Ampoule bottle neck mark opening equipment for pharmacy department

A technology for ampoules and bottle necks, which is applied in the field of notching equipment, can solve problems such as low safety performance, crushing, infection, etc., achieve good results and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

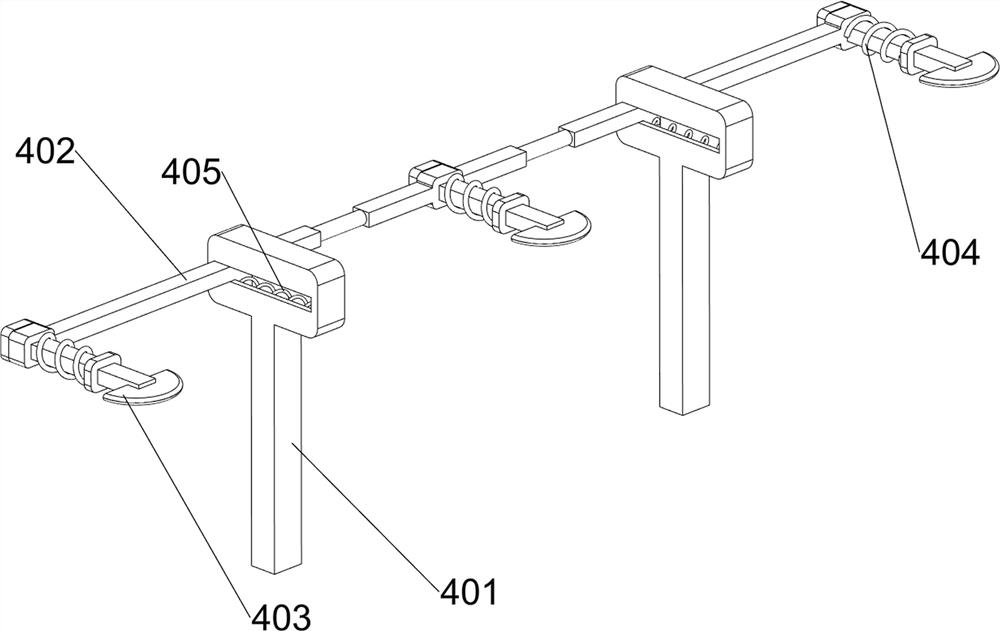

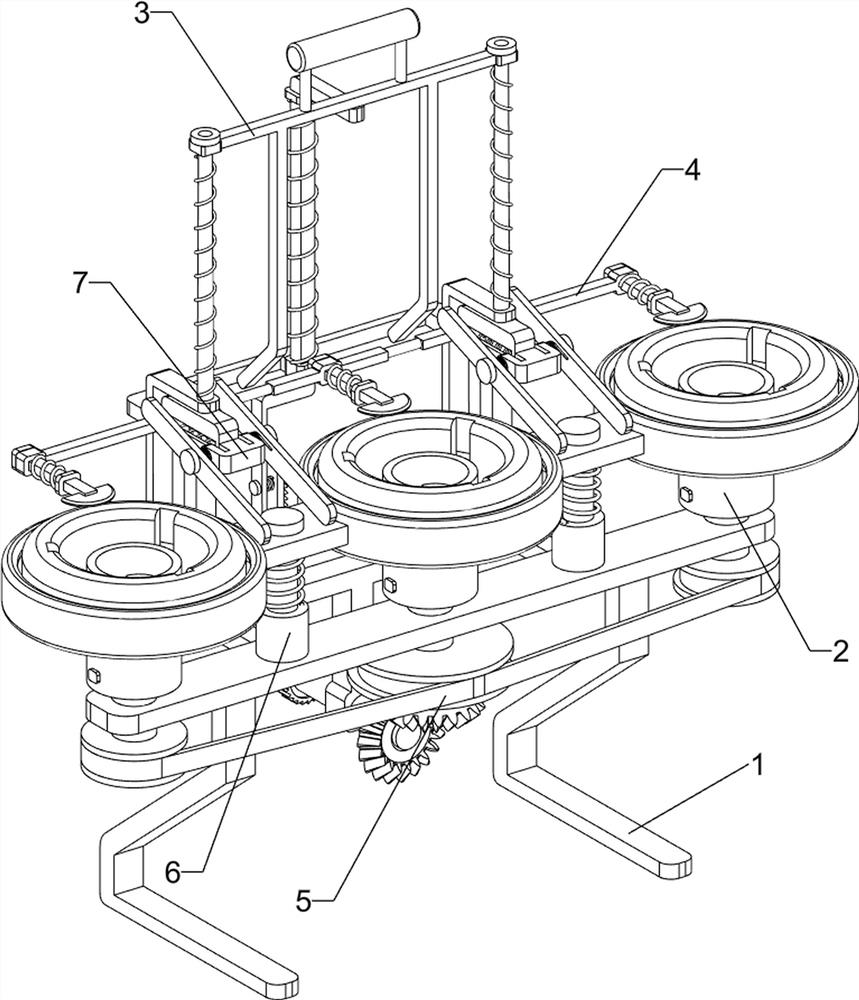

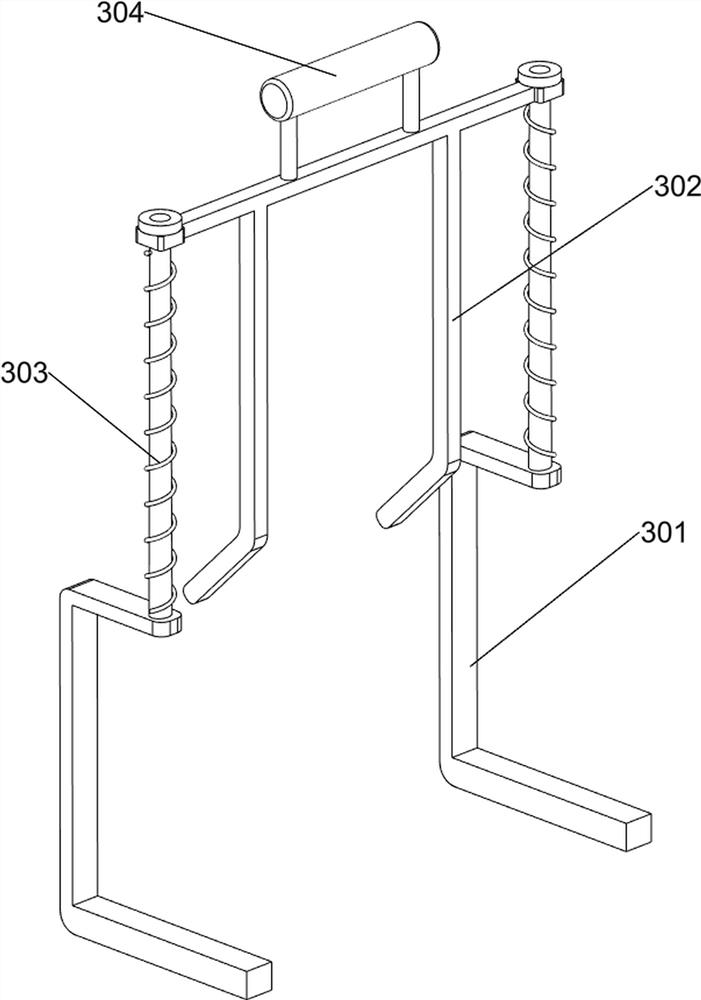

[0029] A pharmaceutical department with an ampoule bottleneck binding equipment, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, including the support frame 1, the placement assembly 2, the pressing assembly 3 and the scratch assembly 4, and the upper portion of the support frame 1 is provided, and the upper rear side of the support frame 1 is provided with a pressing assembly 3, and the pressing assembly 3 is provided. Scratch assembly 4.

[0030] The placement assembly 2 includes a first rotating shaft 201, a placing frame 202, a restricted block 203, and a first spring 204, and the upper uniform spacing of the support frame 1 is provided with three first rotating shaft 201, and the first rotation shaft 201 is provided. There is a placement frame 202, and the lower portion of the placing frame 202 is slidably equipped with a limit bit block 203, and the first spring 204 is connected between the same side limit block 203 and the placed frame 202, and the ...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 6 , Figure 7 with Figure 8 As shown, there is also a drive assembly 5, the drive assembly 5 includes a guide block 501, a second slider 502, a fifth spring 503, a ratcut strip 504, a sixth spring 505, a second support block 506, a second rotating shaft. 507, the ratchet 508, the cone gear 509, the drive wheel 510 and the belt 511, and there is a guide block 501 between the upper rear side of the upper portion of the first support rod 301, and the guide block 501 is slidably equipped with a second slider 502, a second slider. 502 is mounted between the first embossing rod 302, and the second slider 502 is connected between the guide block 501, and the fifth spring 503 is in the second slider 502, the second slider 502 lower right The side sliding equipped with a ratcinous strip 504, and a sixth spring 505 is connected between the second slider 502, and the sixth spring 505 is in the spine strip 504, the lower side of the first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com