Broken type soft rock roadway supporting device and method based on concrete filled steel tube support

A technology of steel tube concrete and reinforced concrete, which is applied in the direction of earthwork drilling, tunnel, tunnel lining, etc., to achieve the effect of good support effect, high support resistance and strength improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

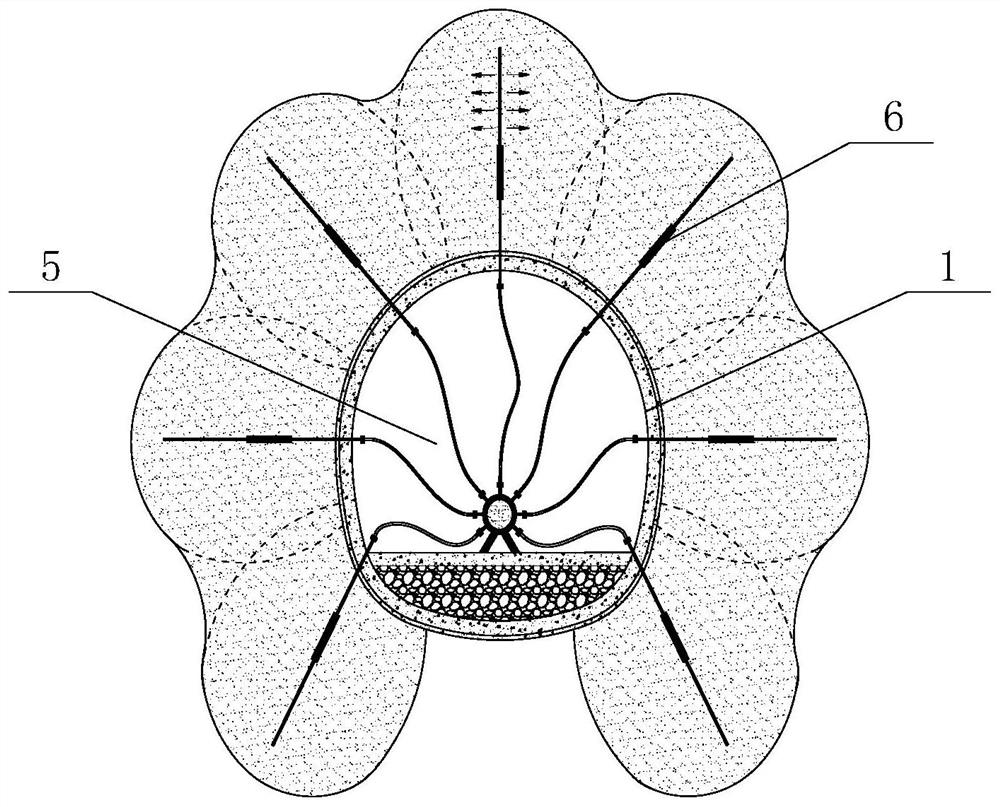

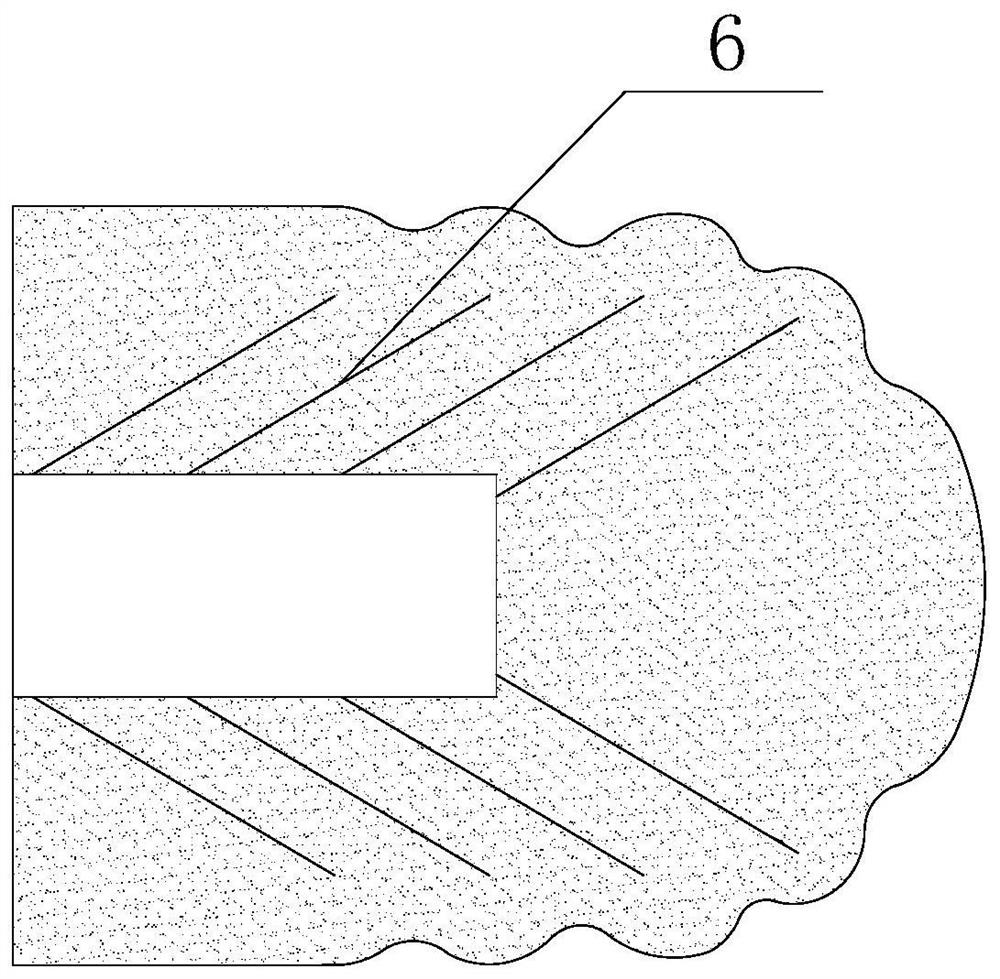

[0077] A support device for broken-type soft rock roadway based on concrete filled steel tube bracket, a plurality of hollow grouting bolts 6 are placed in the surrounding rock of the roadway, and the grouting bolts are used to inject pressure injection into the surrounding rock. slurry. The cross-sectional shape of the roadway 5 is circular or flat oval.

