Bearing inner ring and preparation process thereof as well as self-lubricating joint bearing

A bearing inner ring and preparation technology, which is applied to bearing components, shafts and bearings, metal material coating technology, etc., can solve the problems of accelerated self-lubricating liner wear speed, weak anti-wear ability, insufficient service life, etc., to achieve The effect of improving service life, reducing wear speed, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

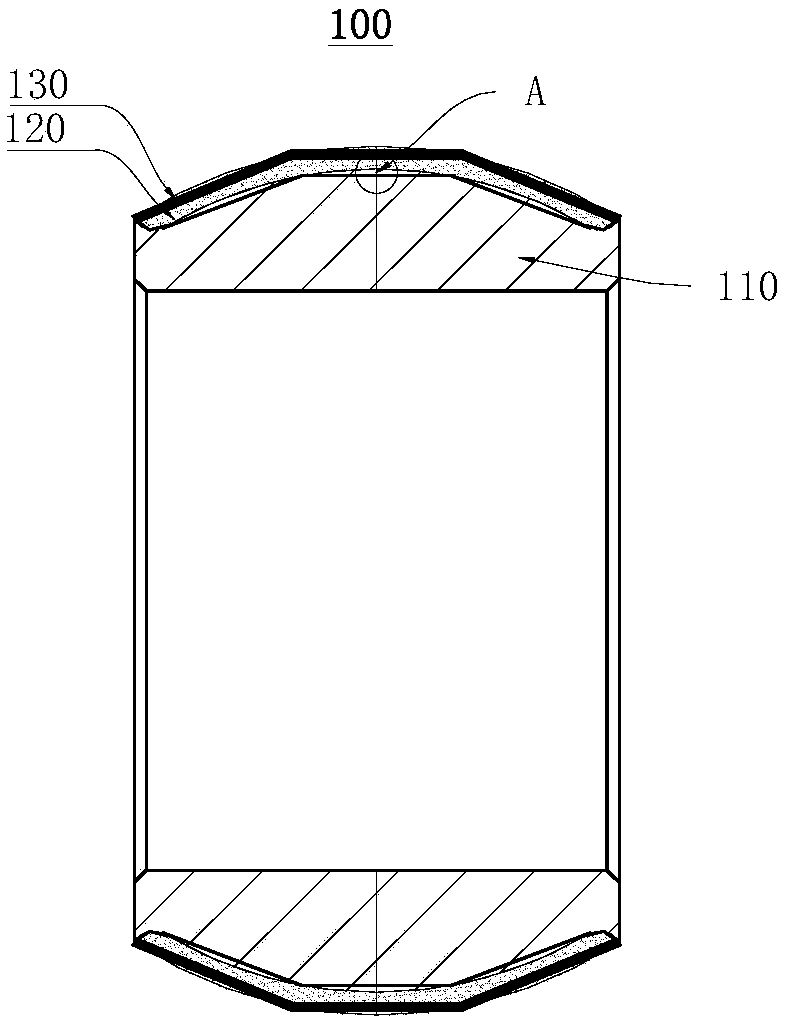

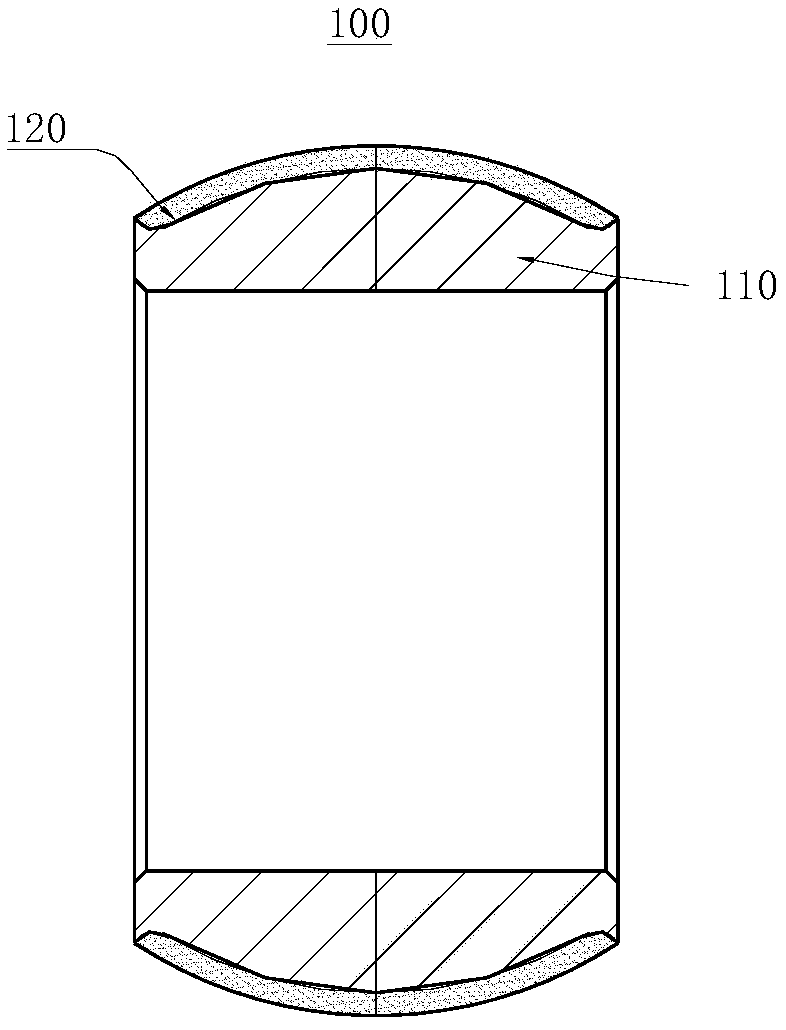

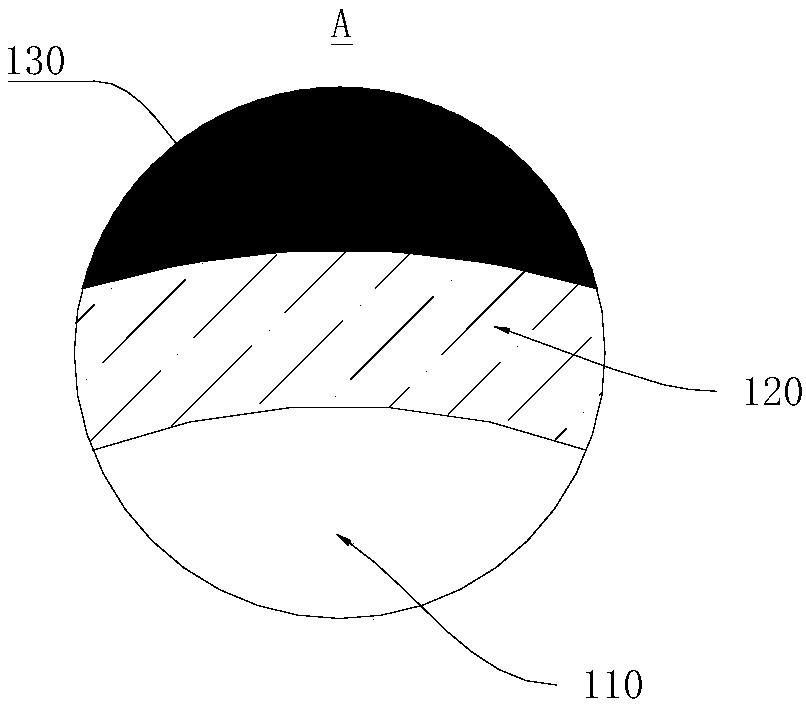

[0044] The present invention provides a preparation process for a bearing inner ring 100, which includes preparing a nitrided layer 120 and preparing a coating layer 130:

[0045] 1. Preparation of nitrided layer 120

[0046] A nitriding layer 120 with a thickness of 100-200 μm is prepared on the surface of the bearing inner ring matrix 110 by vacuum plasma nitriding method. Grinding and polishing the nitrided layer 120 of the bearing inner ring 100 to make the Ra of the inner spherical surface less than or equal to 0.08. The size and surface roughness of the inner ring meet the requirements through grinding, polishing and other processes.

[0047] 2. Prepare coating layer 130

[0048] The coating layer 130 is prepared on the surface of the nitrided layer 120 by vacuum magnetron sputtering.

[0049] see Figure 4 , the present invention also provides a self-lubricating joint bearing, which includes a bearing outer ring 200, a self-lubricating liner 300 and the above-mentio...

