Two-dimensional slice material enhanced metal-based composite

A technology of composite materials and two-dimensional sheets, which is applied in the field of metal matrix composite materials, can solve the problems of thermal conductivity and electrical conductivity of lossy metal substrates, and achieve the effects of improving thermal conductivity, avoiding mechanical properties, and alleviating high thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the metal matrix composite material is based on nickel, and the Mxenes material Ti 3 C 2 T x Composite bulk material as reinforcement phase, where Ti 3 C 2 T x The particles are uniformly dispersed in the nickel matrix particles.

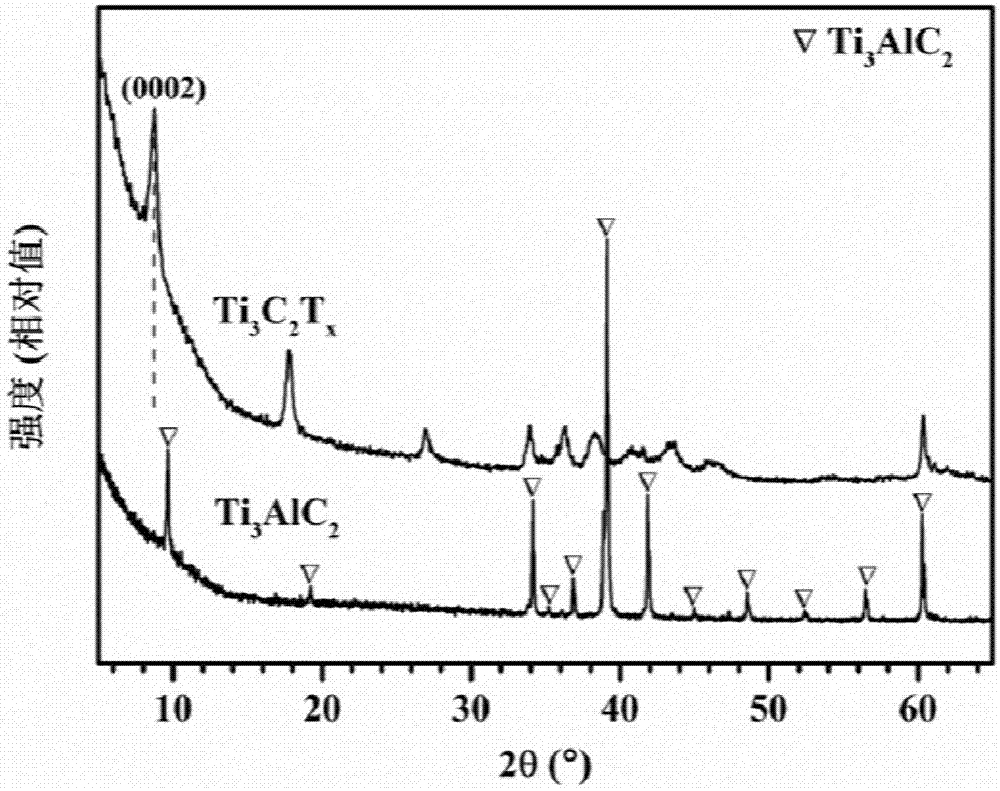

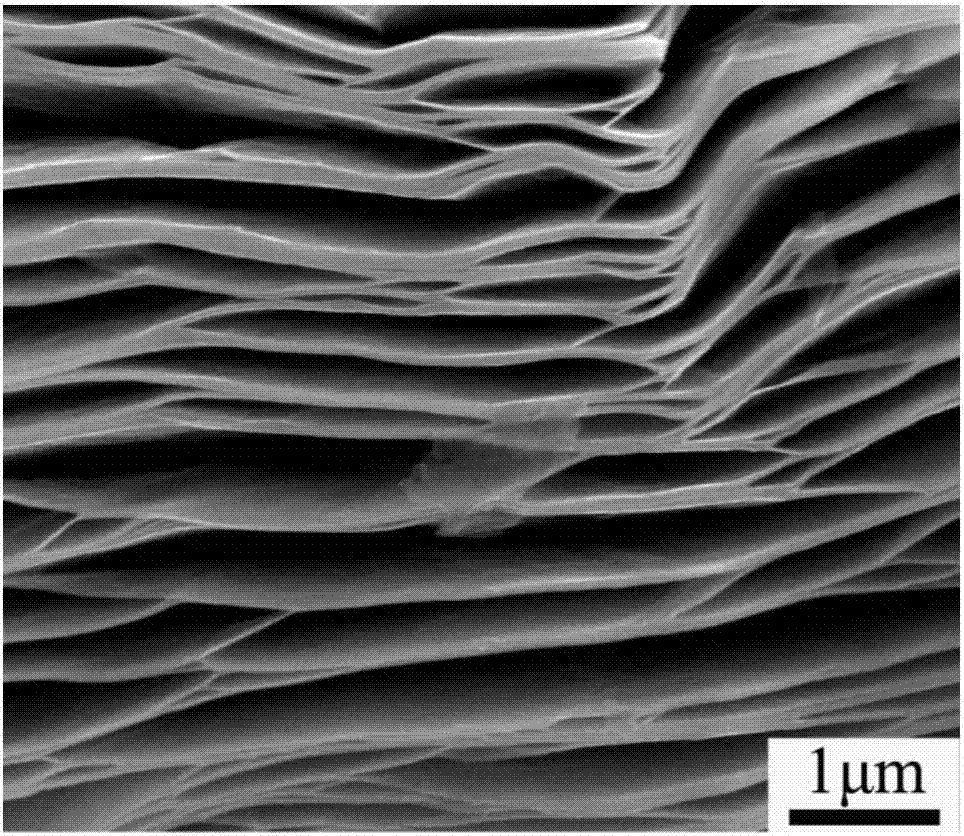

[0023] The above Ti 3 C 2 T x By combining the ternary layered cermet Ti 3 AlC 2 The Al atoms in the phase are extracted from the system. To the Ti 3 C 2 T x The powder is subjected to XRD diffraction pattern analysis, the results are as follows figure 1 , showing that the solid product is Ti 3 C 2 T x , where the molar ratio of Ti to C is Ti:C>1:1, that is, Ti 3 C 2 T x Contains carbon vacancies. To the Ti 3 C 2 T x The powder was analyzed by SEM, the results are as follows figure 2 As shown, the solid product was shown to be multi-layered accordion-shaped.

