Preparation method of copper-aluminum composite plate strip

A copper-aluminum composite plate and copper plate technology, applied in the field of copper-aluminum composite plate, can solve the problems of affecting the performance of materials and reducing the bonding strength of composite plates and strips, so as to improve the deep drawing performance, easy physical occlusion, and improve the interface bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

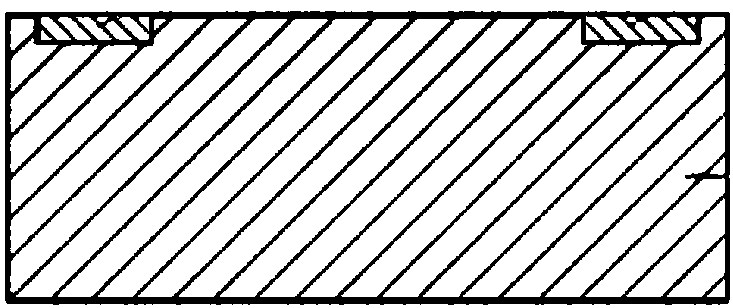

[0033] This embodiment provides a method for preparing a copper-aluminum composite strip, which includes the following steps:

[0034] Step 1. According to the requirements of the finished product, select a copper plate and an aluminum strip whose size meets the requirements, wherein the copper plate is used as the substrate material, and the aluminum strip is used as the embedded material;

[0035] Step 2: Perform uniform annealing treatment on the copper plate: the annealing temperature is 320-400°C, the holding time is 0.5-3h, and perform the homogenizing annealing treatment on the aluminum strip: the annealing temperature is 180-220°C, the holding time is 1-3h, Water quench the copper plate and aluminum strip after annealing;

[0036] Step 3. Perform surface pretreatment on the copper plate and aluminum strip to remove oil stains, surface scale and other impurities, and polish the surface roughness of the embedded groove of the copper plate to 60~80 μm, and polish the surf...

Embodiment 2

[0046] On the basis of Embodiment 1, this embodiment further provides a transformable implementation mode, which differs from Embodiment 1 in that:

[0047] In step five, heat treatment includes the following steps:

[0048] a. Under the protection of inert gas, perform annealing heat treatment on the copper-aluminum cold-rolled clad plate: gradually raise the temperature to 320 ° C ~ 360 ° C, keep it for 1 ~ 3 hours and then cool to room temperature;

[0049] B. carrying out several times of cold finish rolling to the copper-aluminum composite plate after step a processing;

[0050] c. Under the protection of mixed gas of nitrogen and hydrogen, heat-treat the copper-aluminum composite panel treated in step b again: the treatment temperature is 480°C~560°C, and the treatment time is 2~5min, and then the finished product is obtained.

[0051] In step b, 5-8 passes of cold finish rolling are performed at a rolling speed of 10-20 m / min.

[0052] In step c, when the composite st...

Embodiment 3

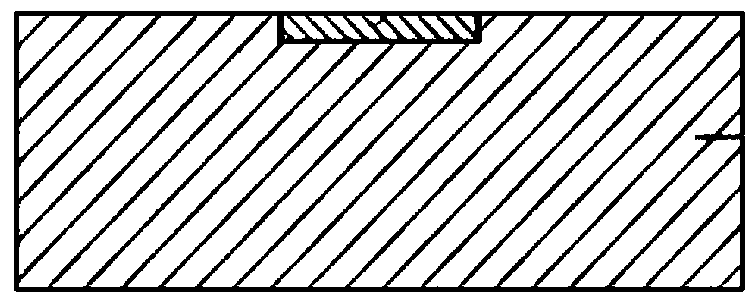

[0055] Such as figure 2 As shown, on the basis of Example 1, this embodiment further provides a specific embodiment, the purpose of which is to prepare a copper-aluminum composite strip with a double composite aluminum strip with an overall thickness of 2.00mm and an aluminum strip thickness of 0.15mm ; Concrete preparation method is as follows:

[0056] Step 1. Select a copper plate with a thickness of 20.00mm as the substrate material, and select an aluminum strip with a thickness of 1.5mm as the embedded material;

[0057] Step 2: Carry out uniform annealing treatment on the copper plate: the annealing temperature is 370°C, the holding time is 2h, and the aluminum strip is subjected to homogenizing annealing treatment: the annealing temperature is 190°C, the holding time is 1.5h, after the annealing is completed, the copper plate and aluminum with water quenching;

[0058] Step 3: Clean the copper plate and aluminum strip with a concentration of 10% NaOH solution to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com