Physical simulation experiment system and method of deep-tunnel high-resistance extensible anchor pole support

A technology of bolt support and physical simulation, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of not reflecting surrounding rock, limited elongation of bolts, loss, etc. Achieve the effect of saving experiment cost, saving experiment time and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

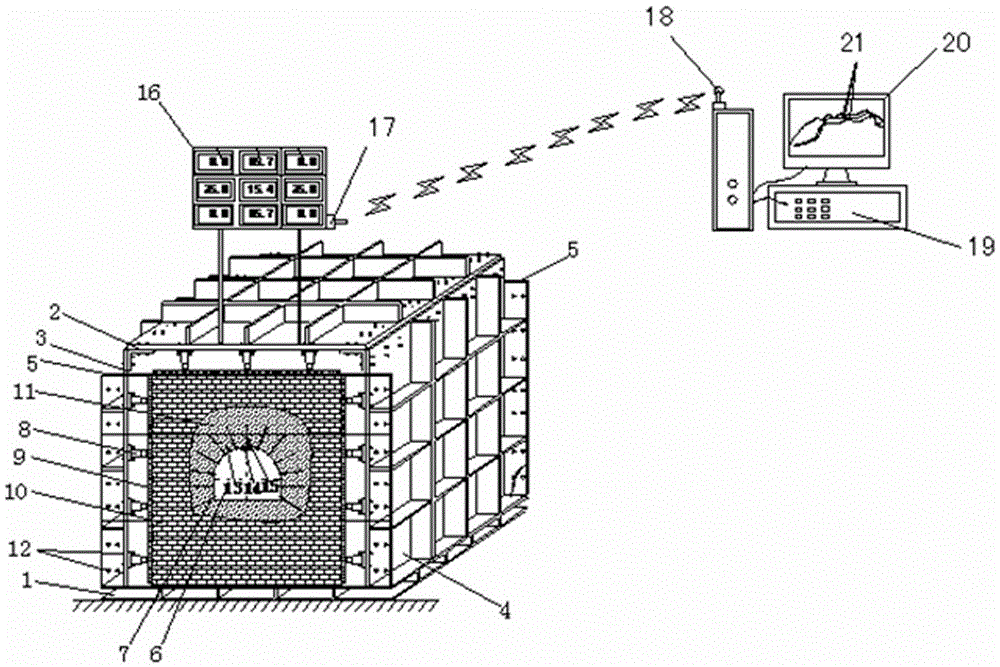

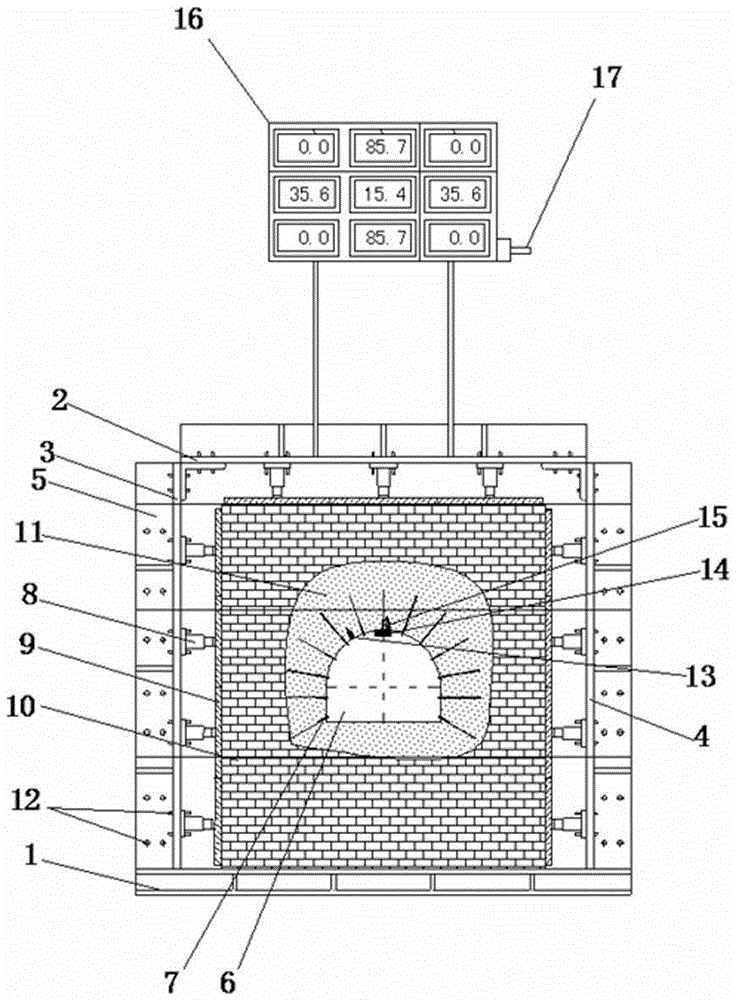

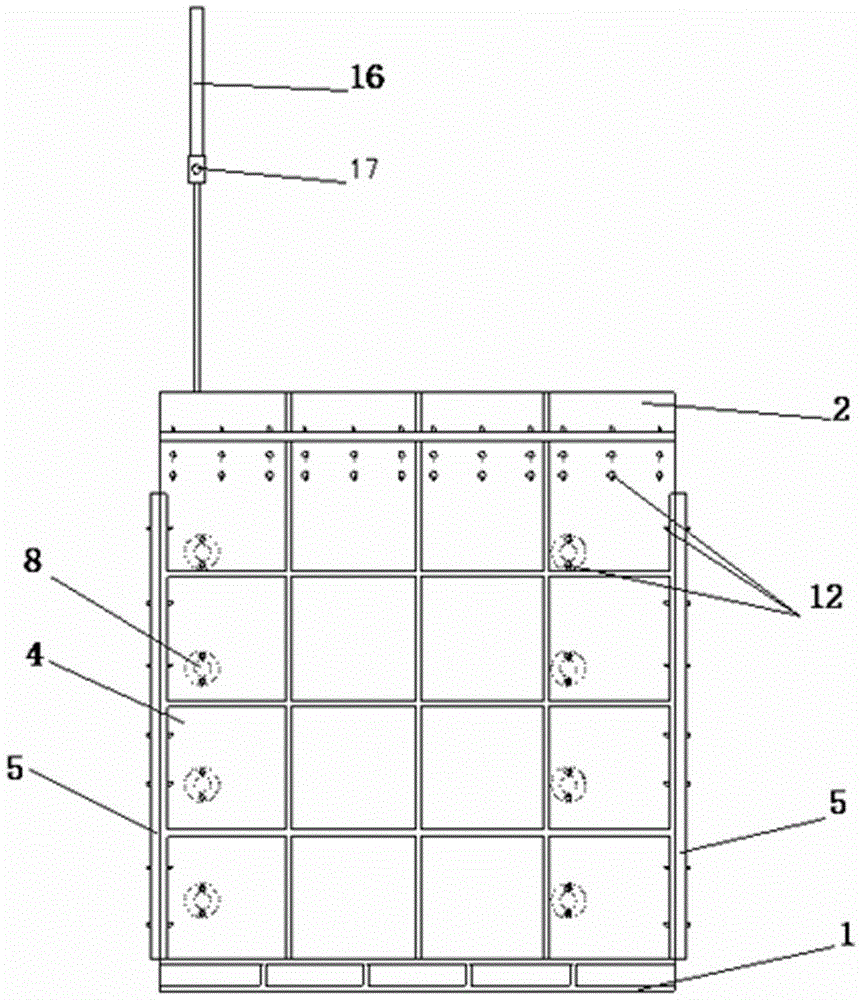

[0036] Such as figure 1As shown, the physical simulation experiment system of high-resistance extensible bolt support in deep roadway of the present invention includes a simulation test bench, a mold pressure loading device, a high-resistance extensible anchor rod 7, rock mass 10 outside the anchorage area, and Area rock mass 11, roadway 6, surrounding rock displacement sensor 13, bolt dynamometer 14, rod tail casing displacement sensor 15, digital display screen 16, data transmitting device 17, data receiving device 18, data processing device 19, display 20. The simulation test bench includes a load-bearing bottom plate 1, a load-bearing cover plate 2, a load-bearing left side plate 3, a load-bearing right side plate 4, and front and rear tempered glass side plates 5. The load-bearing cover plate 2, load-bearing left side plate The side plate 3 and the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com