Top beam of hydraulic support

A technology of hydraulic support and roof beam, which is applied in the direction of supporting the roof beam of the mine roof, mining equipment, earth square drilling and mining, etc., can solve the problem of affecting the unit and pedestrian passage space, which can not be solved well and cannot be kept constant Resistance support and other issues, to achieve the effect of weight reduction, small impact, and improved support resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

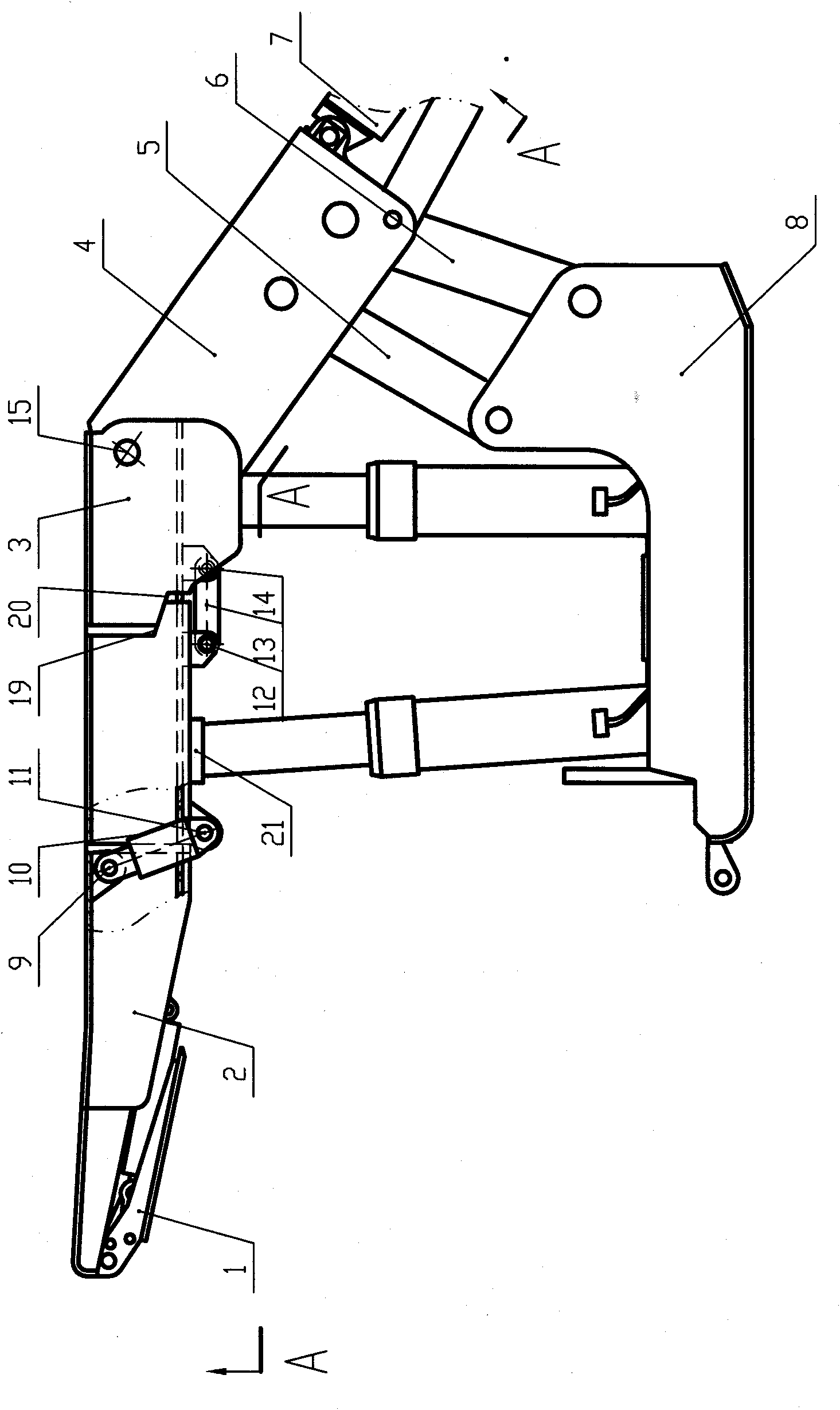

