Super-hydrophobic wear-resistant graphene composite coating and solar collector tube using the same

A solar collector tube and graphene composite technology, which can be used in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc. The heat pipe glass is not resistant to sand and dust impact, and the transmittance of the glass outer tube is attenuated, so as to improve the light-to-heat conversion efficiency, achieve long-term stable operation, and reduce the cleaning workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

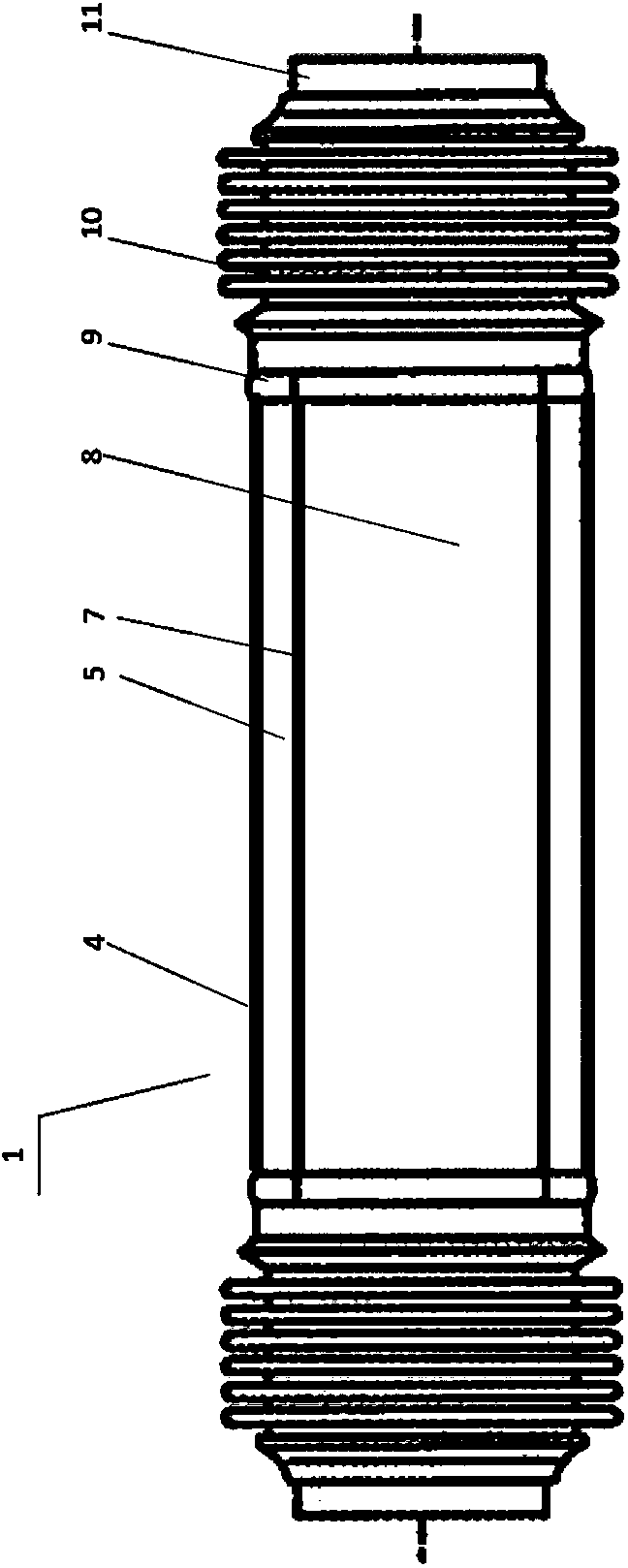

