embodiment of the ceramic insulator of the present invention is shown, wherein, figure 1 It is a schematic diagram of a three-dimensional structure of a ceramic insulator in the present invention; figure 2 yes figure 1 Front view of the ceramic insulator shown; image 3 yes figure 2 The cross-sectional view of the shown ceramic insulator along line A-A.

[0032] This embodiment is a ceramic insulator for high voltage capacitors, see Figure 1 to Figure 3 , including a ceramic insulator body 1; the ceramic insulator body 1 is provided with a through hole 11 along its central axis, a plurality of sheds 12 are provided on the outer wall of the middle part of the insulator body 1, and a plurality of sheds 12 are provided on the outer wall of the lower part of the insulator body 1. There is an annular positioning boss 13 ; the insulator body 1 is also provided with an annular groove 14 between t...

Embodiment 2

[0035] (Example 2, High Voltage Power Capacitor Insulator Device)

[0036] Figure 4 to Figure 7 A specific embodiment of the high voltage power capacitor insulator device of the present invention is shown, wherein Figure 4 It is a three-dimensional structural schematic diagram of the first structure of the medium and high voltage power capacitor insulator device of the present invention; Figure 5 yes Figure 4 The schematic diagram of the three-dimensional structure of the high-voltage power capacitor insulator device when viewed from another angle; Figure 6 yes Figure 4 An exploded view of the shown high-voltage power capacitor insulator device; Figure 7 yes Figure 4 A half-section structural view of the high-voltage power capacitor insulator device shown.

[0037] This embodiment is a high-voltage power capacitor insulator device, see Figure 4 to Figure 7 , including a ceramic insulator body 1, a wiring assembly 2 arranged at the top of the ceramic insulator bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com