Works for enameling and enameled products

A technology for processing products and enamel, which is applied in the field of processed products for enamel glazing, and can solve the problems that cannot be omitted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

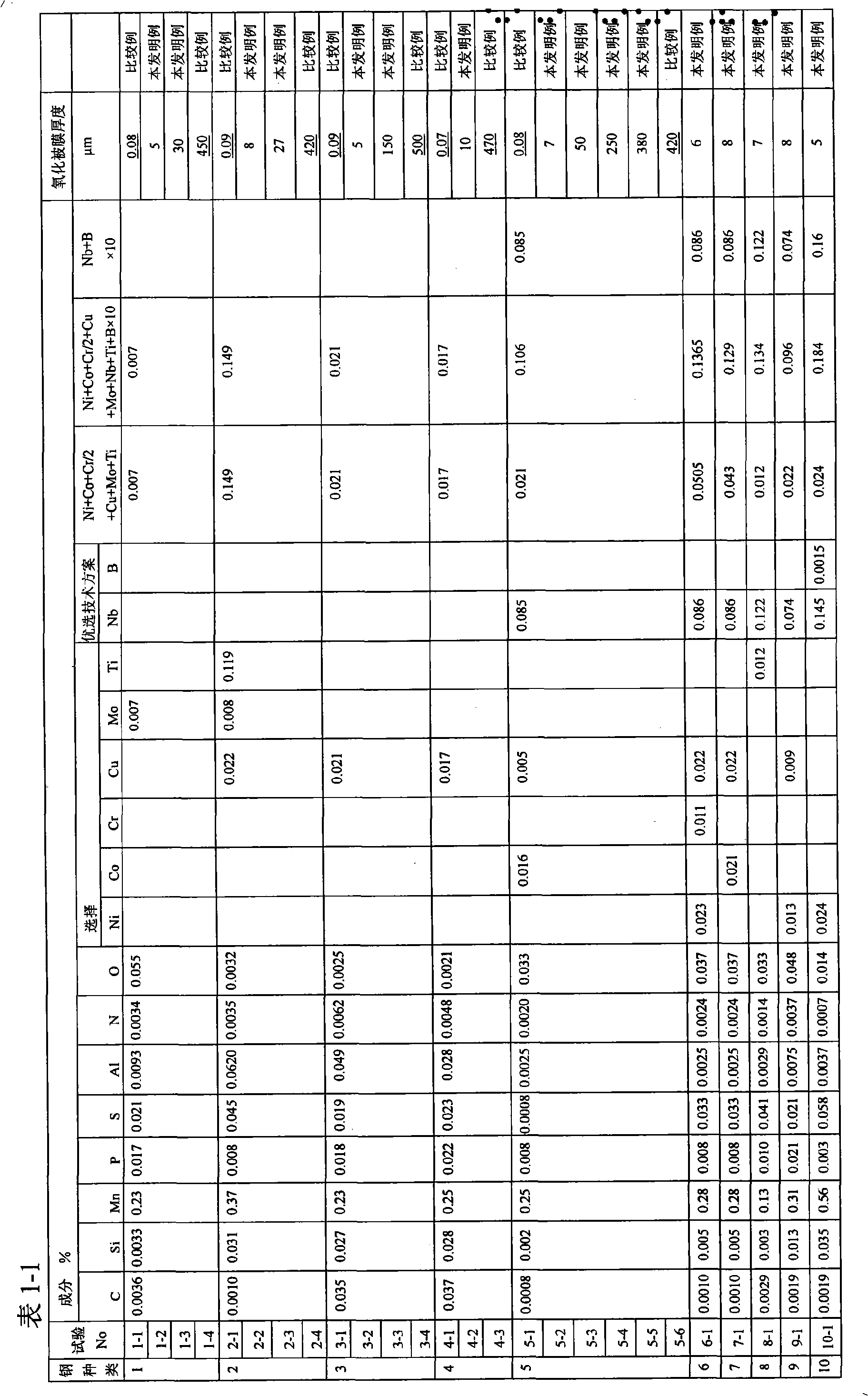

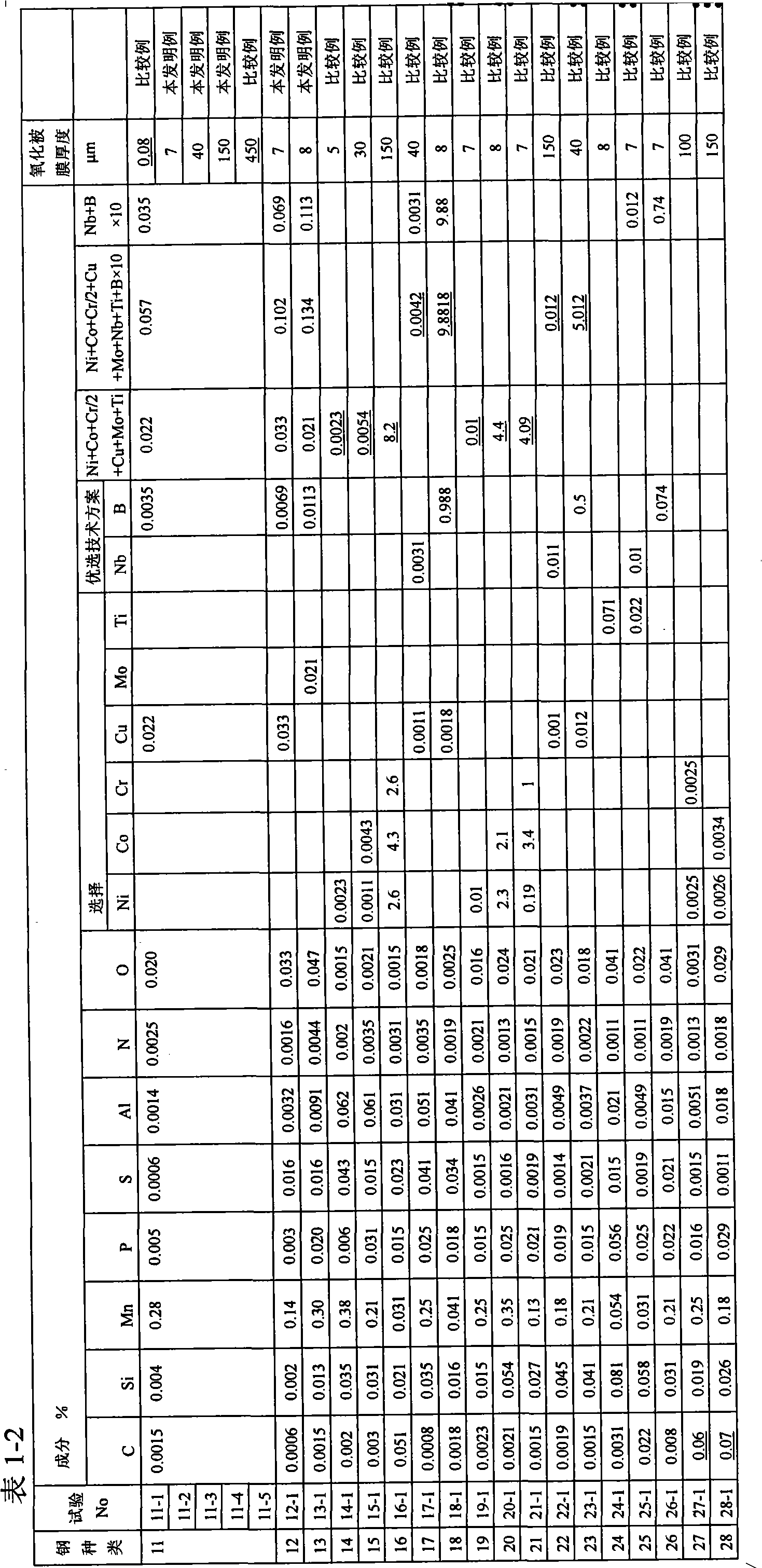

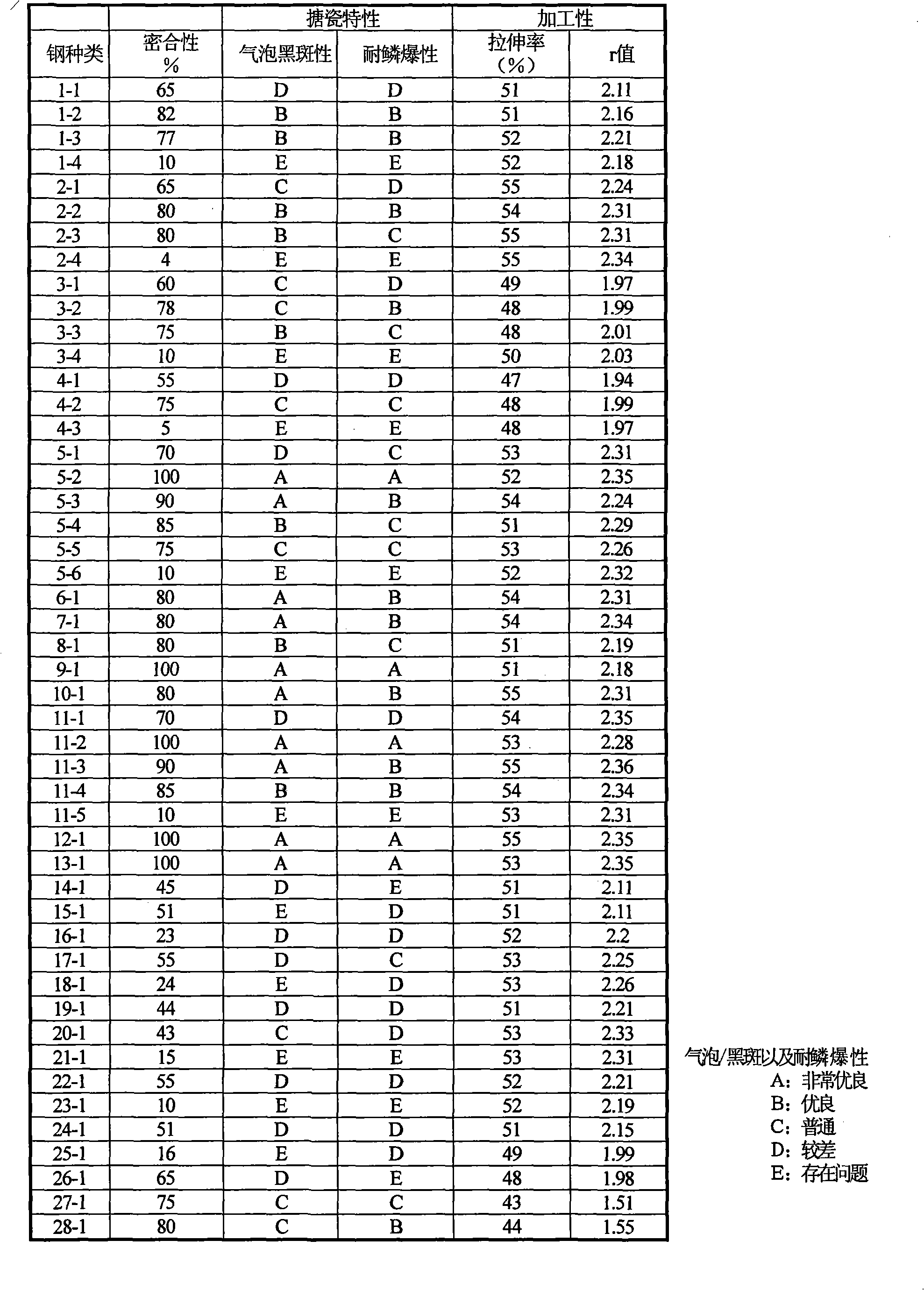

[0083] Hereinafter, the effects of the present invention will be specifically described with reference to examples of the present invention and comparative examples deviating from the scope of the present invention.

[0084] First, as an example of the present invention, hot rolling, cold rolling, annealing, and 1.0% conditioning were performed on continuously cast steel ingots with various chemical compositions shown in Table 1-1 and Table 1-2 under various manufacturing conditions. Quality rolling to produce a steel plate with a thickness of 0.8mm. At this time, an oxide film is also formed on the surface of the steel sheet. Next, glazing was applied to this steel plate, and the characteristics of enamel were investigated. In glazing, a 100 μm glaze agent for the top glaze layer is dry-coated by a powder electrostatic coating method. Underglaze coating is not performed.

[0085]

[0086]

[0087] In Table 1-1 and Table 1-2, steel types 1 to 13 consist of components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com