Graphene-aluminum oxide hybrid reinforced copper-based composite material and preparation method thereof

A copper-based composite material and composite material technology, applied in the field of preparation of copper-based composite materials, can solve the problems of residual graphene oxide, unsatisfactory other performance indicators, cumbersome steps, etc., and achieve improved uniform dispersion and improved wetting The combination of sex and interface and the effect of preparation process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of this composite material comprises the steps:

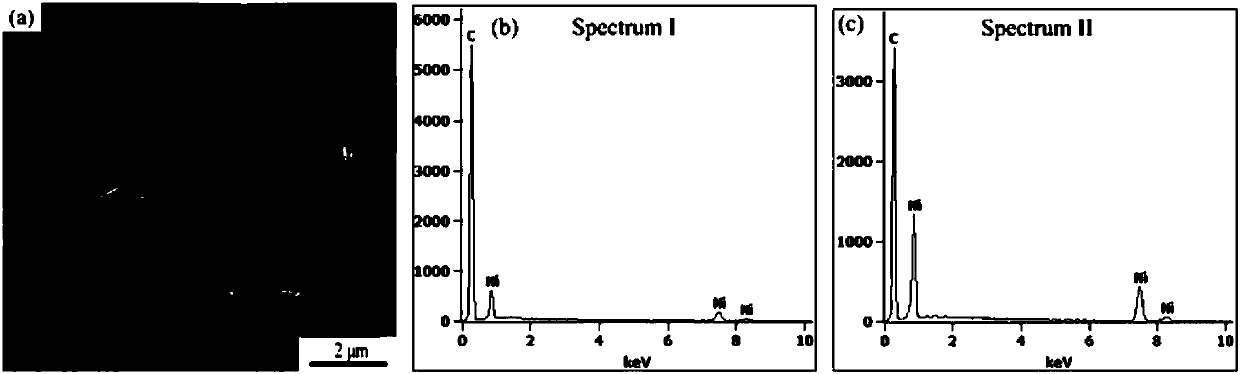

[0043] S1: Put the graphene in an ultrasonic container for ultrasonic dispersion for 2 hours, and take the ultrasonically dispersed graphene and immerse it in SnCl 2 In the sensitization solution, ultrasonically disperse for 30 minutes again, take it out, filter it, and wash it with deionized water several times; then put the graphene after the sensitization treatment into the palladium sink solution to activate, then ultrasonically disperse it for 30 minutes, take it out and filter it, and use The deionized water was washed several times and then used; finally, the surface of the sensitized and activated graphene particles was treated with electroless nickel plating to obtain graphene@Ni.

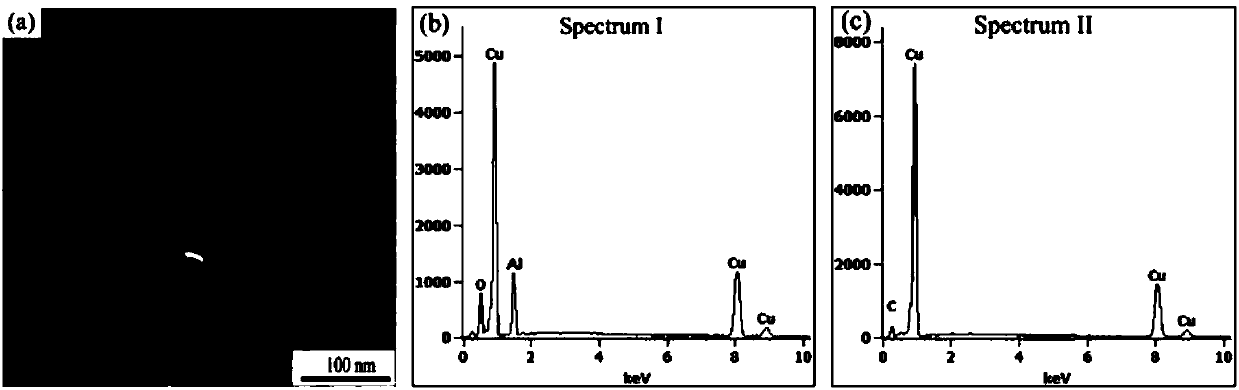

[0044] S2: Put the Cu-Al alloy powder in a ball mill tank for in-situ reaction ball milling to obtain Cu-Al 2 o 3 Composite powder.