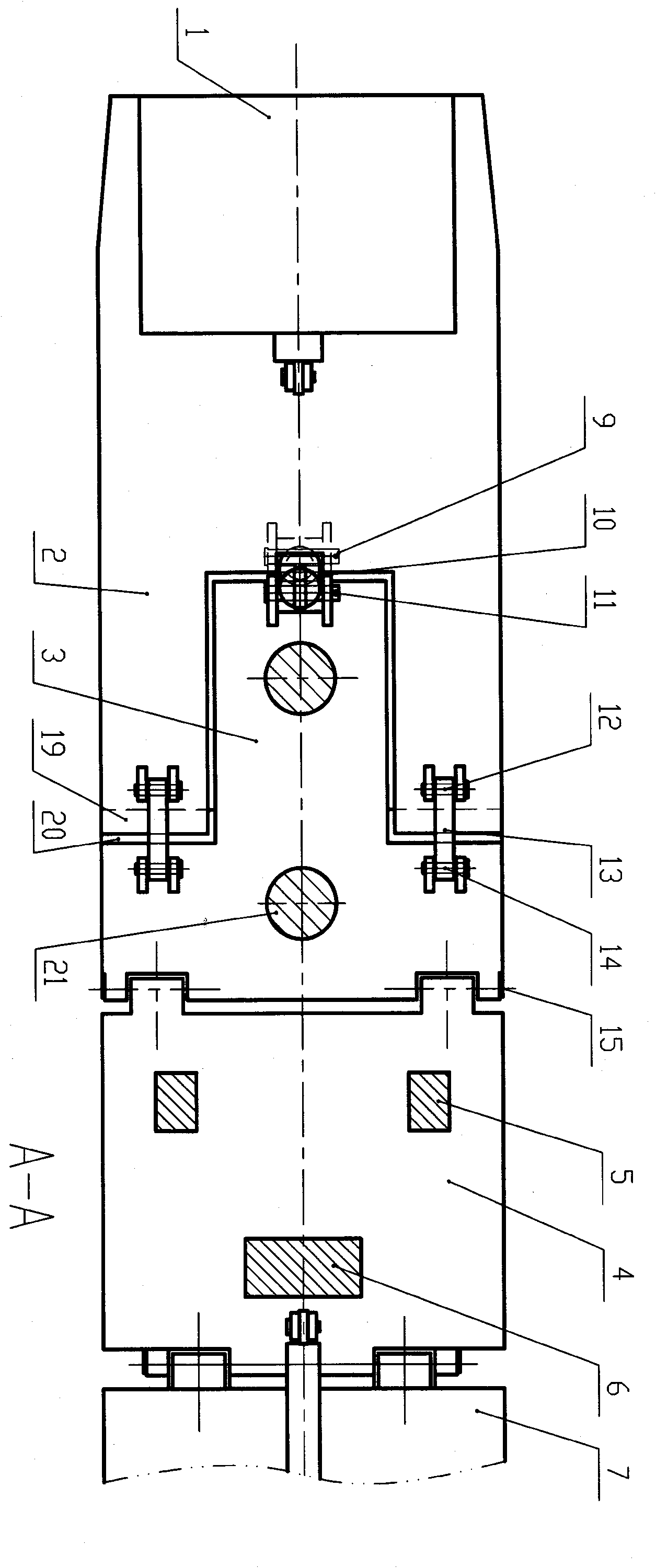

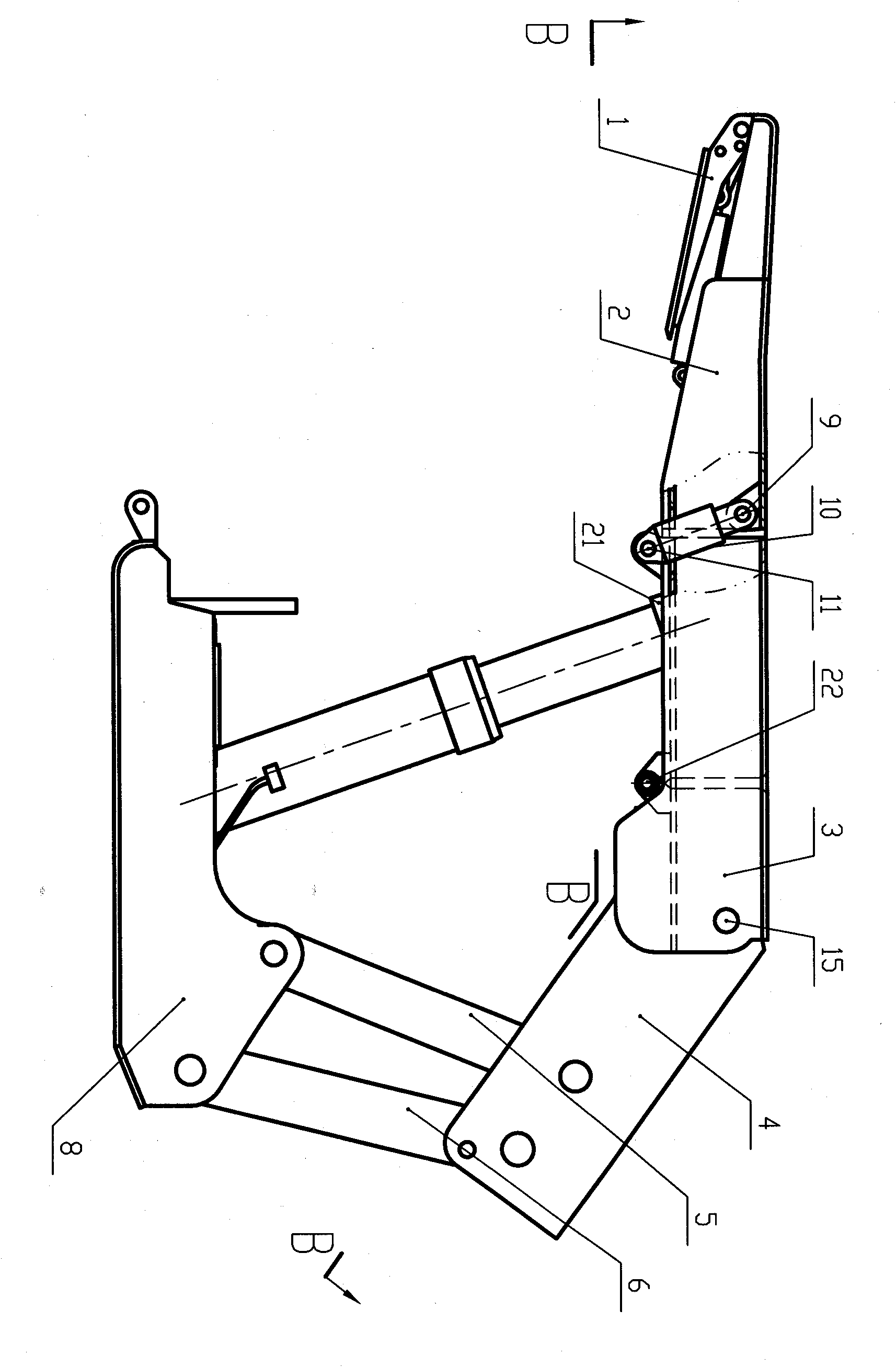

[0022] combine figure 1 and figure 2 , the first embodiment of the top beam of the hydraulic support of the present invention is to apply the present invention to another purchased patent belonging to the supporting shield type hydraulic support. Of course, it can also be applied to the common four-column support shielding hydraulic support. Concave auxiliary top beam body 2 without column socket 21 including front end hinged forward beam; convex main top beam body with column socket 21 matching with the concave part of auxiliary top beam body 2 3. The auxiliary top beam body 2 and the main top beam body 3 are inlaid together to form a top beam; the front beam jack 10 is hinged with the auxiliary top beam body 2 through the pin 9, and hinged with the main top beam body 3 through the pin 11; 12 is hinged with the auxiliary top beam body 2 and two connecting rods 13 hinged with the main top beam body 3 through the pin 14; the column socket 21 for connecting the hydraulic prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com