Labeler

A labeling machine and labeling technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of unsightly barcodes, labor-intensive, affecting work efficiency, etc., to save manpower, ensure beauty, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

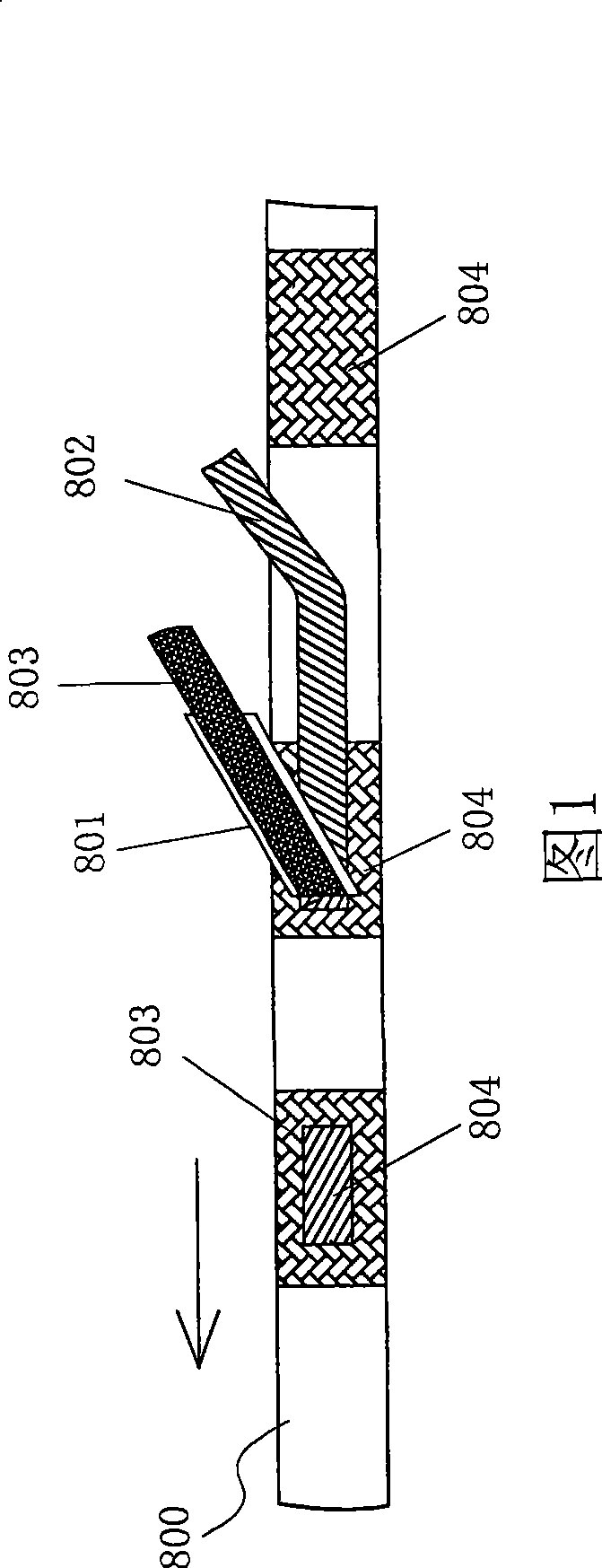

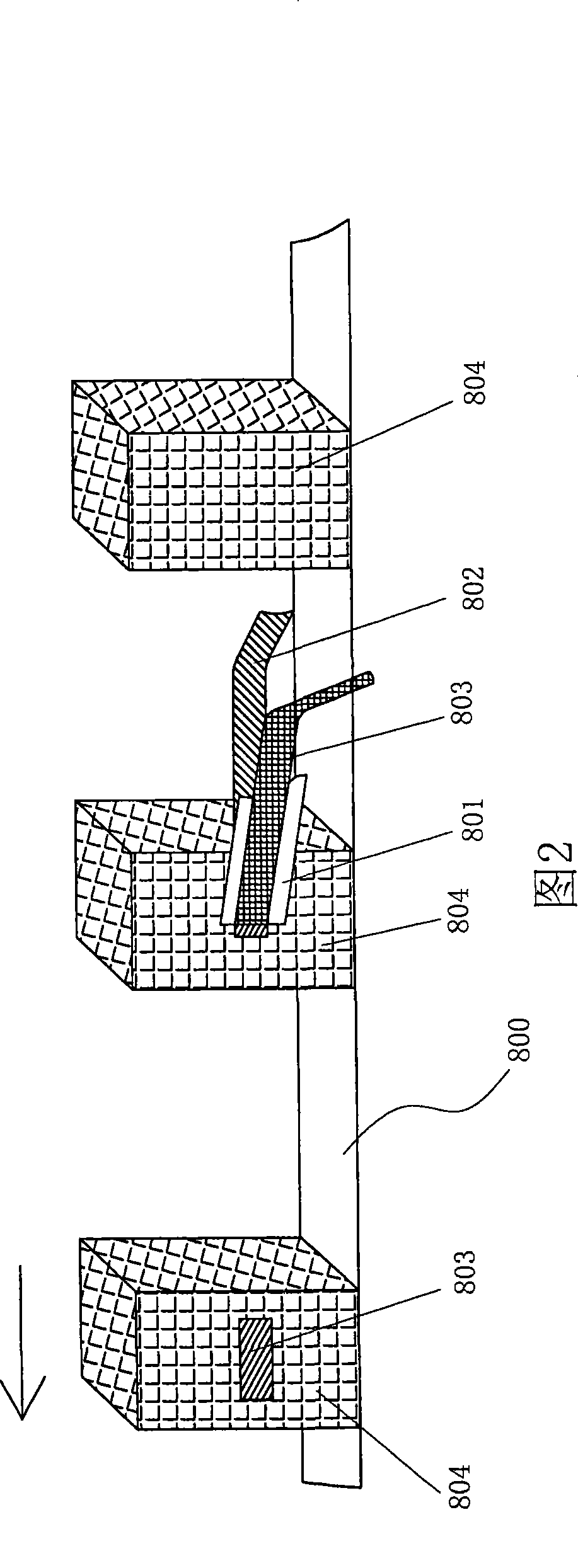

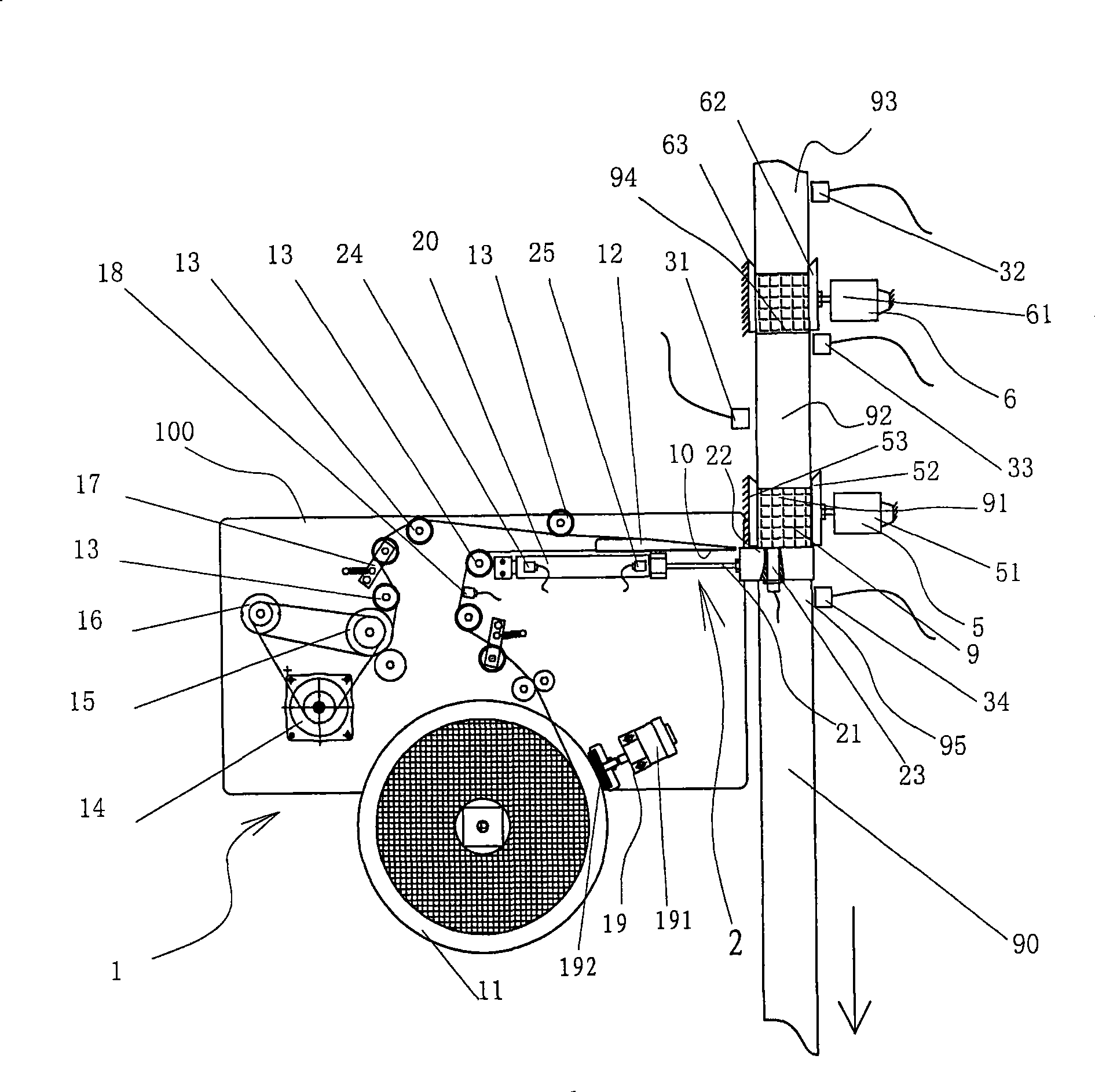

[0042] like image 3 - shown in Figure 9, the labeling machine of the present invention comprises:

[0043] A label feeding and conveying device 1 for feeding and conveying labels to a predetermined label picking position 10;

[0044] A label application device 2 having a telescopic rod 21 that can be freely extended and retracted in a retracted position and an extended position, and a pick-up and application member 22 provided at the end of the telescopic rod 21, the retracted position being set so that the pick-up The applicator member 22 is located in said predetermined label pick-up position 10 for picking up labels from the label feed conveyor 1, said extended position being set so that when the product 9 to be labeled is in the predetermined applicator position 91 . The pick-and-apply member 22 protrudes above the conveyor chain 90 that conveys the product 9 to be labeled and is located on the front side of the product 9 to be labeled in the conveying direction, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com