Preparation method of organic thin-film field effect transistor

A field effect transistor and organic thin film technology, applied in the field of semiconductor field effect transistor device preparation, can solve the problems of affecting device performance, high cost of printing equipment, extremely demanding physical and chemical properties, etc., to achieve strong water and oxygen resistance, environmental protection The effect of loose, simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

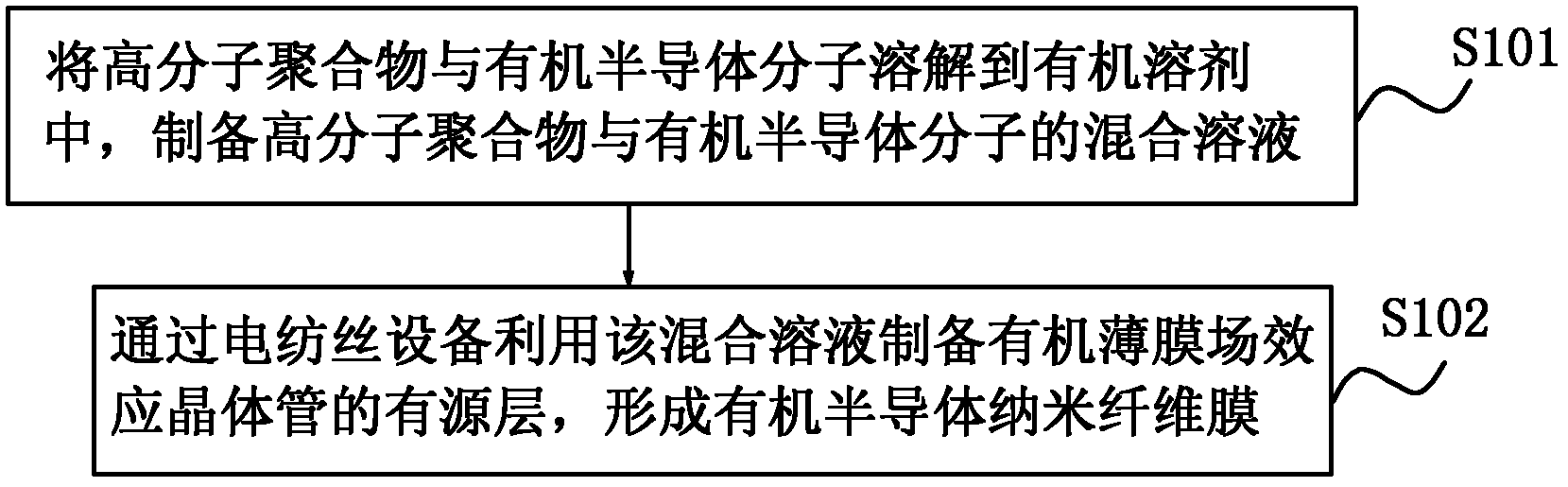

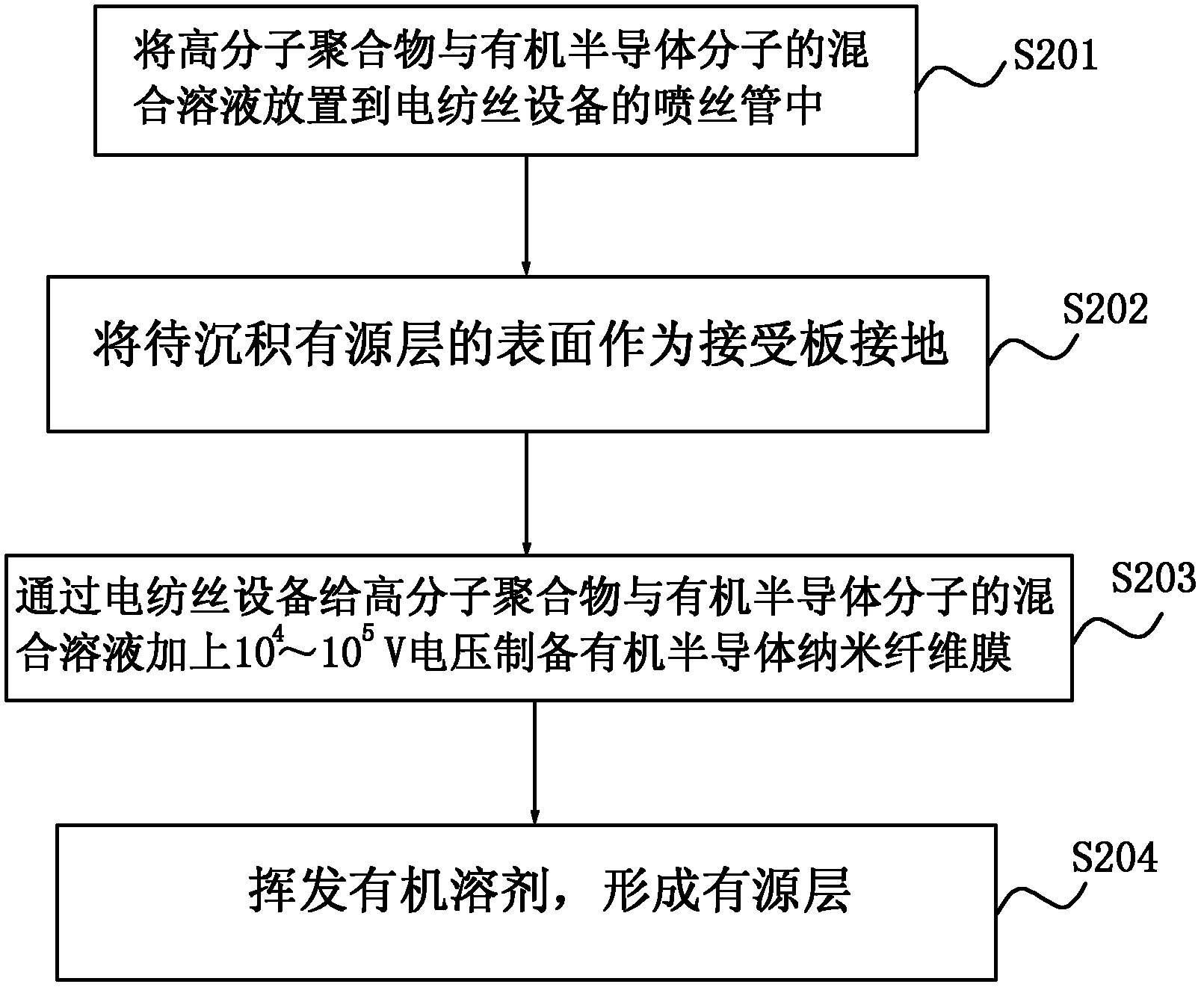

[0034] see figure 1 , figure 2 , Figure 5 with Figure 7 ,Such as figure 1 As shown, the method for preparing an organic thin film field effect transistor provided in this embodiment includes:

[0035] S101, dissolving the high molecular polymer and the organic semiconductor molecule into an organic solvent to prepare a mixed solution of the high molecular polymer and the organic semiconductor molecule;

[0036] S102, using the mixed solution to prepare an active layer of an organic thin film field effect transistor through an electrospinning device to form an organic semiconductor nanofiber film.

