Double column-type transition hydraulic support

A hydraulic support and column type technology, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficulty in automation, unbalanced force on front and rear columns, damage to columns and components, etc., and achieve electro-hydraulic control and automation, easy electro-hydraulic control and automation, simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

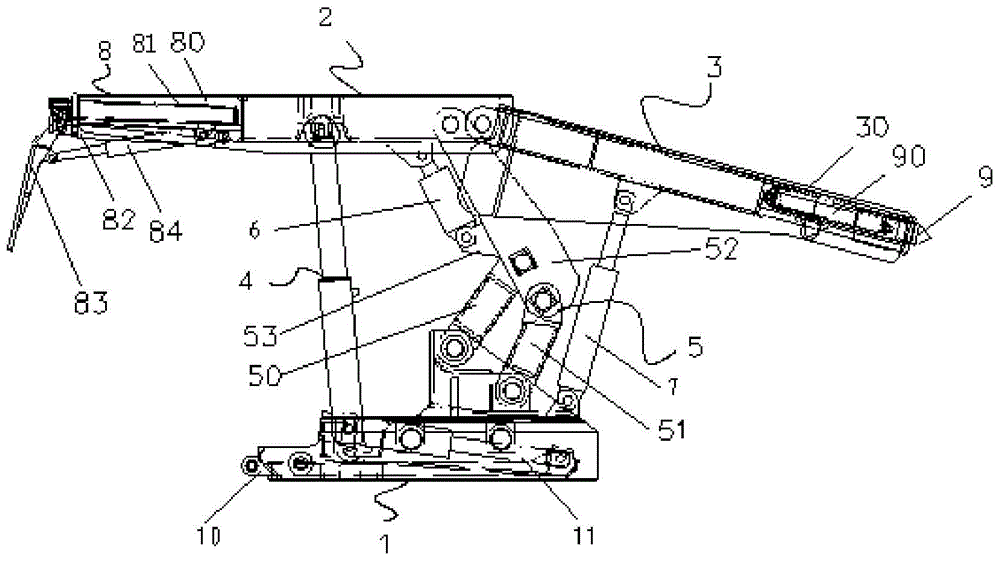

[0019] figure 1 It is a structural schematic diagram of the two-column transition hydraulic support of the present invention; figure 1 As shown, the two-column transition hydraulic support of the present invention includes: a base 1; a top beam 2 arranged above the base 1; a tail beam 3 hinged at one end of the top beam 2; a top beam supporting device installed on the base 1 , is connected with the top beam 2; the tail beam supporting device installed on the base 1 is connected with the tail beam 3. The below of the top beam 2 and the below of the tail beam 3 respectively form spaces for arranging the front and rear scraper heads and the tail driving parts.

[0020] Specifically, such as figure 1 As shown, the two-column transition hydraulic support of the present invention has a top beam 2, and one end of the top beam 2 is hinged with a tail beam 3. A pair of columns 4 are symmetrically arranged front and back ( figure 1 One column 4 shown in will cover the other column s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com