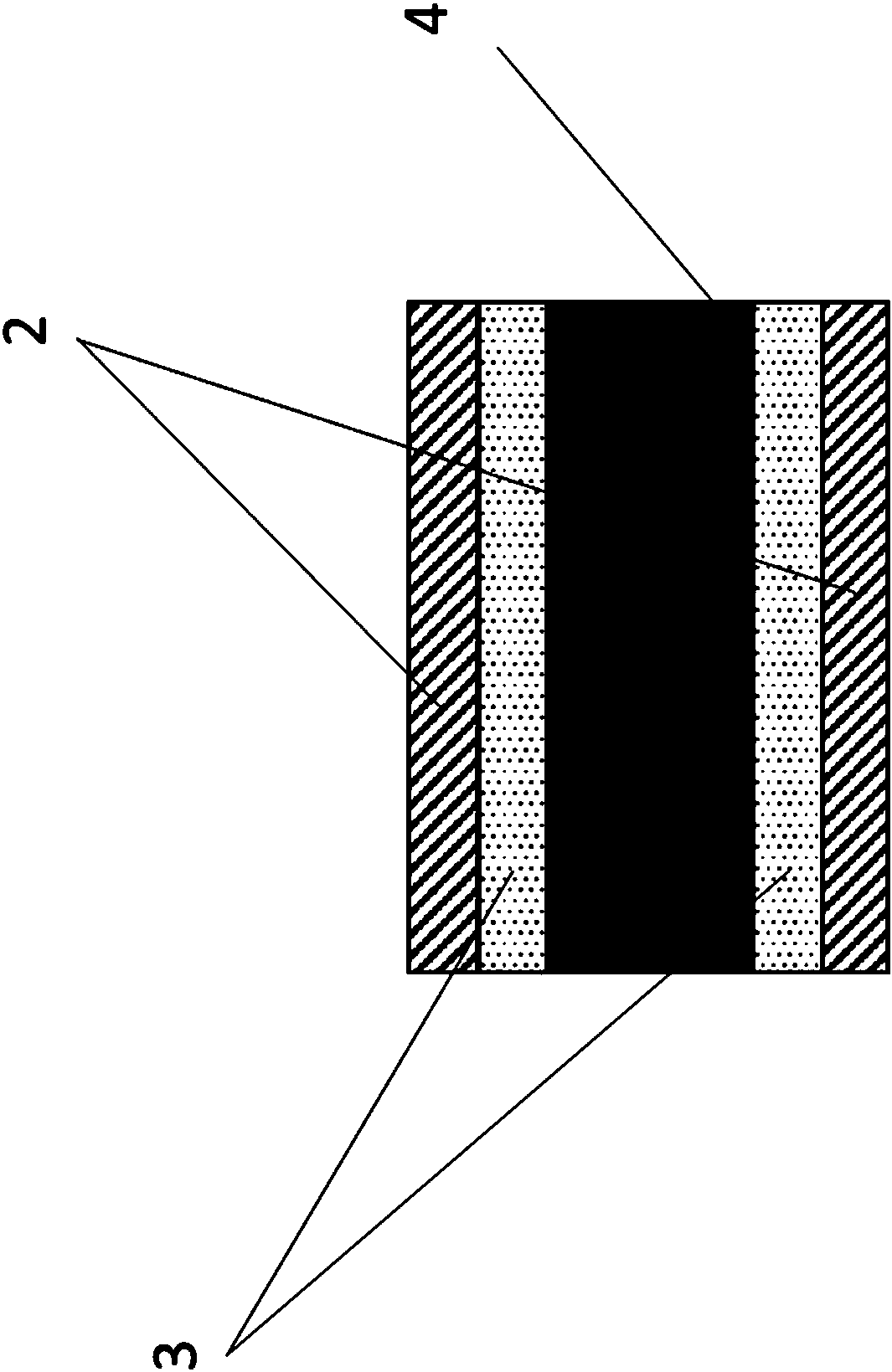

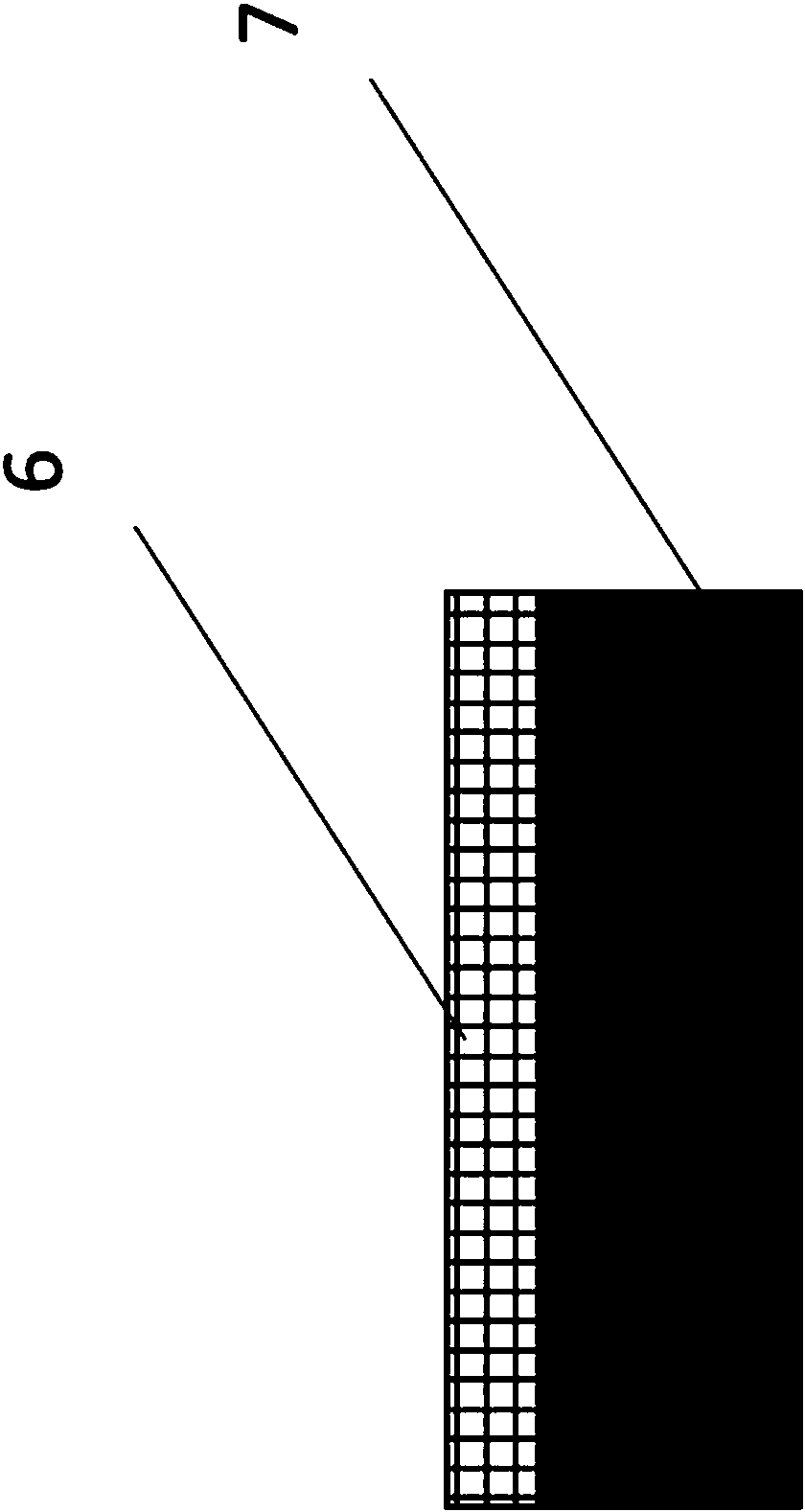

[0031] The invention protects a composite coating of graphene oxide and photocatalytically active nano-particle titanium dioxide, a superhydrophobic and wear-resistant graphene composite coating prepared by using the composite coating, and a solar heat collection tube coated with the coating.

[0032] The method for making graphene oxide and photocatalytically active nano particle titanium dioxide composite coating comprises the following steps:

[0033] a. Prepare graphene oxide dispersion: prepare graphene oxide dispersion in ethanol solution or deionized water, the concentration of graphene oxide is 0.05-0.5mg / ml, prepare graphene oxide dispersion after ultrasonic oscillation;

[0034] b. Configure titanium dioxide dispersion: prepare titanium dioxide dispersion in ethanol solution or deionized water, the concentration of titanium dioxide is 0.05-0.5mg / ml, prepare titanium dioxide dispersion after ultrasonic oscillation;

[0035] c. blend the titanium dioxide dispersion wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com