Wear-resistant hammer head of hammer crusher and preparation method thereof

A technology of hammer head and model, which is applied in the field of hammer head and its preparation, can solve the problems of complicated operation process, low bonding strength, falling blocks and fractures, etc., and achieve the effect of advanced technology, high recovery rate and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The composition of the material at the end of the hammer head is by weight percentage:

[0038] C: 2.42%, Si: 0.31%, Mn: 0.58%, Cr: 12.8%, Ce: 0.04%, V: 0.20%, P: 0.10%, S: 0.06%, and the rest is iron;

[0039] The material composition of the hammer head handle is as follows in weight percentage:

[0040] C: 0.31%, Si: 0.35%, Mn: 0.71%, Cr: 1.20%, Mo: 0.15%, P: 0.04%, S: 0.04%, and the remainder is iron.

[0041] The preparation method of described tup is:

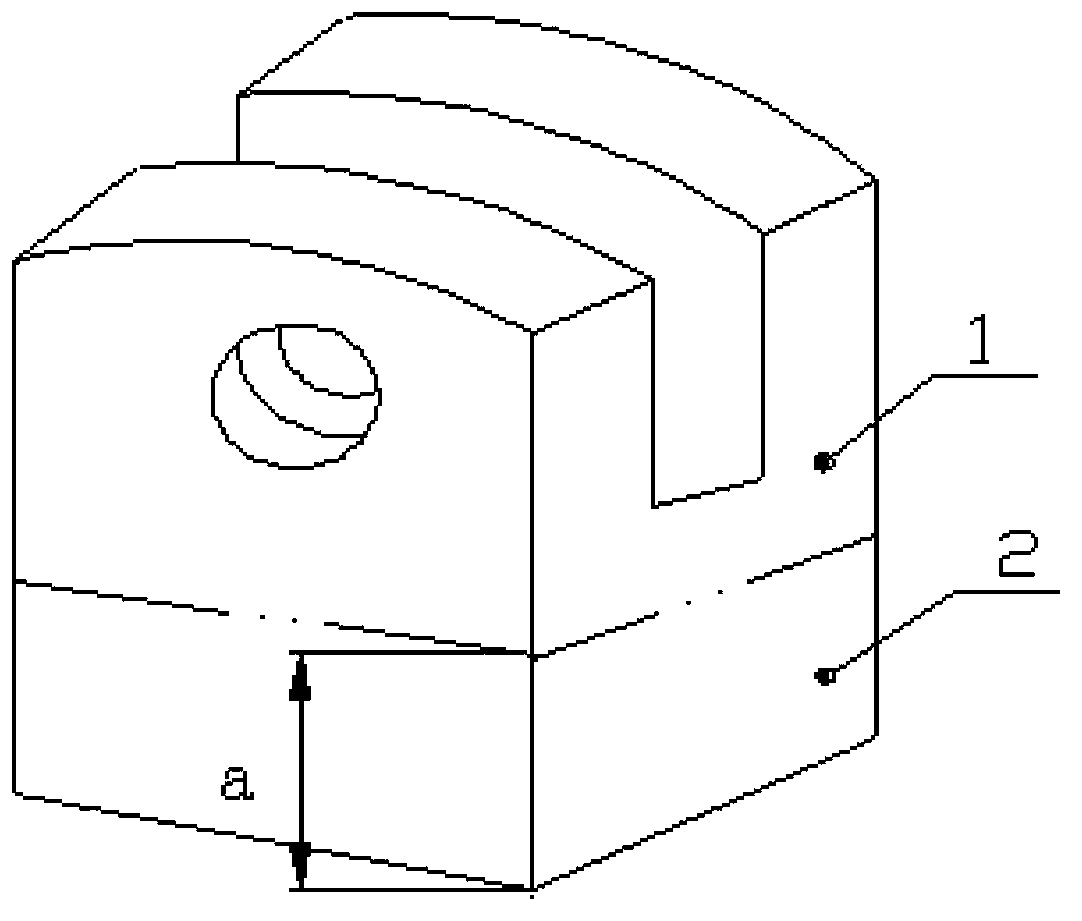

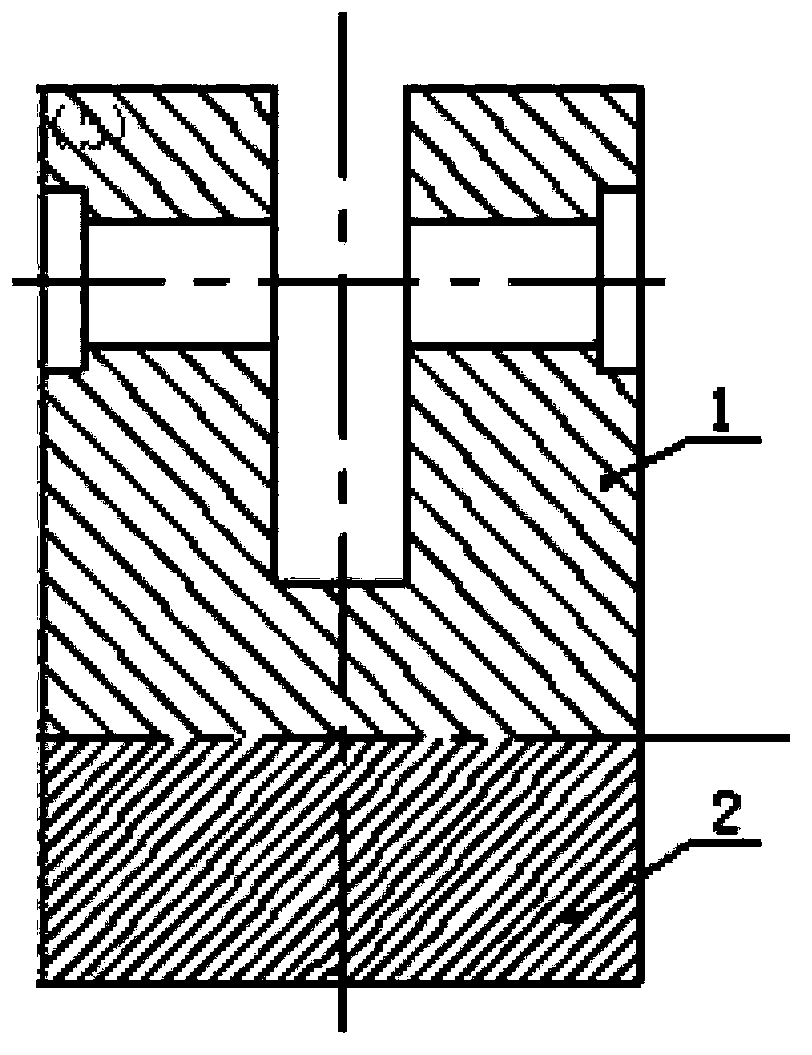

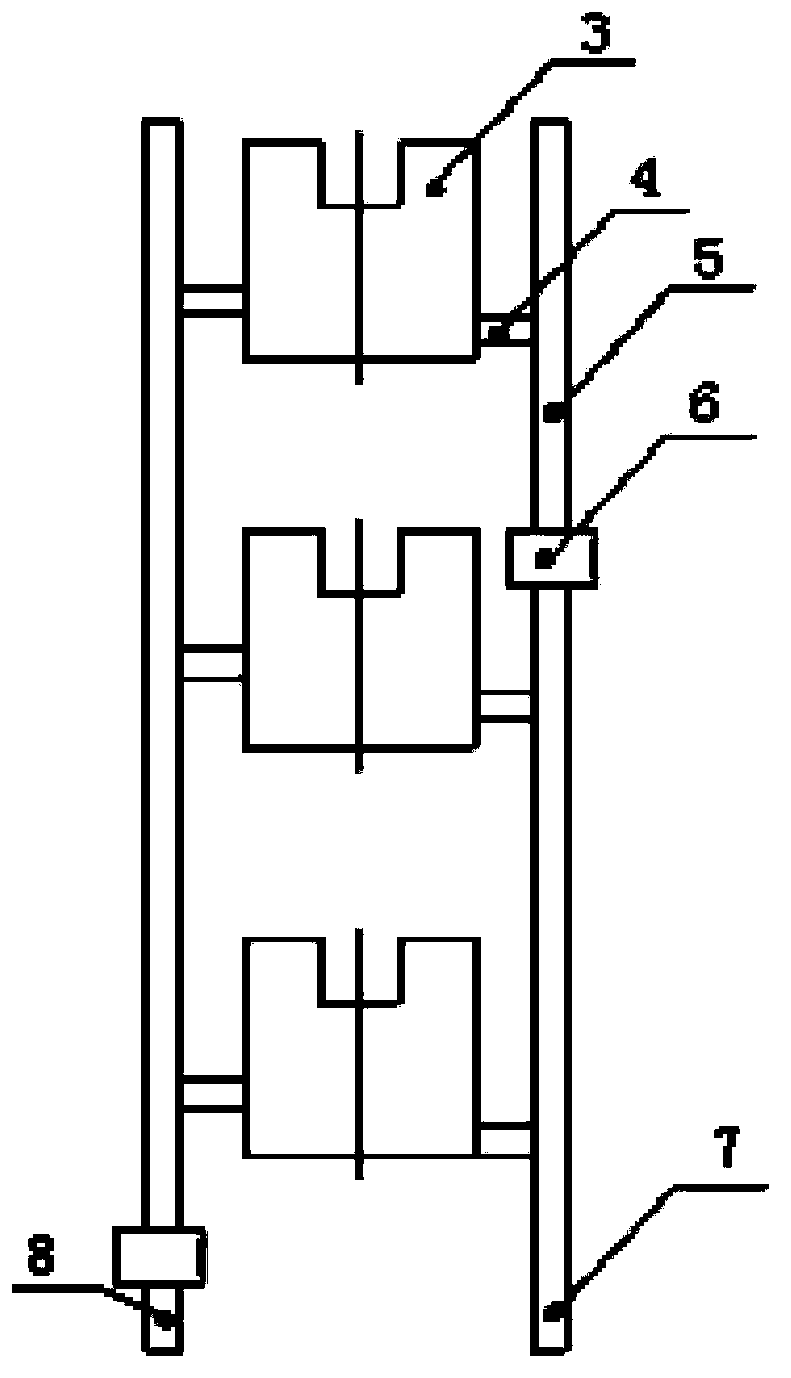

[0042] 1) Use resistance wire to cut polystyrene foam to make the hammer head model, in which the middle of the end model of the hammer head is hollow, and the surrounding wall thickness is 10mm; the foam density is 0.016g / cm 3 ;

