Pigment layer and method of permanently scribing a substrateby means of high-energy radiation

A pigment layer, permanence technology, applied in the direction of radiation-absorbing paints, reproduction/marking methods, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

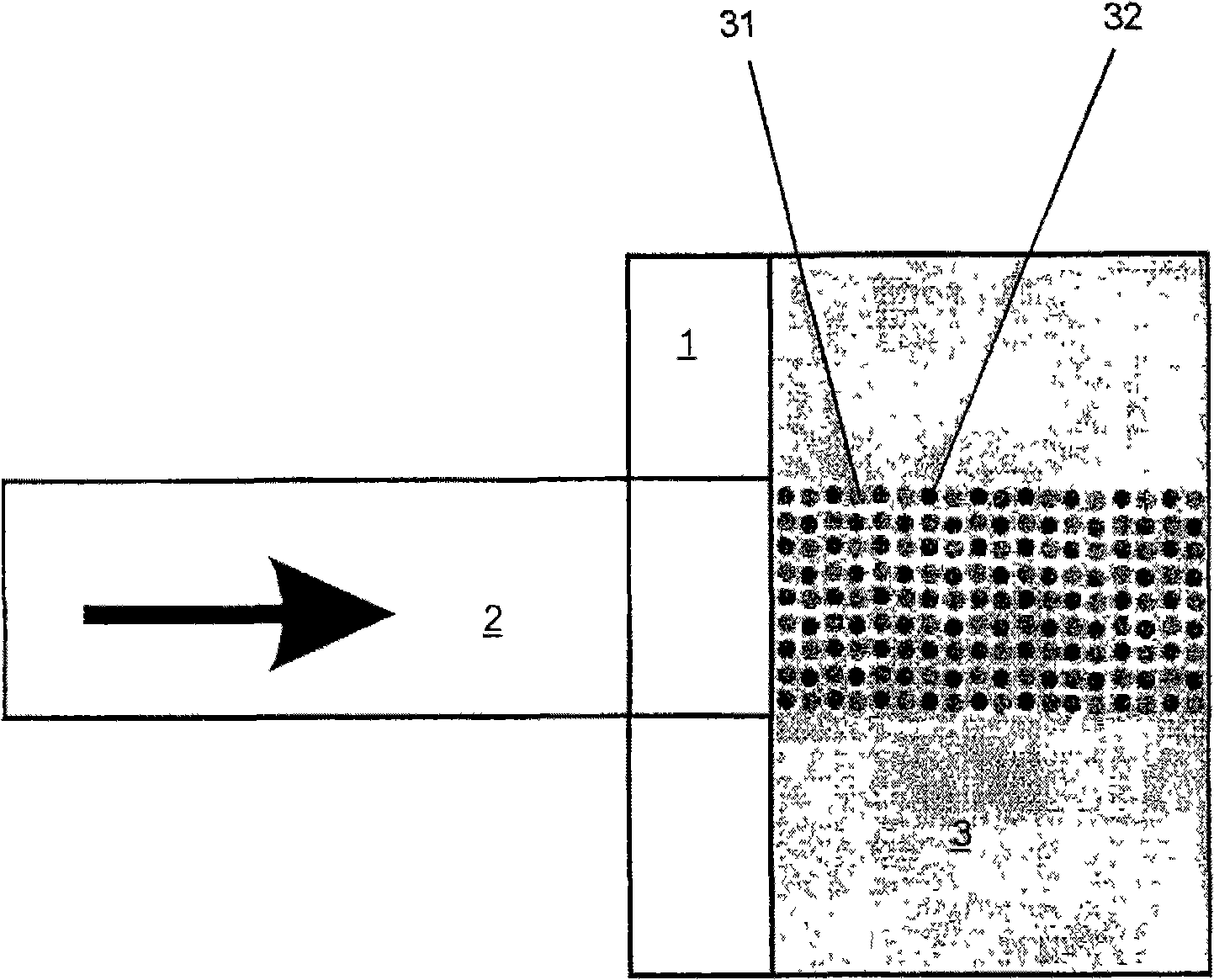

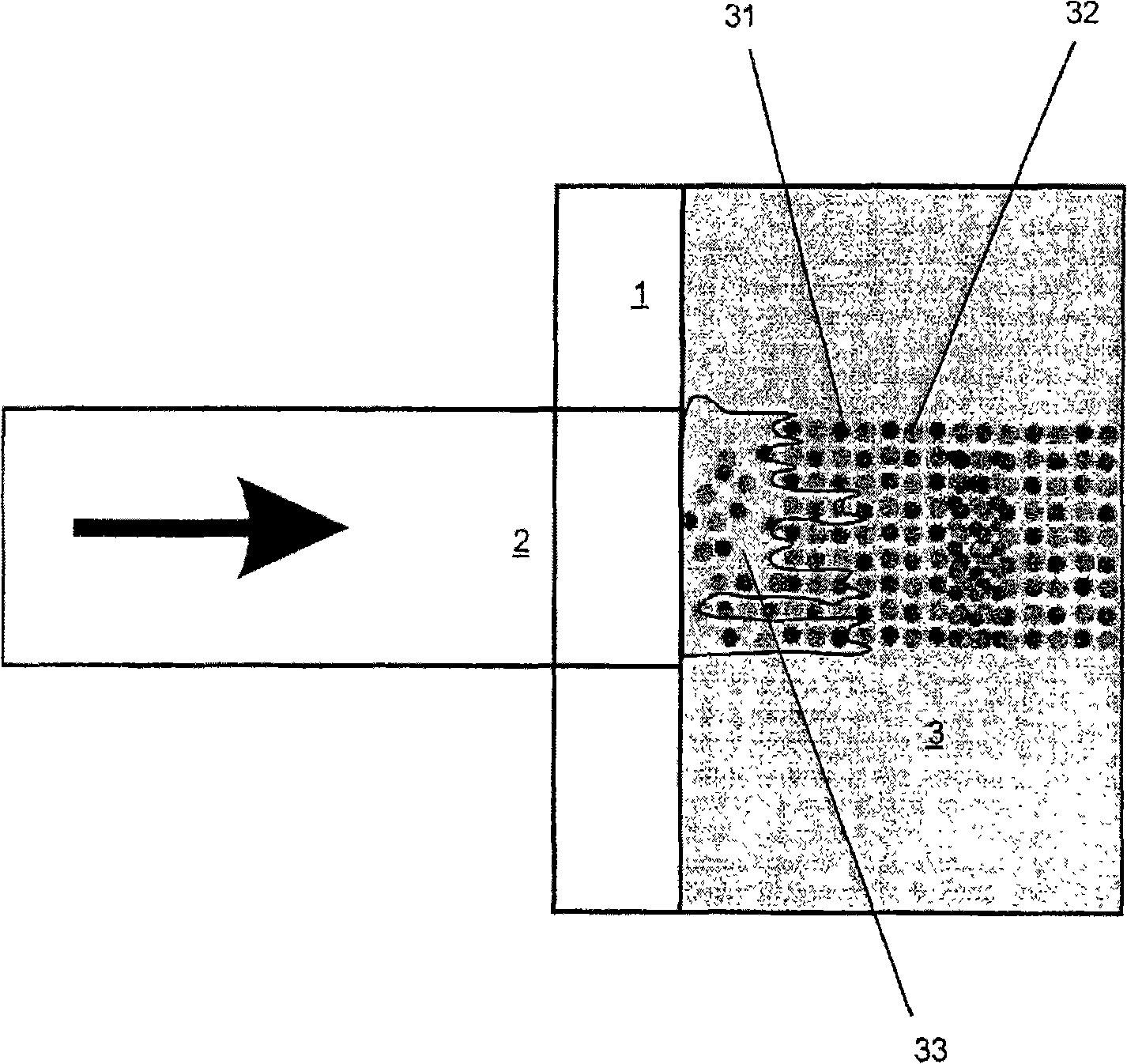

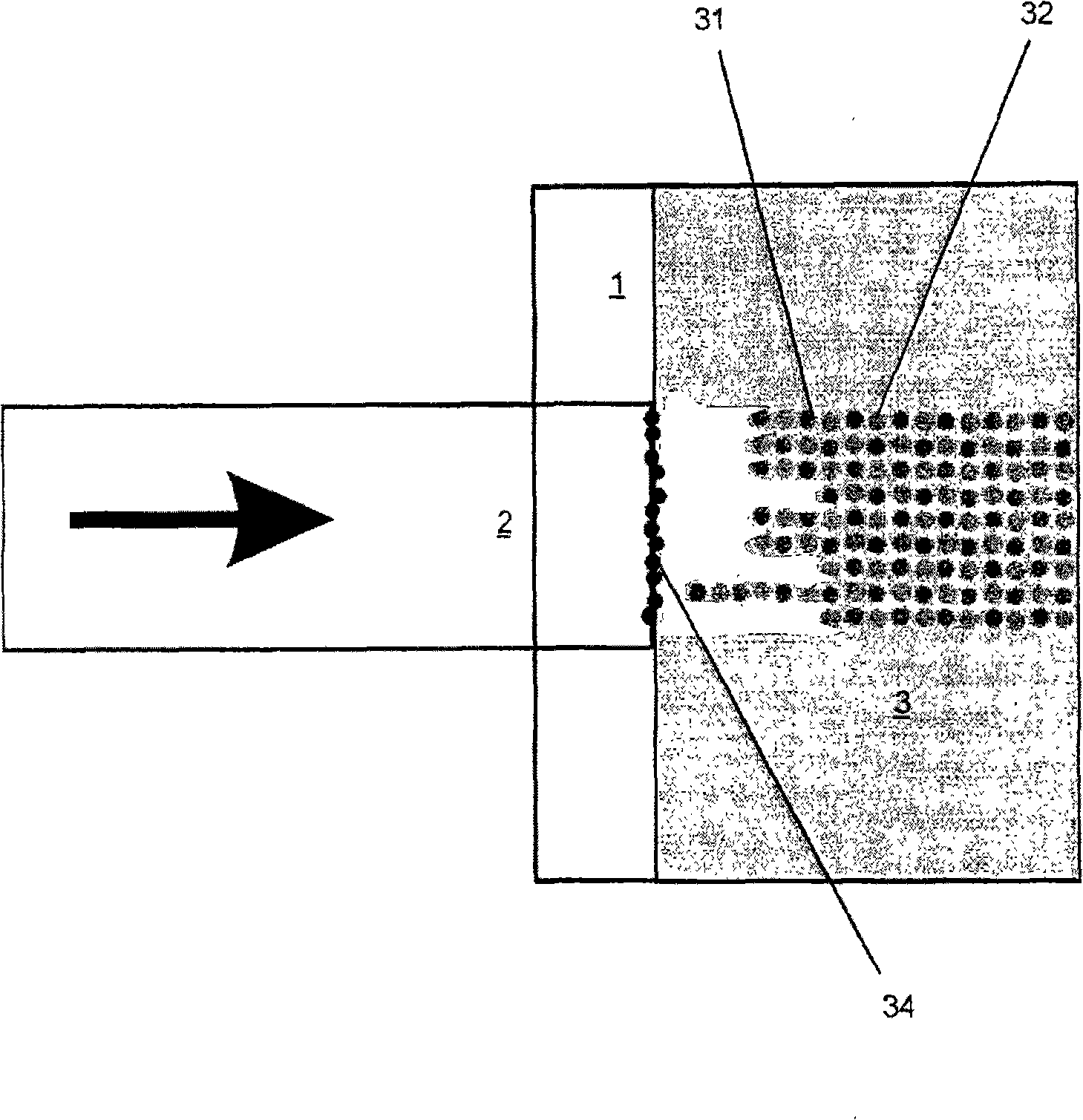

Image

Examples

Embodiment

[0107] In the following, the composition of the polymer layer is shown in more detail by way of example, without any restrictive effect:

[0108] Substrate Fraction (phr)

[0109] EB 284 85.1

[0110] HDDA 5.0

[0111] DVE 3 9.9

[0112] Carbon black 0.4

[0113] Titanium dioxide 63.2

[0114] Total 163.6

[0115] EB 284: Aliphatic, Difunctional Urethane Acrylates (Manufacturer: Cytec)

[0116] HDDA: Hexylene glycol diacrylate (manufacturer: BASF)

[0117] DVE 3: Divinyl ether (manufacturer: ISP or BASF)

[0118] Carbon black: Furnace black, particle size 56nm, surface area 45m 2 / g (Manufacturer: Evonik, Printex25)

[0119] TiO 2 : (Manufacturer: Kronos, Kronos 2160)

[0120] This composition was applied to form a layer with a thickness of 100 μm. Measurement samples of 30×50 mm were produced from the coating by punching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com