All-graphene family flexible organic field effect tube and manufacturing method thereof

A graphene and organic field technology, which is applied in the direction of graphene, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of poor device stability, high requirements for production equipment and process control, and high energy consumption, and achieve the goal of production equipment The effect of low requirements, stable electrical performance, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments and with reference to the accompanying drawings.

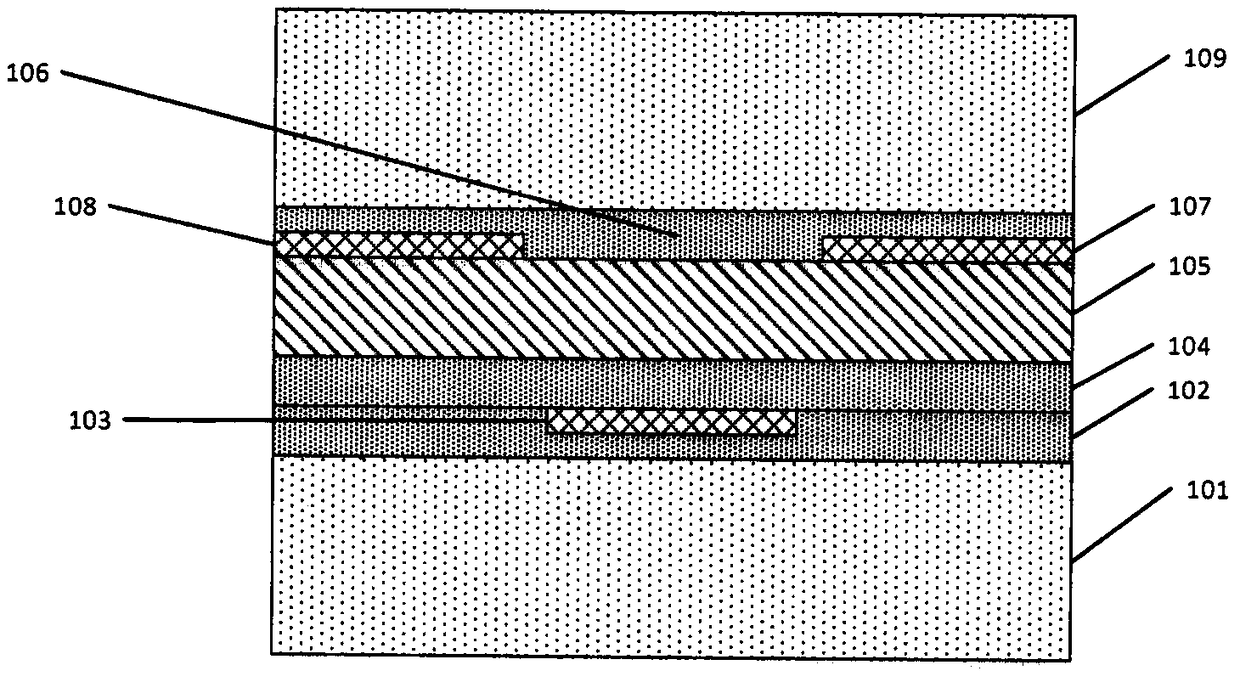

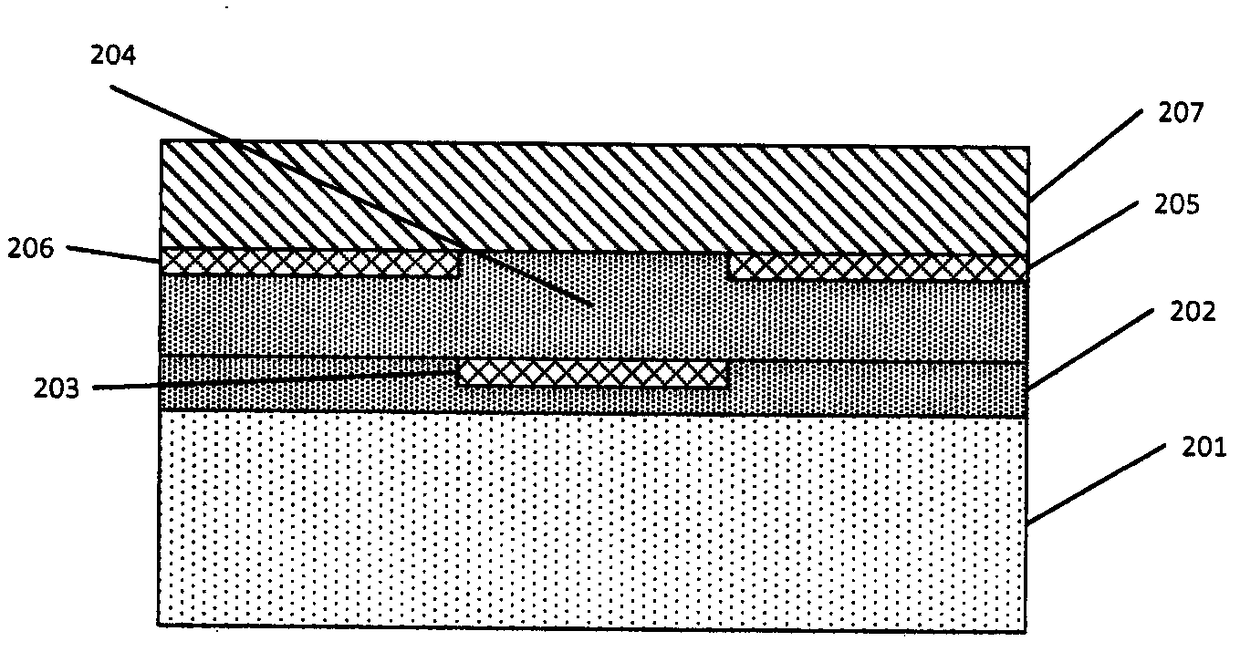

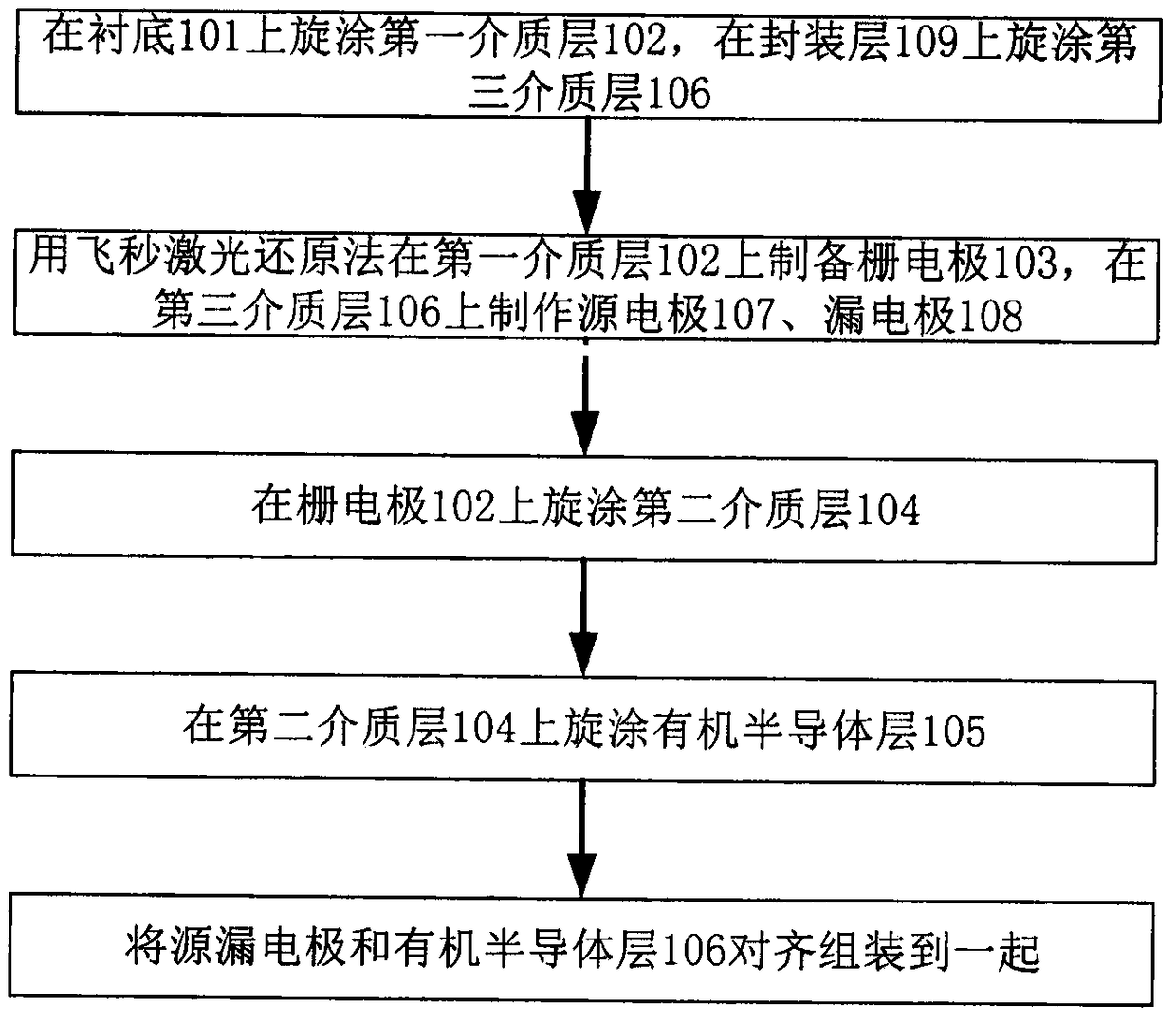

[0046] The implementation scheme of the field effect transistor with the bottom gate top contact structure is as follows:

[0047] step 1

[0048] 1.1 as Figure 6-1 and 6-2 , select PI with a thickness of 90 μm, scrub the PI with detergent powder and cut it into 2cm×2.5cm, and then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes respectively.

[0049] 1.2 After the nitrogen gas is blown dry, the surface of the PI is treated with oxygen plasma to make the surface hydrophilic, and the preparation of the substrate 101 and the encapsulation layer 109 is completed.

[0050] step 2

[0051] 2.1 Weigh 30mg of purified graphene oxide powder with an electronic scale, weigh 60ml of ethanol with a measuring cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com