Polyurethane specular putty coating and preparation method thereof

A polyurethane and putty technology, applied in the direction of filling slurry, etc., can solve the problems of rising putty cost, high resin cost, increasing base material, etc., and achieve the effect of long production time, low cost and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

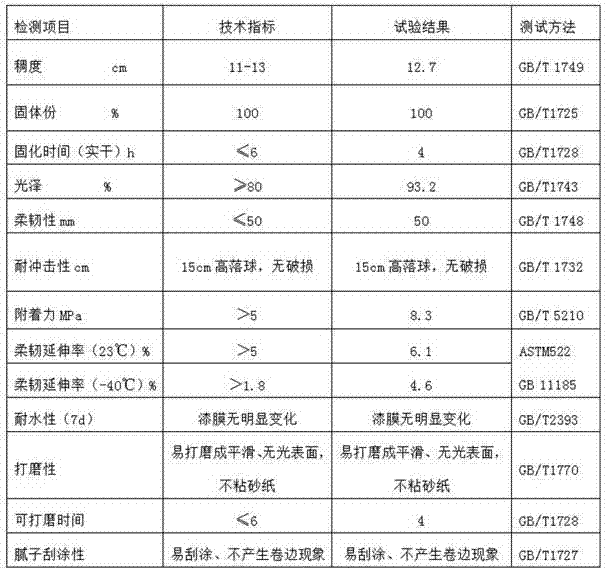

Examples

Embodiment 1

[0027] 1. Formula of polyurethane high-gloss putty coating

[0028] The polyurethane high-gloss putty paint of this embodiment, component A: component B = 8:1

[0029] Among them, A component is: polyester resin 30.0kg, wetting and dispersing agent 0.2kg, polysiloxane defoamer 0.8kg, organic bentonite anti-sedimentation agent 2.0kg, talcum powder 25.0kg, active calcium carbonate 27.0kg, weight Spar powder 5.0kg, rutile titanium dioxide 10.0kg.

[0030] B component is: diphenylmethane diisocyanate (MDI) curing agent 100kg.

[0031] 2. Preparation method of polyurethane high-gloss putty coating

[0032] The preparation method of the present embodiment polyurethane high-gloss putty coating comprises the following steps:

[0033] ①Preparation of component A: Weigh 30.0kg of 1150 polyester resin produced by Germany Bayer Co., Ltd. and add it to the high-speed dispersing axe. Add 0.2kg of wetting and dispersing agent, 0.8kg of polysiloxane defoamer, organic bentonite anti-foaming...

Embodiment 2

[0042] 1. Formula of polyurethane high-gloss putty coating

[0043] The polyurethane high-gloss putty paint of this embodiment, component A: component B = 6:1

[0044]Among them, A component is: polyester resin 35.0kg, wetting and dispersing agent 0.4kg, polysiloxane defoamer 0.6kg, polyamide wax anti-settling agent 1.0kg, talcum powder 30.0kg, activated calcium carbonate 17.0kg, Barite powder 10.0kg, rutile titanium dioxide 6.0kg.

[0045] B component is: diphenylmethane diisocyanate (MDI) curing agent 100kg.

[0046] 2. Preparation method of polyurethane high-gloss putty coating

[0047] The preparation method of the present embodiment polyurethane high-gloss putty coating comprises the following steps:

[0048] ①Preparation of component A: Weigh 35.0 kg of 1150 polyester resin produced by Bayer Co., Ltd. in Germany and add it to the high-speed dispersing axe. Add 0.4 kg of wetting and dispersing agent, 0.6 kg of defoaming agent, and 1.0 kg of polyamide wax anti-settling ...

Embodiment 3

[0057] 1. Formula of polyurethane high-gloss putty coating

[0058] The polyurethane high-gloss putty paint of this embodiment, component A: component B = 4:1

[0059] Among them, A component is: polyester resin 40.0kg, wetting and dispersing agent 0.3kg, polysiloxane defoamer 0.7kg, organic bentonite anti-sedimentation agent 1.5kg, talcum powder 20.0kg, active calcium carbonate 22.0kg, weight Spar powder 7.5kg, rutile titanium dioxide 8.0kg.

[0060] B component is: diphenylmethane diisocyanate (MDI) curing agent 100kg.

[0061] 2. Preparation method of polyurethane high-gloss putty coating

[0062] The preparation method of the present embodiment polyurethane high-gloss putty coating comprises the following steps:

[0063] ①Preparation of component A: Weigh 40.0 kg of 1150 polyester resin produced by Bayer Co., Ltd. in Germany and add it to the high-speed dispersing axe. Add 0.3 kg of wetting and dispersing agent, 0.7 kg of polysiloxane defoamer, and organic bentonite ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com