Conductive abradable seal coating material and preparation method thereof

A technology of sealing coatings and conductive fillers, which is applied in the direction of conductive coatings and coatings, can solve the problems that cannot meet the requirements of EDM, do not have conductivity, and the coating is easy to crack, so as to improve the scratch performance and conductivity Excellent performance, low cost, and less damage to the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

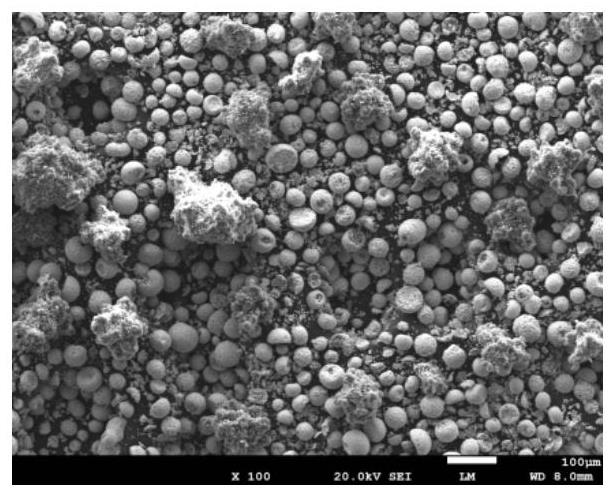

Image

Examples

Embodiment 1

[0045] Typical turbine outer ring components, the matrix material is infiltrated SiCf / SiC composite material. Use acetone to ultrasonically clean the surface of the components, dry the surface with compressed air, and put it into a resistance furnace for drying.

[0046] The machined surface is sandblasted with SiC sand grains with multi-water chestnut structure. The SiC sand grain size is 100 mesh, the working gas pressure is 0.3MPa, and the surface roughness after sandblasting is Ra3.2μm.

[0047] The silicon layer is sprayed on the surface of the component by vacuum plasma technology, with argon and hydrogen as the working gas, the control spray gun power is 40kW, the flow rate of argon gas is 55L / min, the flow rate of hydrogen gas is 10L / min, the spraying distance is 300mm, and the pressure of the vacuum chamber is 200Pa. After spraying, the thickness of the coating is 0.06mm, the bonding strength of the coating is 26MPa, the porosity of the coating is 0.8%, and the oxygen...

Embodiment 2

[0059] Typical turbine outer ring components, the matrix material is SiCf / SiC composite material of CVI process. Use acetone to ultrasonically clean the surface of the components, dry the surface with compressed air, and put it into a resistance furnace for drying.

[0060] The abradable sealing surface layer powder material is composed of lutetium silicate, molybdenum, molybdenum silicide and polyester, wherein the weight percentage is: dilute lutetium silicate 65%, nanometer molybdenum 25%, molybdenum silicide 2.0%, polyester: 8.0%. The preparation process of the abradable sealing surface layer powder material specifically includes the following steps:

[0061] Slurry preparation: mix lutetium silicate powder with a particle size of 2 μm, pure molybdenum powder with a particle size of 100 nm, and molybdenum silicide powder with a particle size of 1 μm in proportion, add deionized water for ball milling according to the powder volume content of 30%, and add the total weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com