[0043] 2) The hammerhead foam model is painted and baked,

[0044] a) Preparation of paint: paint a, the composition weight percentage is: quartz sand: particle size 200 mesh, 22%; powdery cellulose: 1.1%; commercially available ordinary white latex: 1.1%; tap water: 11%. After prepa...

Embodiment 2

[0057] The composition of the material at the end of the hammer head is by weight percentage:

[0058] C: 2.86%, Si: 0.60%, Mn: 0.78%, Cr: 13.2%, Ce: 0.04%, V: 0.10%, P: 0.10%, S: 0.06%, the rest is iron;

[0059] The material composition of the shank of the hammer head is by weight percentage:

[0060] C: 0.35%, Si: 0.78%, Mn: 1.20%, Cr: 1.30%, Mo: 0.18%, P: 0.04%, S: 0.04%, the rest is iron;

[0061] The preparation method of described tup is:

[0062] 1) Use resistance wire to cut polystyrene foam to make the hammer head model, in which the middle of the end model of the hammer head is hollow, and the surrounding wall thickness is 10mm; the foam density is 0.017g / cm 3 ;

[0063] 2) The hammerhead foam model is painted and baked,

[0064] a) Preparation of paint: paint a, the composition weight percentage is: quartz sand: particle size 240 mesh, 23%; powdered cellulose: 1.3%; commercially available ordinary white latex: 1.3%; tap water: 11%. After preparation, it is sti...

Embodiment 3

[0077] The composition of the material at the end of the hammer head is by weight percentage:

[0078] C: 2.98%, Si: 1.30%, Mn: 1.60%, Cr: 14.0%, Ce: 0.04%, V: 0.15%, P: 0.10%, S: 0.06%, and the remainder is iron;

[0079] The material composition of the shank of the hammer head is by weight percentage:

[0080] C: 0.43%, Si: 0.92%, Mn: 1.32%, Cr: 2.63%, Mo: 0.20%, P: 0.04%, S: 0.04%, and the remainder is iron.

[0081] The preparation method of described tup is:

[0082] 1) Use resistance wire to cut polystyrene foam to make the hammer head model, in which the middle of the end model of the hammer head is hollow, and the surrounding wall thickness is 10mm; the foam density is 0.017g / cm 3 ;

[0083] 2) The hammerhead foam model is painted and baked,

[0084] a) Preparation of paint: paint a, the composition weight percentage is: quartz sand: particle size 260 mesh, 24%; powdered cellulose: 1.4%; commercially available ordinary white latex: 1.4%; tap water: 13%. After prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com