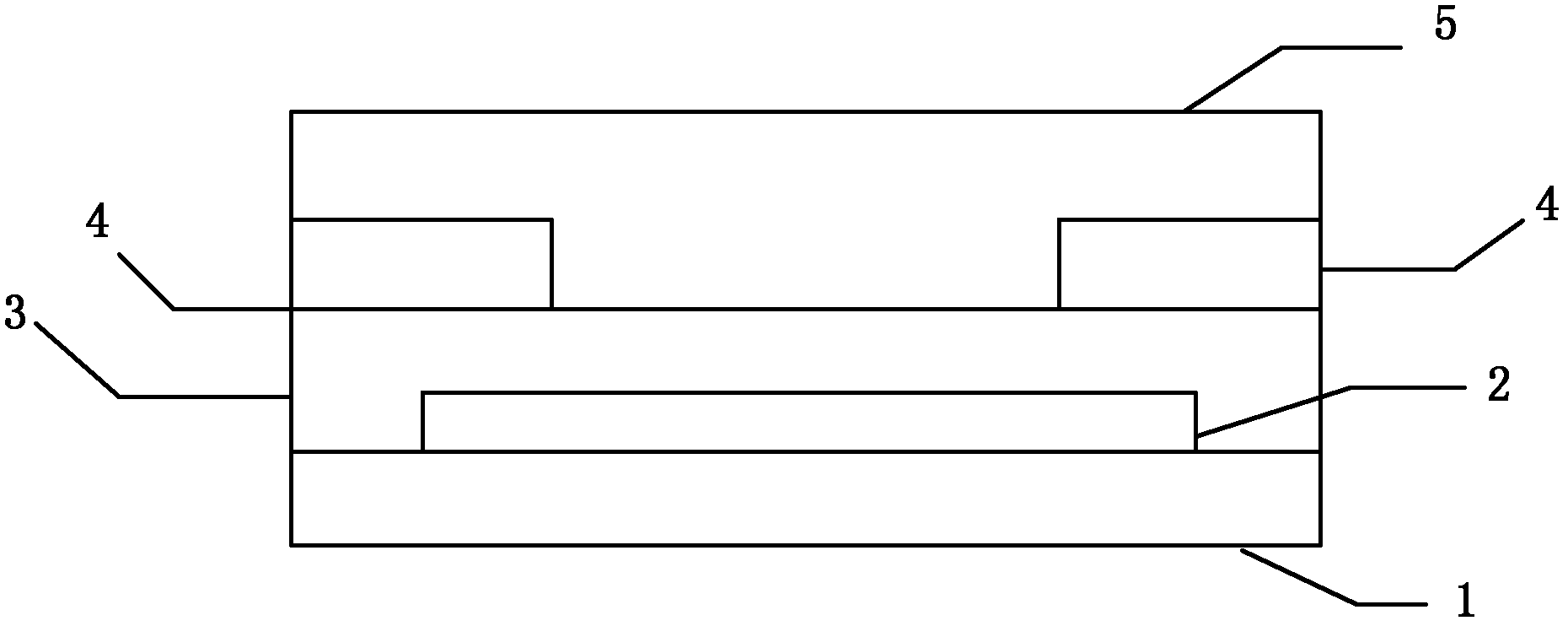

[0037] Among them, such as Figure 5 As shown, the field effect transistor of this embodiment includes a substrate 1 , a gate electrode 2 , an insulating layer 3 , source and drain electrodes 4 and an active layer 5 . Wherein, the substrate 1 is a glass material, and the mixed solution is prepared by stirring the mixed solution of the polymer and the organic semiconductor m...

Embodiment 2

[0048] see figure 1 , figure 2 , Figure 4 with Figure 7 ,Such as figure 1 As shown, the method for preparing an organic thin film field effect transistor provided in this embodiment includes:

[0049] S101, dissolving the high molecular polymer and the organic semiconductor molecule into an organic solvent to prepare a mixed solution of the high molecular polymer and the organic semiconductor molecule;

[0050]S102, using the mixed solution to prepare an active layer of an organic thin film field effect transistor through an electrospinning device to form an organic semiconductor nanofiber film.

[0051] Among them, such as Figure 4 As shown, the field effect transistor of this embodiment includes a substrate 1 , a gate electrode 2 , an insulating layer 3 , source and drain electrodes 4 and an active layer 5 . Wherein, the substrate 1 is a ceramic material. In this embodiment, the method for preparing the mixed solution is to stir the mixed solution of the high molec...

Embodiment 3

[0062] see figure 1 , 2 , 5, 7, such as figure 1 As shown, the method for preparing an organic thin film field effect transistor provided in this embodiment includes:

[0063] S101, dissolving the high molecular polymer and the organic semiconductor molecule into an organic solvent to prepare a mixed solution of the high molecular polymer and the organic semiconductor molecule;

[0064] S102, using the mixed solution to prepare an active layer of an organic thin film field effect transistor through an electrospinning device to form an organic semiconductor nanofiber film.

[0065] Among them, such as Figure 5 As shown, the field effect transistor of this embodiment includes a substrate 1 , a gate electrode 2 , an insulating layer 3 , source and drain electrodes 4 and an active layer 5 . Wherein, the substrate 1 is made of silicon. In this embodiment, the method of preparing the mixed solution is to stir the mixed solution of the high molecular polymer and the organic semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com