Method for producing blackboard and whiteboard made from enamel in super strength, and glaze of enamel

A technology for enamel glaze and a manufacturing method, applied in the field of stationery, can solve the problems of inability to ensure dimensional stability, thermal deformation of thin steel plates, brittle and toughness of enamel, etc., and achieve the effects of strong hardness, low cost and good adhesion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] In the present invention, the enamelling temperatures of the bottom glaze and the surface glaze should differ by more than 80°C. Because the process of enamel firing is the process of melting and releasing. If the enamelling temperature of the bottom glaze and the top glaze is too low, pinholes and air bubbles will easily occur when the top glaze is enamelled.

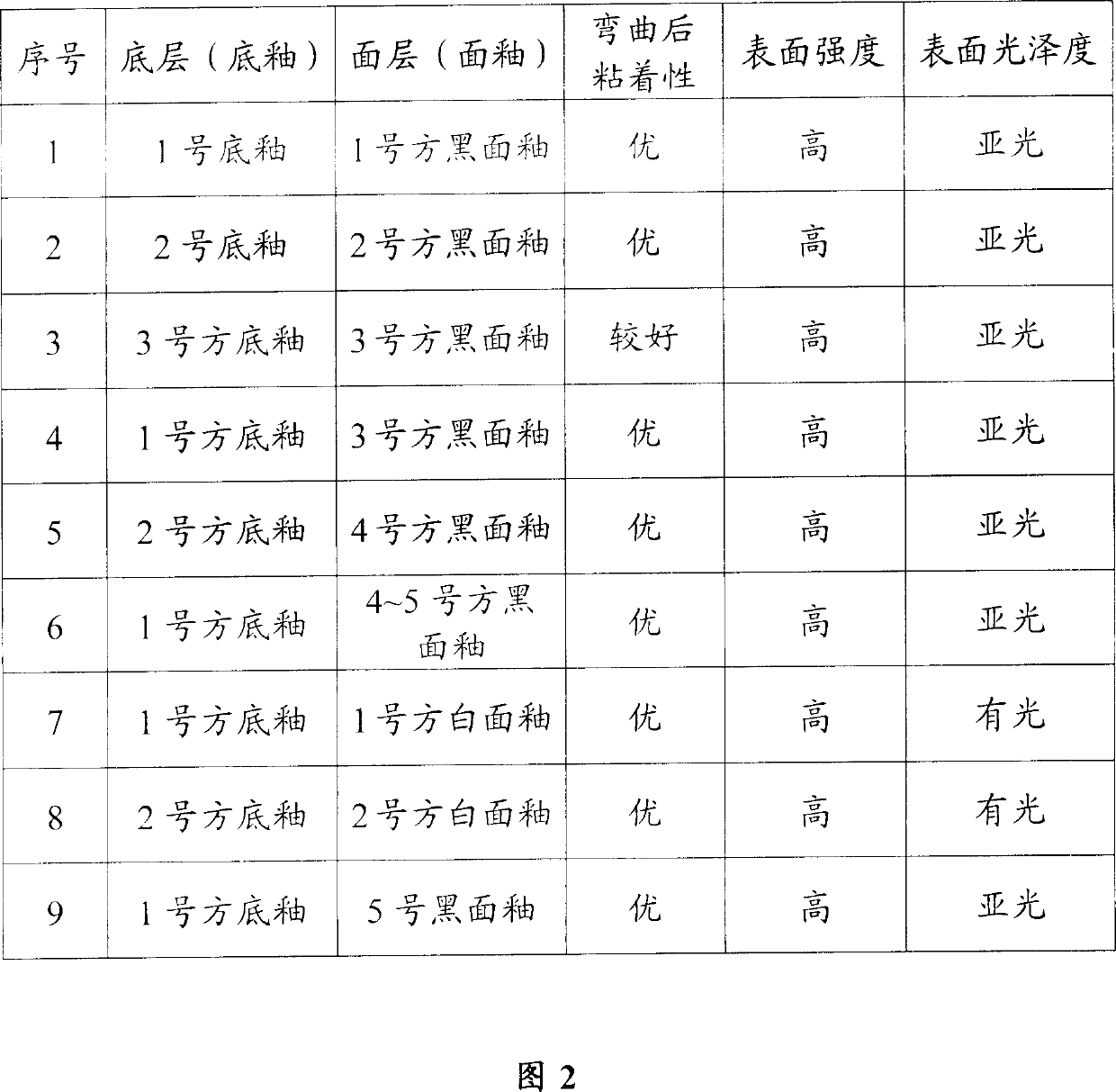

[0013] 1. The manufacture and enamel firing process of the bottom glaze

[0014] Weigh chemical raw materials according to the formula listed in Figure 1, and mix them thoroughly through pulverization. When the heating temperature of the rotary kiln reaches 1200°C, pour the mixture into the kiln, and the kiln body continues to be heated, rotated and stirred. The mixture is allowed to fully react and melt to form a melt. After being tested by wire drawing, knot measuring, bending and other methods, the molten material is poured into cold water and cooled to form crushed glass-like crystals, which are the raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com