Hot-rolled high-strength steel plate for electrostatic enamel and method for manufacturing same

A technology of high-strength steel plate and manufacturing method, applied in temperature control, manufacturing tools, heat treatment process control, etc., can solve problems such as unsuitability of double-sided wet enamel steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The main components of steel include: C: 0.05%, Si: 0.02%, Mn: 0.86%, P: 0.011%, S: 0.005%, Al: 0.039%, N: 0.004%, Ti: 0.05%, Nb: 0.030%, the balance being iron and unavoidable impurities.

[0043] The molten steel smelted according to the above ratio is subjected to vacuum degassing treatment before continuous casting, and the obtained continuous casting slab is heated at 1150°C, and then rolled in multiple passes within the austenite recrystallization temperature range, the total reduction rate is not low 50%, and then rolled into a steel plate in one or more passes within the temperature range of the austenite recrystallization zone or non-recrystallization zone, the total reduction rate is not less than 50%, and the final rolling temperature is 875°C. Then cool to the coiling temperature in two stages, the water cooling speed of the first stage is 90°C / s, the water cooling speed of the second stage is not less than 20°C / s, the overall average cooling rate is 22°C / s,...

Embodiment 2

[0046] The main components of steel include: C: 0.10%, Si: 0.04%, Mn: 0.80%, P: 0.035%, S: 0.032%, Al: 0.010%, N: 0.007%, Ti: 0.04%, Nb: 0.050%, the balance being iron and unavoidable impurities.

[0047] The implementation method is the same as in Example 1, wherein the cooling process is divided into three sections, and the thickness of the steel plate after rolling is 1.5 mm.

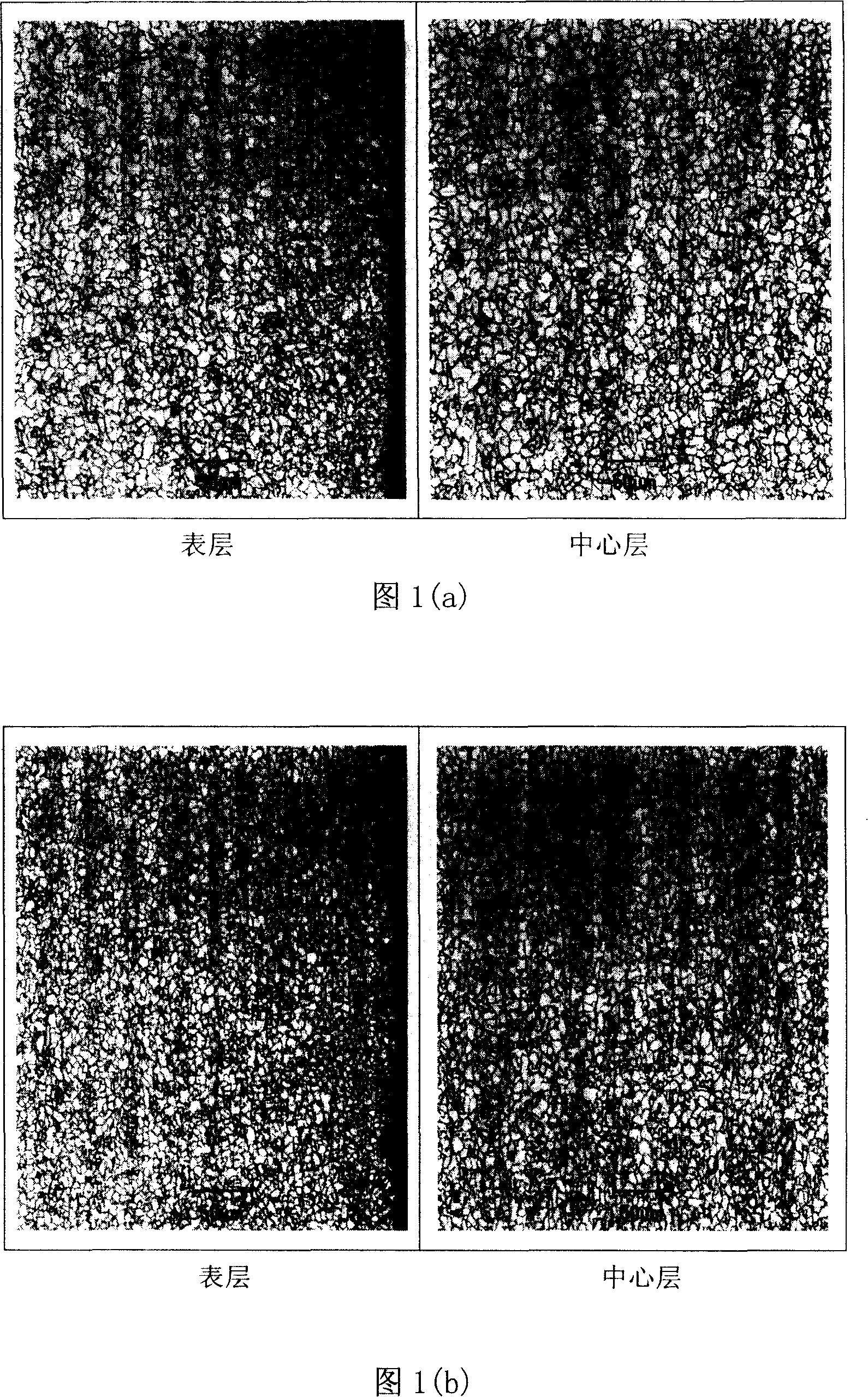

[0048] The metallographic structure of the steel plate of this embodiment is shown in Fig. 1(b).

Embodiment 3

[0050] The main components of steel include: C: 0.04%, Si: 0.06%, Mn: 0.85%, P: 0.011%, S: 0.035%, Al: 0.042%, N: 0.007%, Ti: 0.10%, Nb: 0.005%, the balance being iron and unavoidable impurities.

[0051] The implementation method is the same as in Example 1, wherein the thickness of the steel plate after rolling is 2.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com