Enamel steel with scaling resistance and manufacturing method thereof

A manufacturing method, enamelled steel technology, applied in the direction of temperature control, etc., can solve the problems of enameled steel smelting cost and production control difficulty, and achieve good anti-scale explosion performance, reduce smelting cost, and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

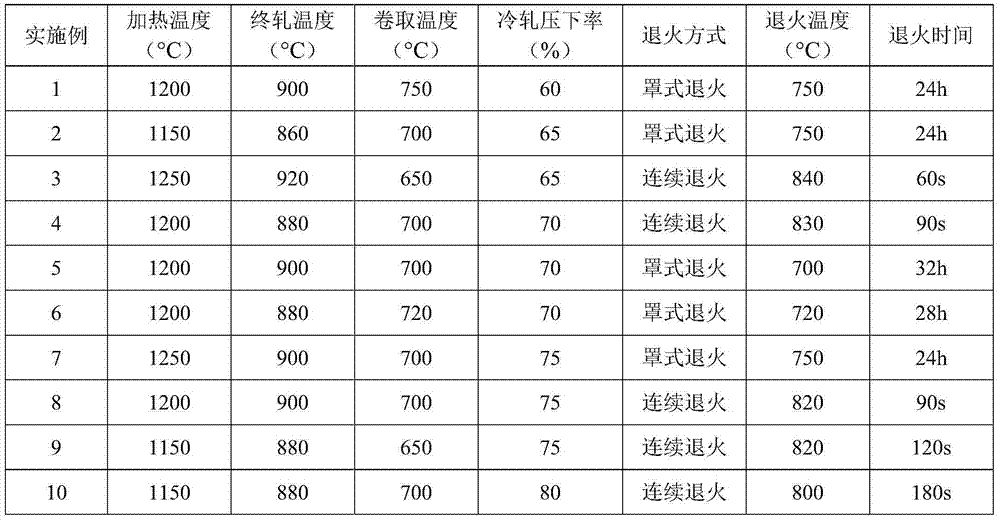

Embodiment 1

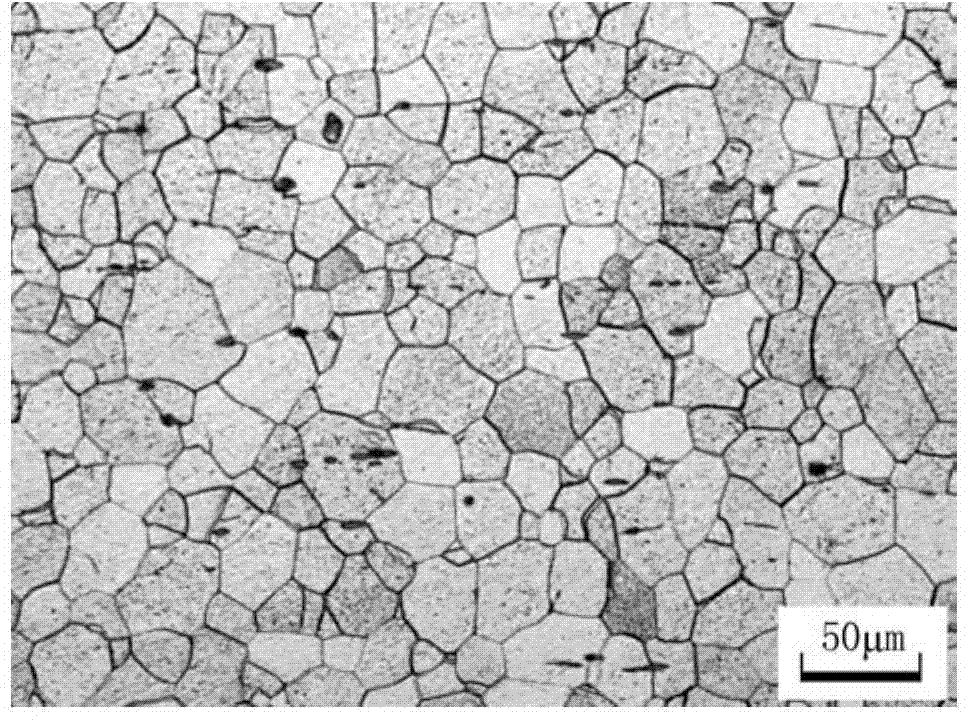

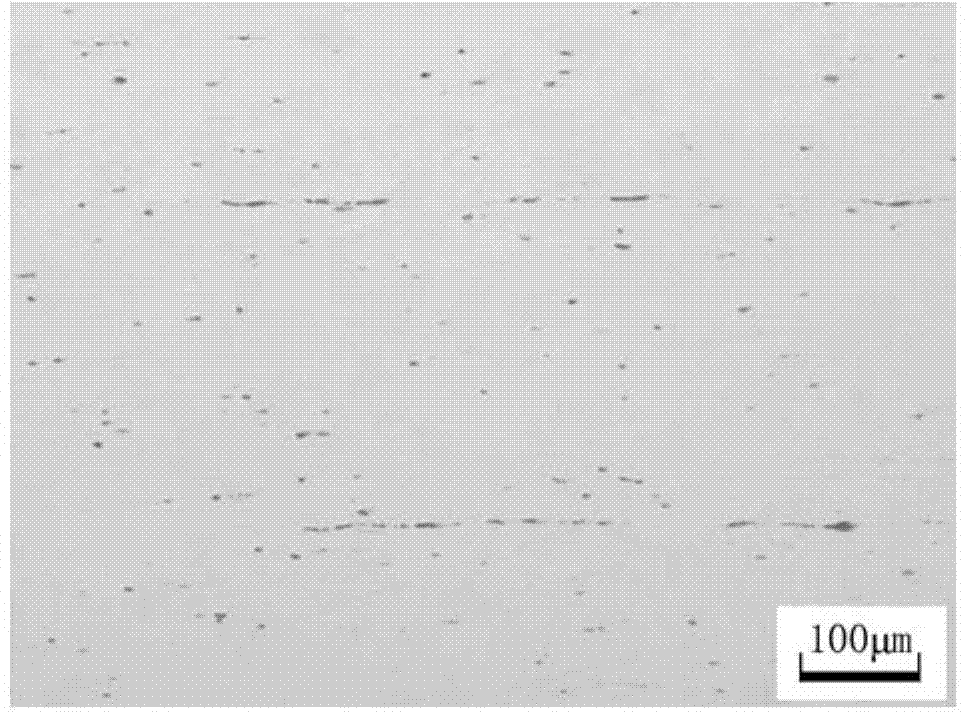

[0022] In this example, the enamelled steel with scale explosion resistance is made of the following components and weight percentages: C: 0.0020%, Mn: 0.41%, Si: 0.0050%, P: 0.012%, S: 0.012%, Als: 0.003%, O: 0.018%, and the balance is Fe and other unavoidable impurities.

[0023] The manufacturing method of enamelled steel with anti-scaling explosion performance comprises the following steps in sequence: molten iron pretreatment, converter smelting, refining, continuous casting, hot continuous rolling, pickling, cold continuous rolling, annealing, finishing, wherein, the hot The heating temperature in the continuous rolling process is 1200°C, the final rolling temperature is 900°C, and the coiling temperature is 750°C; the cold rolling reduction in the cold continuous rolling process is 60%; the annealing process is bell annealing , the annealing temperature is 750°C, the annealing time is 24h, and the flat elongation is 0.3%.

[0024] After inspection, the yield strength R...

Embodiment 2

[0026] This example is basically the same as Example 1, except that the enamelled steel with scale explosion resistance is made of the following components and weight percentages: C: 0.0028%, Mn: 0.36%, Si: 0.0089%, P: 0.015%, S: 0.011%, Als: 0.003%, O: 0.013%, and the balance is Fe and other unavoidable impurities.