Embodiment 1

[0055] The embodiment of the present invention provides a bearing inner ring 100 and its preparation process and a self-lubricating joint bearing.

[0056] 1. Preparation of nitrided layer 120

[0057] A nitriding layer 120 with a thickness of 150 μm is prepared on the surface of the bearing inner ring matrix 110 by vacuum plasma nitriding method. The nitrided layer 120 of the bearing inner ring 100 is ground and polished.

[0058] 2. Prepare coating layer 130

[0059] A titanium carbonitride coating is prepared on the surface of the nitrided layer 120 by vacuum magnetron sputtering.

[0060] The bearing outer ring 200, the bearing inner ring 100 and the polytetrafluoroethylene fabric liner are assembled into a joint bearing.

Embodiment 2

[0062] The embodiment of the present invention provides a bearing inner ring 100 and its preparation process and a self-lubricating joint bearing.

[0063] 1. Preparation of nitrided layer 120

[0064] A nitriding layer 120 with a thickness of 100 μm is prepared on the surface of the bearing inner ring matrix 110 by vacuum plasma nitriding method. The nitrided layer 120 of the bearing inner ring 100 is ground and polished.

[0065] 2. Prepare coating layer 130

[0066] A titanium carbonitride coating is prepared on the surface of the nitrided layer 120 by vacuum magnetron sputtering.

[0067] The bearing outer ring 200, the bearing inner ring 100 and the polytetrafluoroethylene fabric liner are assembled into a joint bearing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com