[0045] S3: placing the composite powder obtained in the step S2 in an alc...

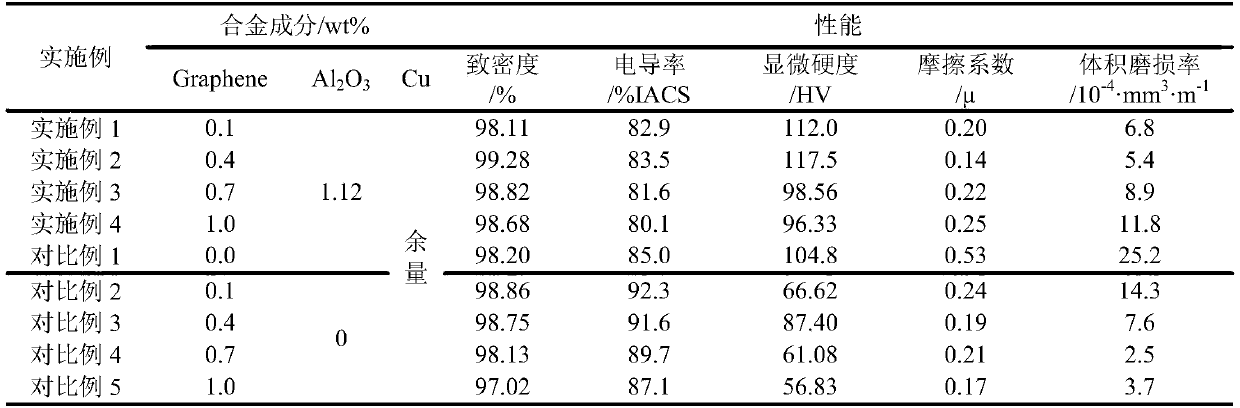

Embodiment 1

[0056] A kind of preparation method of graphene-alumina hybrid reinforced copper-based composite material, described method is carried out according to the following steps:

[0057] S01: Place graphene nanosheets with a thickness of 0.1-3nm and a diameter of 1-2μm in an ultrasonic container for ultrasonic dispersion for 2 hours, and take the ultrasonically dispersed graphene and immerse it in SnCl 2 In the sensitization solution, ultrasonically disperse for 30 minutes again, take it out, filter it, and wash it with deionized water several times; then put the graphene after the sensitization treatment into the palladium sink solution to activate, then ultrasonically disperse it for 30 minutes, take it out and filter it, and use The deionized water was washed several times and then used; finally, the surface of the sensitized and activated graphene particles was treated with electroless nickel plating to obtain graphene@Ni.

[0058] S02: Put Cu-0.6wt%Al (mass percentage) atomize...

Embodiment 2

[0064] A kind of preparation method of graphene-alumina hybrid reinforced copper-based composite material, described method is carried out according to the following steps:

[0065] S01: Place graphene nanosheets with a thickness of 0.1-3nm and a diameter of 1-2μm in an ultrasonic container for ultrasonic dispersion for 2 hours, and take the ultrasonically dispersed graphene and immerse it in SnCl 2 In the sensitization solution, ultrasonically disperse for 30 minutes again, take it out, filter it, and wash it with deionized water multiple times; then put the graphene after sensitization into the palladium sink solution to activate it, then ultrasonically disperse it for 30 minutes, take it out and filter it, and use The deionized water was washed several times and then used; finally, the surface of the sensitized and activated graphene particles was treated with electroless nickel plating to obtain graphene@Ni.

[0066] S02: Put Cu-0.6wt%Al (mass percentage) atomized alloy po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com