[0027] A method for manufacturing enamelled steel with scale explosion resistance, wherein the heating temperature in the hot continuous rolling process is 1150°C, the final rolling temperature is 860°C, and the coiling temperature is 700°C; in the cold continuous rolling process The cold rolling reduction rate is 65%.

[0028] After inspection, the steel plate yield strength R p0.2 is 147MPa, the tensile strength R m 290MPa, elongation A 80mm It is 42.8%, the isotropic plastic index r value is 2.1, the work hardening index n value is 0.20, has good formability, and the hydrogen permeation time is 18min / mm.

Embodiment 3

[0030] This example is basically the same as Example 1, except that the enamelled steel with scale explosion resistance is made of the following components and weight percentages: C: 0.0031%, Mn: 0.45%, Si: 0.0083%, P: 0.012%, S: 0.015%, Als: 0.008%, O: 0.020%, the balance is Fe and other unavoidable impurities.

[0031] A method for manufacturing enamelled steel with scale explosion resistance, wherein the heating temperature in the hot continuous rolling process is 1250°C, the final rolling temperature is 920°C, and the coiling temperature is 650°C; in the cold continuous rolling process The cold rolling reduction rate is 65%; the annealing process is continuous annealing, the annealing temperature is 840°C, the annealing time is 60s, and the flat elongation is 0.4%.

[0032] After inspection, the steel plate yield strength R p0.2 162MPa, tensile strength R m 298MPa, elongation A 80mm It is 41.1%, the r value of the isotropic plasticity index is 1.9, the work hardening in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com