Preparation method for vertically oriented boron nitride/high polymer insulating heat conducting material

A vertically oriented, boron nitride technology, applied in heat exchange materials, chemical instruments and methods, layered products, etc., can solve problems such as difficulty in improving the thermal conductivity of the substrate, expand the scope of application, and easily control the process flow , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

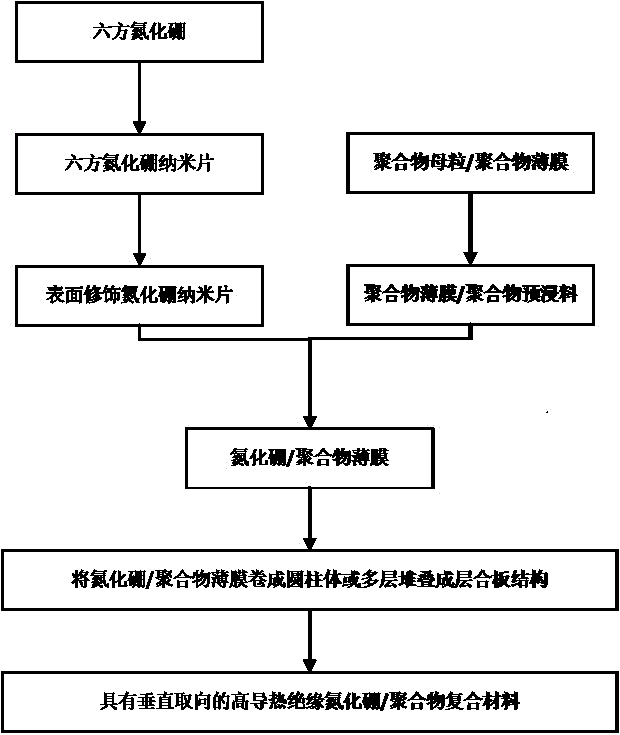

[0025] Correspondingly, the embodiments of the present invention provide a method for preparing the above-mentioned high thermal conductivity insulating composite material with a vertically oriented structure. The process steps of the preparation method of the high thermal conductivity polymer composite material of the embodiment of the present invention are as follows: figure 1 As shown, it includes the following steps:

[0026] Step 1: Add boron nitride with a mass fraction of 0.5%~2% to the mixed solution of water and ethanol (mass ratio 1:1~1:5), mix and sonicate for 0~24 hours to obtain boron nitride nanosheets mixed solution;

[0027] Preferably, the water used above is deionized water; the ethanol is absolute ethanol. The particle size of boron nitride raw material is 2~18μm;

[0028] Step 2, adding mass fraction of 0.1-0.2% tris to the mixed solution, using dilute hydrochloric acid to adjust the pH to 8-9, adding mass fraction of 0.2-2% dopamine hydrochloride, Afte...

Embodiment 1

[0039] A high thermal conductivity polymer composite material and a preparation method thereof. The high thermal conductivity polymer composite material provided in Example 1 was prepared according to the following method.

[0040] 1. Preparation of Surface Modified Boron Nitride Nanoparticles

[0041] (1). Using commercial boron nitride sheets as the basic raw material, add boron nitride with a mass fraction of 0.5% to a mixed solution of water and ethanol (mass ratio: 1:3), mix and sonicate for 12 hours to obtain boron nitride Nanosheet mixed solution;

[0042] (2). Add 0.1% trishydroxymethylaminomethane to the mixed solution, adjust the pH to 8.5 with dilute hydrochloric acid, then add dopamine hydrochloride with a mass fraction of 0.5%, and mix to obtain a mixture solution . The above solution was stirred for 12 hours in a dark environment;

[0043] (3). Add a silane coupling agent such as KH570 with a mass fraction of 1% to the above mixed solution, and then use dilu...

Embodiment 2

[0052] A high thermal conductivity polymer composite material and a preparation method thereof. The high thermal conductivity polymer composite material provided in Example 2 was prepared according to the following method.

[0053] 1. Preparation of Surface Modified Boron Nitride Nanoparticles

[0054] (1). Using commercial boron nitride sheets as the basic raw material, add boron nitride with a mass fraction of 0.5% to a mixed solution of water and ethanol (mass ratio: 1:3), mix and ultrasonically treat for 6 hours to obtain boron nitride Nanosheet mixed solution;

[0055] (2). Add 0.1% trishydroxymethylaminomethane to the mixed solution, adjust the pH to 8.5 with dilute hydrochloric acid, then add dopamine hydrochloride with a mass fraction of 0.5%, and mix to obtain a mixture solution . The above solution was stirred for 6 hours in a dark environment;

[0056] (3). Add 1% silane coupling agent such as KH550 to the above mixed solution

[0057] (4). After the above mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com