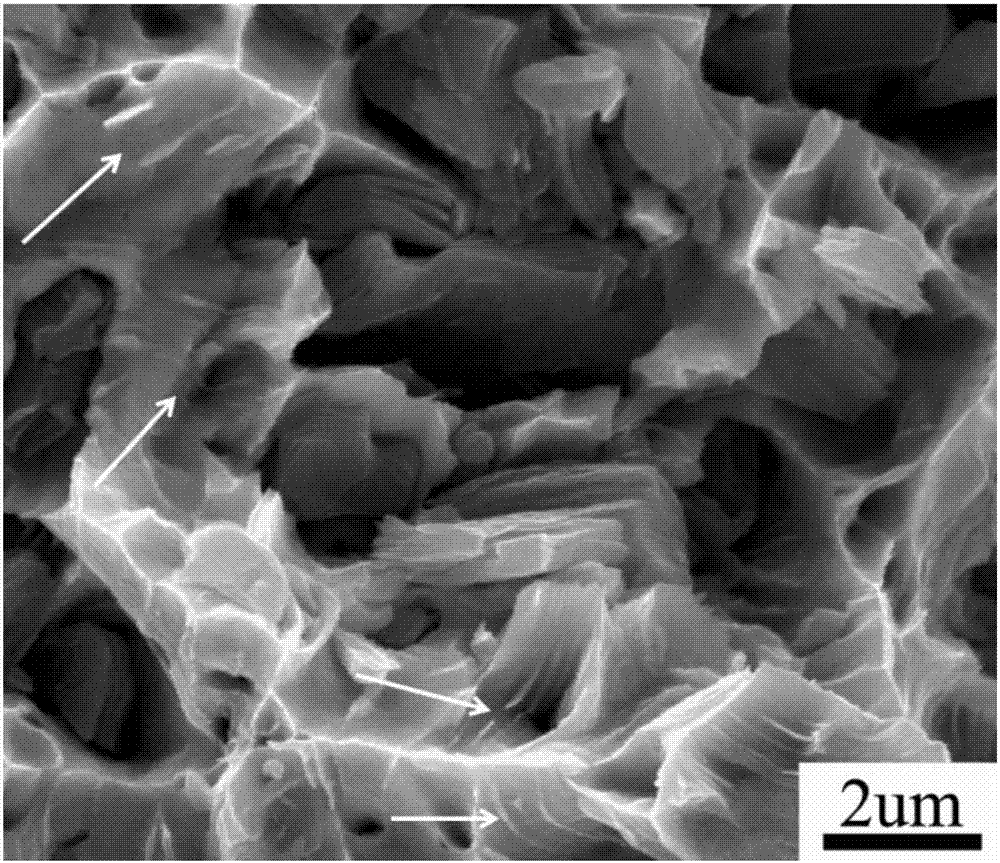

[0024] The composite material block is obtained by SPS sintering its powder, and the composite material powder is prepared by powder metall...

Embodiment 2

[0031] In this embodiment, the metal matrix composite material is based on copper, and the Mxenes material Ti 3 C 2 T x The composite material block is the reinforcing phase, where Ti 3 C 2 T x The particles are uniformly dispersed in the copper matrix particles.

[0032] Same as Example 1, the Ti 3 C 2 T x By combining the ternary layered cermet Ti 3 AlC 2 The Al atoms in the phase are extracted from the system. To the Ti 3 C 2 T x The powder is subjected to XRD diffraction pattern analysis, the results are as follows figure 1 , showing that the solid product is Ti 3 C 2 T x , where the molar ratio of Ti to C is Ti:C>1:1, that is, Ti 3 C 2 T x Contains carbon vacancies. To the Ti 3 C 2 T x The powder was analyzed by SEM, and the results were similar figure 2 As shown, the solid product was shown to be multi-layered accordion-shaped.

[0033] For the Ti used above 3 C 2 T x The powder is subjected to XRD diffraction pattern analysis, the results ar...

Embodiment 3

[0041] In this embodiment, the metal matrix composite material is based on magnesium, and Mxenes material Ti 3 C 2 T x The composite material block is the reinforcing phase, where Ti 3 C 2 T x The particles are uniformly dispersed in the magnesium matrix particles.

[0042] Same as Example 1, the Ti 3 C 2 T x By combining the ternary layered cermet Ti 3 AlC 2 The Al atoms in the phase are extracted from the system. To the Ti 3 C 2 T x The powder is subjected to XRD diffraction pattern analysis, the results are as follows figure 1 , showing that the solid product is Ti with carbon vacancies 3 C 2 T x . To the Ti 3 C 2 T x The powder was analyzed by SEM, and the results were similar figure 2 As shown, the solid product was shown to be accordion-shaped.

[0043] The composite material block is obtained by SPS sintering its powder, and the composite material powder is prepared by a solution in situ reduction method. The specific preparation method is basica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com