Polytetrafluoroethylene composite material and product preparation method thereof

A technology of polytetrafluoroethylene and composite materials, which is applied in the field of composite materials and its preparation, can solve the problems of low cost performance, non-wear resistance, poor creep resistance, etc., and achieve the effects of cost reduction, performance improvement, and thermal conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

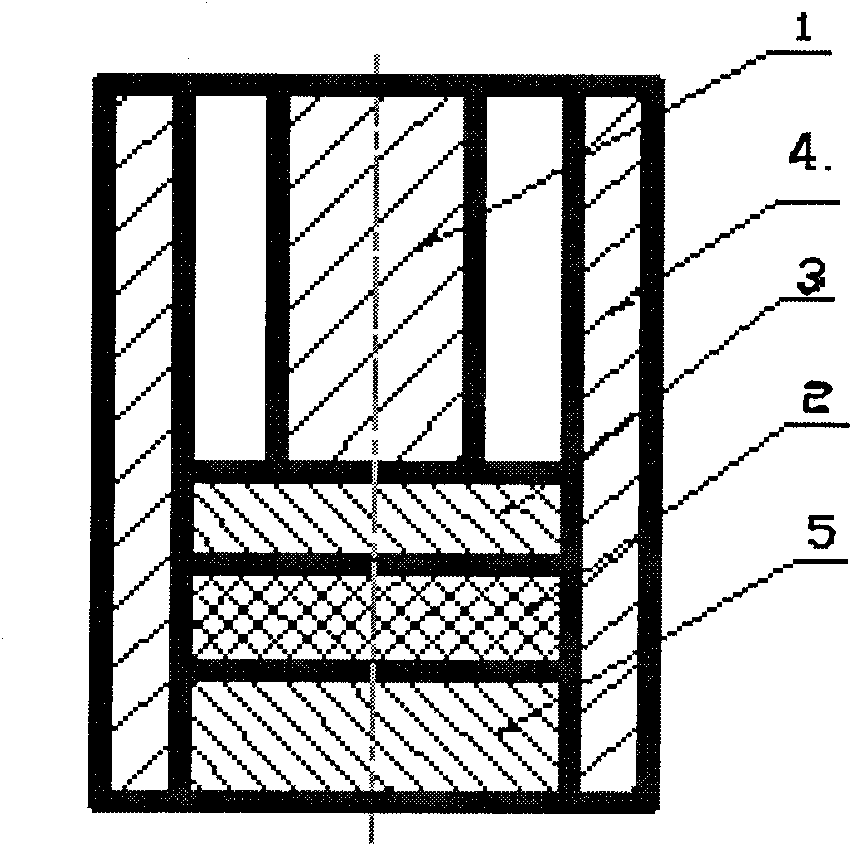

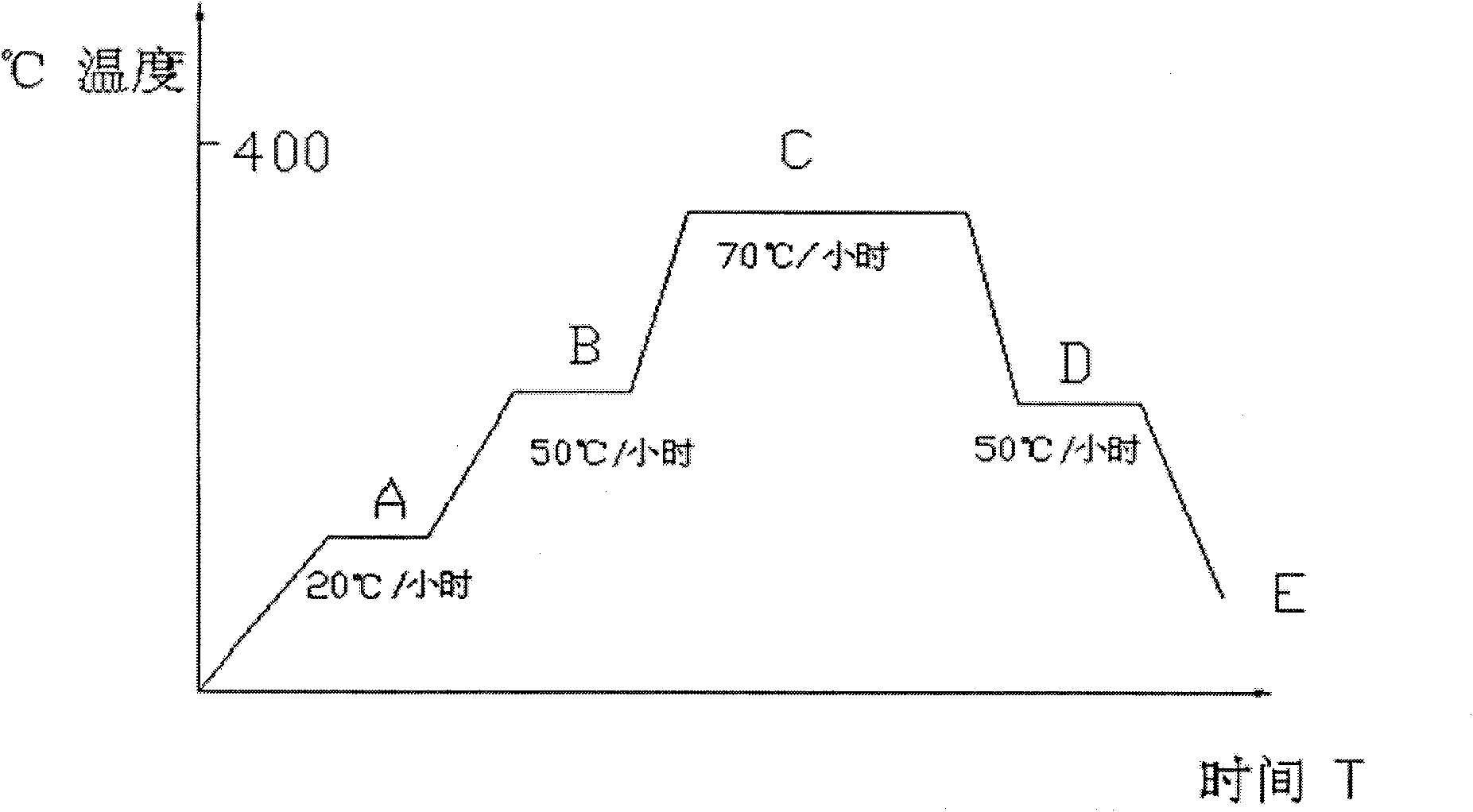

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] An overview of the method follows:

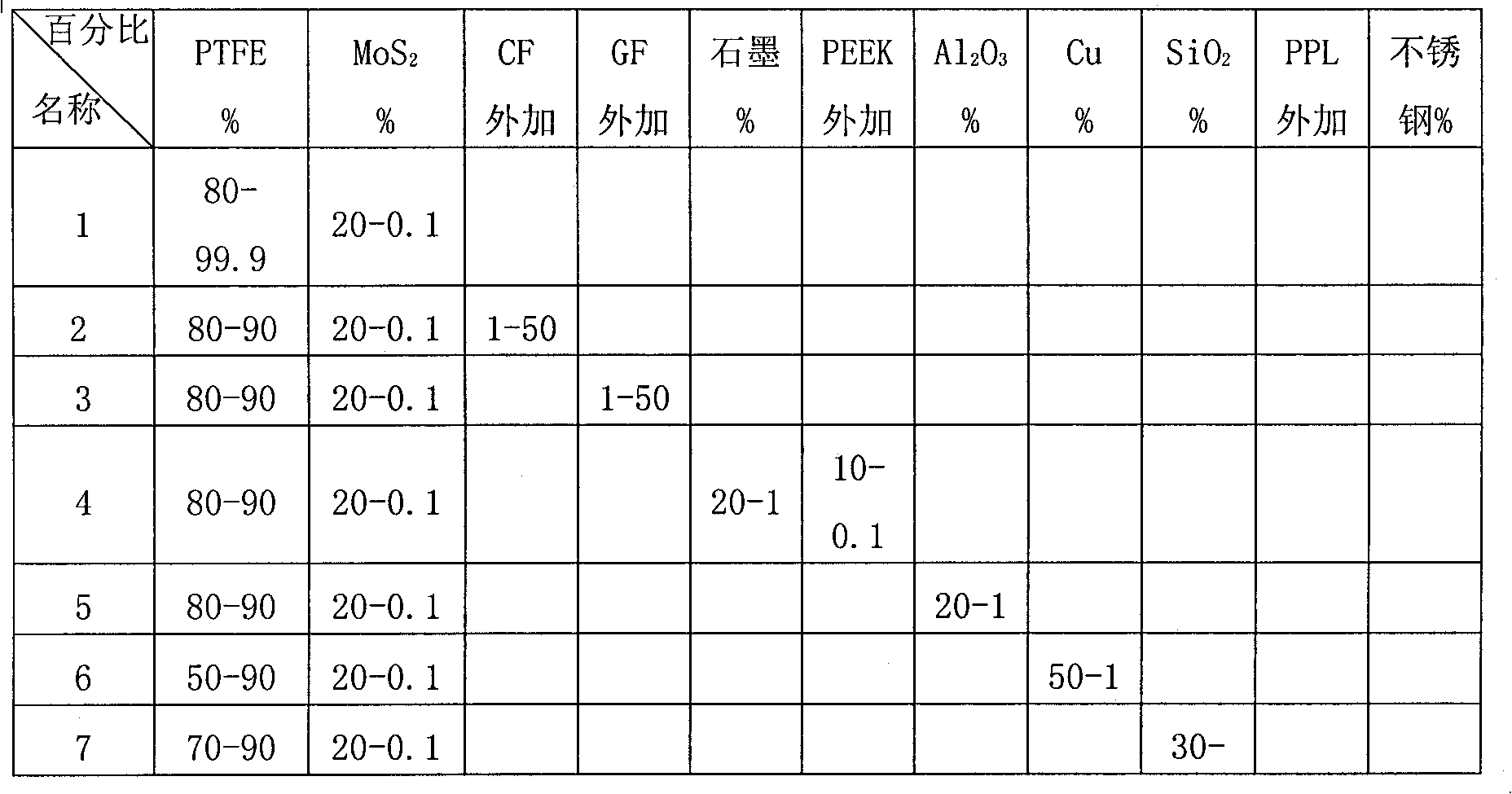

[0026] 1. A polytetrafluoroethylene composite material, whose components include one or more of molybdenum disulfide, aluminum oxide, copper powder, graphite, silicon dioxide or stainless steel powder, and polytetrafluoroethylene; the polytetrafluoroethylene The tetrafluoroethylene composite material is a binary polytetrafluoroethylene composite material, wherein the weight percentage of polytetrafluoroethylene is 80-99.9%, and the balance is other components. The preferred component is polytetrafluoroethylene with a weight percentage of 92-99.9%, and the balance is other components.

[0027] The improvement of this material includes: adding polyether ether ketone (PEEK) or polyphenylene resin (PPL) on the basis of 100% of the above weight, the proportion of polyether ether ketone added is 0.1-80% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com