[0078] A concrete layer is shot on the surrounding rock of the roadway (here, the shotcrete is to break the rock surface of the roadway into a whole), and a layer of high-strength plastic plate 4 (compressive strength above 250kPa) is covered on the concrete layer. 4 Thickness is 100mm.

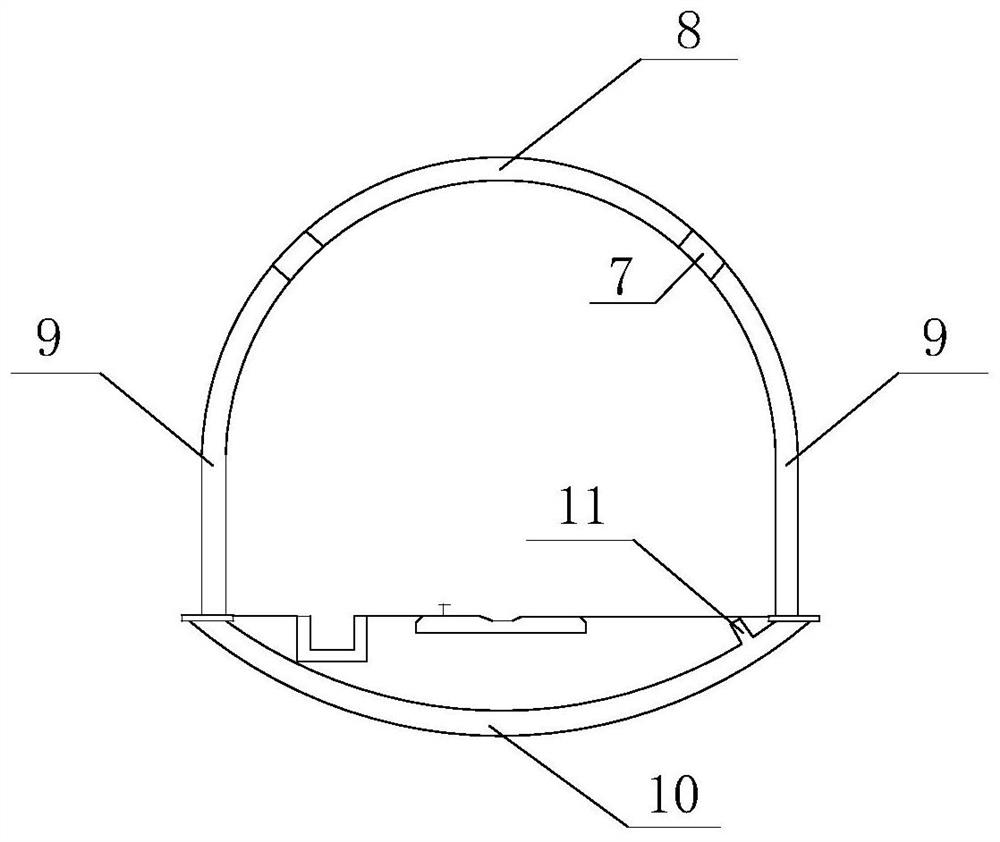

[0079] At a certain distance from the plastic plate 4 (the distance is usually 50-60mm), the flexural and early-strength concrete-filled steel tubular support structure 1 is erected. The flexural and early-strength concrete-filled steel tubular support structure includes a plurality of individual supports. In the outer welding method, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com