Fully-enclosed integral assembly grid concrete support method

A concrete and fully enclosed technology, which is applied in the direction of earthwork drilling, bolt installation, shaft equipment, etc., can solve problems that restrict the smooth production of mines, achieve rapid and effective support, uniform force, and avoid local stress concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

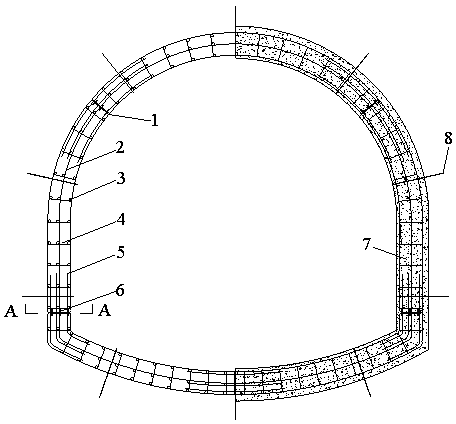

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

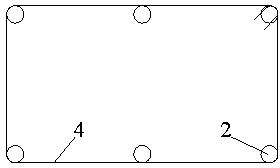

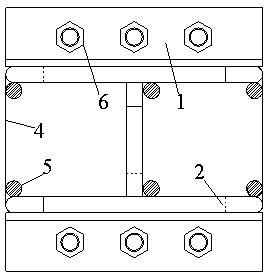

[0018] In the fully-enclosed integrally assembled grid concrete support method of the present invention, after the anchor net cable is sprayed once for support according to the conventional method of the prior art, fully enclosed integrally assembled grid supports are implemented at intervals in the roadway, and the concrete support method is poured. Concrete provides secondary permanent support for the roadway. The components used include angle steel 1, main reinforcement 2, connecting reinforcement 3, stirrup 4, reinforcing rib 5, bolt 6, grouting pipe 8, and the grouting pipe 8 is a steel pipe with internal thread. After the support is sprayed once with the anchor mesh cable, the number of grid components divided by each group of grid supports, the size of the main reinforcement 2, the stirrup 4 and the angle steel 1 of the grid are determined according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com