Method for controlling surface appearance of hot-dip galvanized ultra-deep drawing steel for automobile panel

A technology of surface morphology and control method, which is applied in the field of metallurgy, can solve the problems of affecting the vividness of the paint, the decrease of the peak RPc, and the low soft strength, and achieve the advantages of promoting and applying, ensuring the cooling rate, and excellent deep drawing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

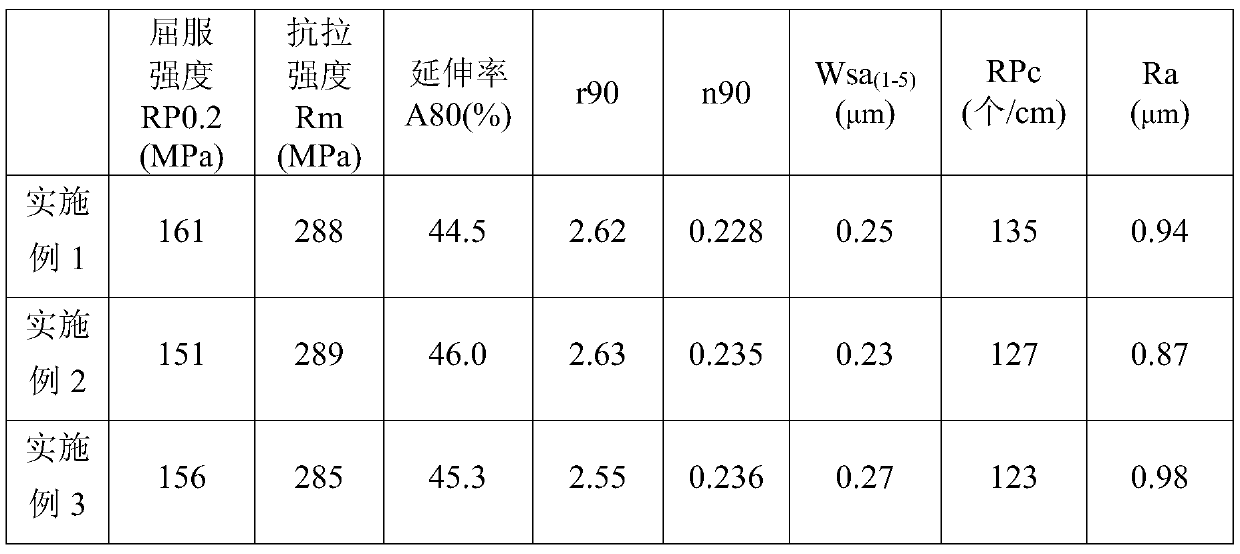

Embodiment 1

[0018] Prepare hot-dip galvanized ultra-deep-drawn steel for automobile panels with high-grade surface morphology. The grade of the hot-dip galvanized ultra-deep-drawn steel is DX56D+Z. Zinc is obtained, and the specific steps are as follows:

[0019] 1) Smelting chemical composition and mass percentage: C 0.0018%, Si 0.003%, Mn 0.15%, P 0.011%, S 0.01%, Als 0.035%, Ti 0.080%, N 0.0031%, the rest is Fe and unavoidable impurities.

[0020] 2) Continuous acid rolling: the roll roughness Ra of the first to fourth stands of the rolling mill is 0.40 μm, 0.40 μm, 0.30 μm, and 0.60 μm respectively; The board roughness is 1.2 μm, and the peak value Rpc=90 pieces / cm.

[0021] 3) Hot-dip galvanizing process: the effective aluminum content in the zinc liquid composition is 0.24%, and the iron content is 0.005%; the temperature of the zinc liquid is 456°C; the speed of the steel strip passing through the zinc pot is 90mpm; the temperature of entering the hot-dip galvanizing zinc pot is 4...

Embodiment 2

[0023] Prepare hot-dip galvanized ultra-deep-drawn steel for automobile panels with high-grade surface morphology. The grade of the hot-dip galvanized ultra-deep-drawn steel is DX56D+Z. Zinc is obtained, and the specific steps are as follows:

[0024] 1) Smelting chemical composition and mass percentage: C 0.0025%, Si 0.020%, Mn 0.10%, P 0.012%, S 0.008%, Als 0.020%, Ti 0.055%, N 0.0025%, the rest is Fe and unavoidable impurities.

[0025] 2) Continuous acid rolling: the roll roughness Ra of the first to fourth stands of the rolling mill is 0.480 μm, 0.80 μm, 0.55 μm, and 0.30 μm respectively; the fifth stand roll roughness Ra=3.5 μm, chilled after acid rolling The plate roughness is 0.6 μm, and the peak value Rpc=92 pieces / cm.

[0026] 3) Hot-dip galvanizing process: the effective aluminum content in the zinc liquid composition is 0.21%, and the iron content is 0.003%; the temperature of the zinc liquid is 455°C; the speed of the steel strip passing through the zinc pot is 1...

Embodiment 3

[0028] Prepare hot-dip galvanized ultra-deep-drawn steel for automobile panels with high-grade surface morphology. The grade of the hot-dip galvanized ultra-deep-drawn steel is DX56D+Z. Zinc is obtained, and the specific steps are as follows:

[0029] 1) Smelting chemical composition and mass percentage: C 0.0012%, Si 0.008%, Mn 0.12%, P 0.007%, S 0.005%, Als 0.050%, Ti 0.070%, N 0.0040%, the rest is Fe and unavoidable impurities.

[0030] 2) Continuous acid rolling: the roll roughness Ra of the first to fourth stands of the rolling mill is 0.55 μm, 0.50 μm, 0.60 μm, and 0.40 μm respectively; Roughness is 0.6μm, peak value Rpc=95 pieces / cm.

[0031]3) Hot-dip galvanizing process: the effective aluminum content in the zinc liquid composition is 0.228%, and the iron content is 0.005%; the temperature of the zinc liquid is 456°C; the speed of the steel strip passing through the zinc pot is 110mpm; The inlet temperature of the top roll of the cold rolling tower is 170°C; the ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com