Economical deep drawing cold rolling enamel steel and production method

A production method and an economical technology, applied in the field of metal materials, can solve problems such as increasing costs, and achieve the effects of saving production costs, good adhesion performance, and good anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

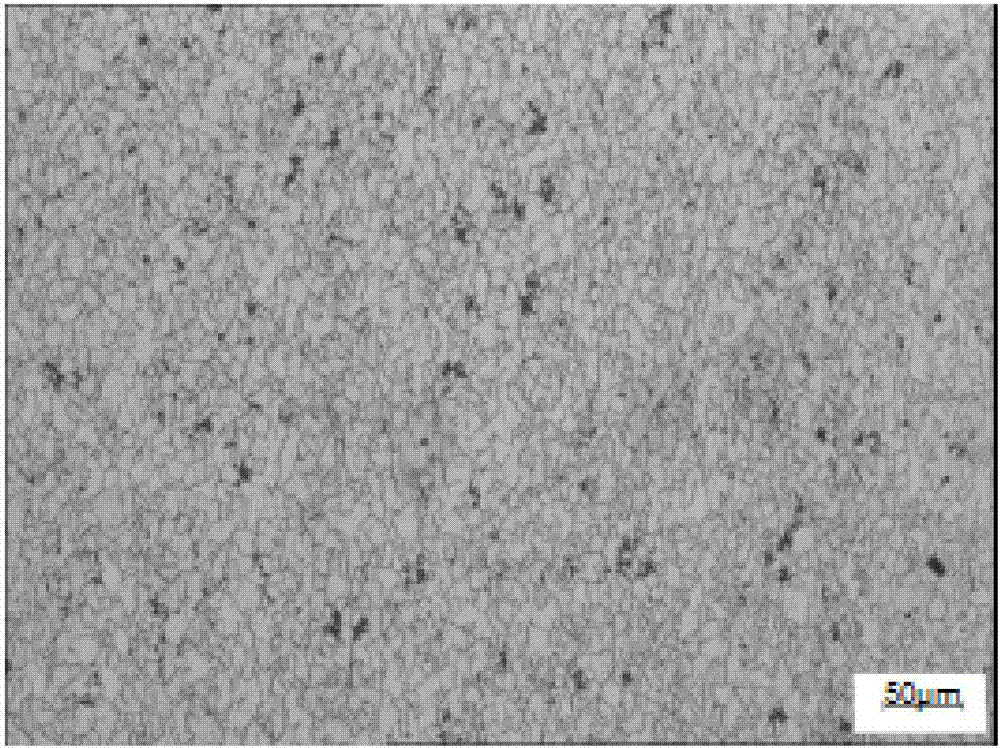

[0033] An economical deep-drawing cold-rolled enamel steel, including the following chemical elements and weight percentages: C: 0.005~0.015%, Si≤0.030%, Mn: 0.15%~0.25%, P≤0.020%, S: 0.010~0.020 %, Al: 0.030%~0.060%, N≤0.0040%.

[0034] The production method is:

[0035] 1) Hot metal pretreatment: requires front and rear slagging;

[0036] 2) Converter smelting: no pig iron and slag steel are added; self-circulating scrap steel tapping is used to strengthen converter dephosphorization and slag blocking operations; lime is added during tapping without deoxidation;

[0037] 3) Alloy fine-tuning station: carry out ladle top slag modification;

[0038] 4) RH furnace refining: RH adopts a light treatment process. If oxygen is required to be blown, oxygen is blown in the early and mid-term according to the temperature and oxygen level; ensure that the net cycle time is not less than 6min before breaking the world;

[0039] 5) The temperature of casting slab is controlled at 1180℃~1200℃;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com