Low odor high dispersion scratch resistant additive masterbatch and preparation method thereof

A high-dispersion and scratch-resistant technology, which is applied in the field of scratch-resistant additive masterbatch and its preparation, can solve the problems of affecting automobiles, poor product odor, and affecting applications, and achieve the effect of improving dispersibility and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation

[0019] Below in conjunction with embodiment, the present invention is described in further detail.

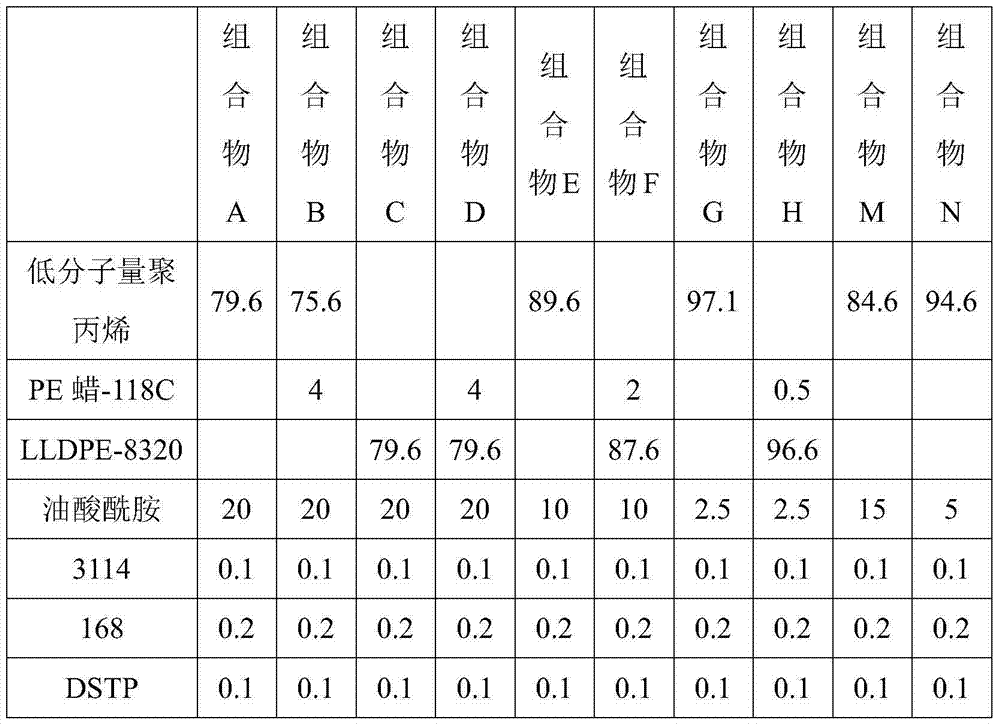

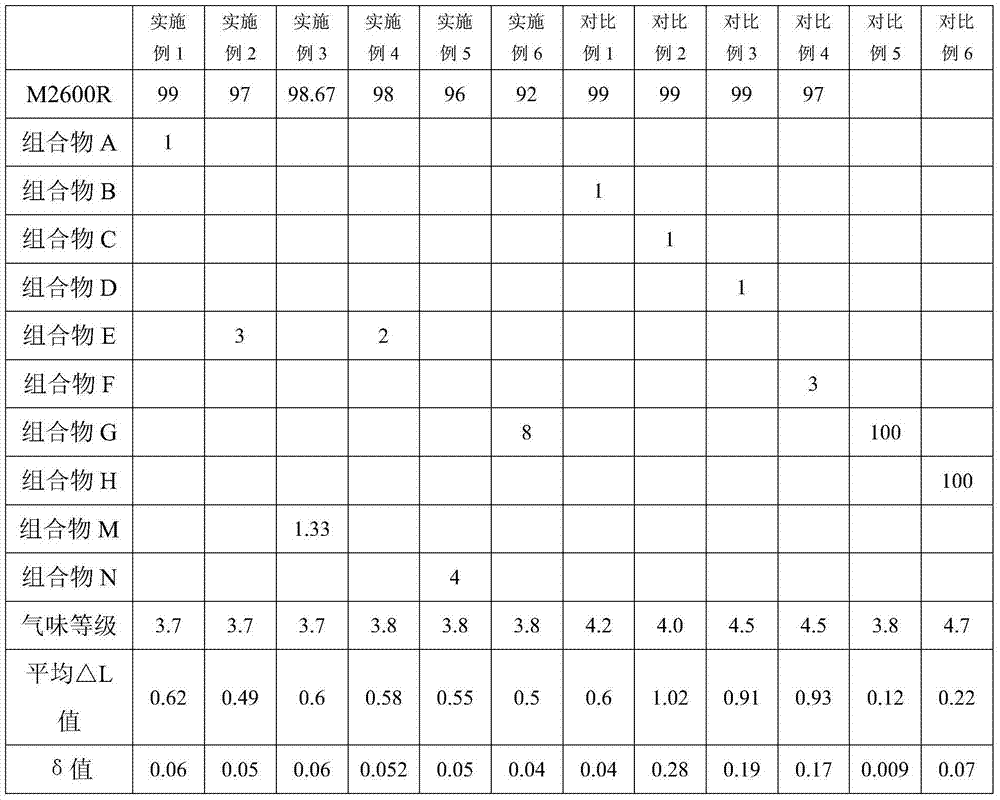

[0020] In the composite material formula of the embodiment and the comparative example, the polypropylene is a copolymerized polypropylene produced by Shanghai Petrochemical Co., Ltd., the trade name is M2600R, and its melt flow rate is 26g / 10min (test condition: 230 ° C × 2.16Kg) ; Described low molecular weight polypropylene is the L-MODU produced by Japan's Idemitsu TM Low molecular weight polypropylene, the trade name is S600, the density is 0.87g / cm 3 The described anti-scratch auxiliary agent is oleic acid amide, and the production company is Croda Xipu Chemical (Sichuan) Co., Ltd., and the trade name is Sipoamide-OR. The PE wax is provided by Qingdao Sino Company, the model is 118C; the linear low density polyethylene LLDPE is LLDPE-8320 produced by Sinopec Zhenhai Refining and Chemical; the main antioxidant is DSTP produced by the Brit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com