Cold rolling glass-lined steel having excellent scale cracking resistance and extra-deep drawing property and manufacturing method thereof

A manufacturing method and anti-scaling explosion technology, applied in the field of cold-rolled enamelled steel and its manufacturing, can solve the problems of poor formability of steel plates and failure to achieve ultra-deep drawability, etc., and achieve stable performance, wide adaptability, and ultra-deep drawability The effect of scale resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

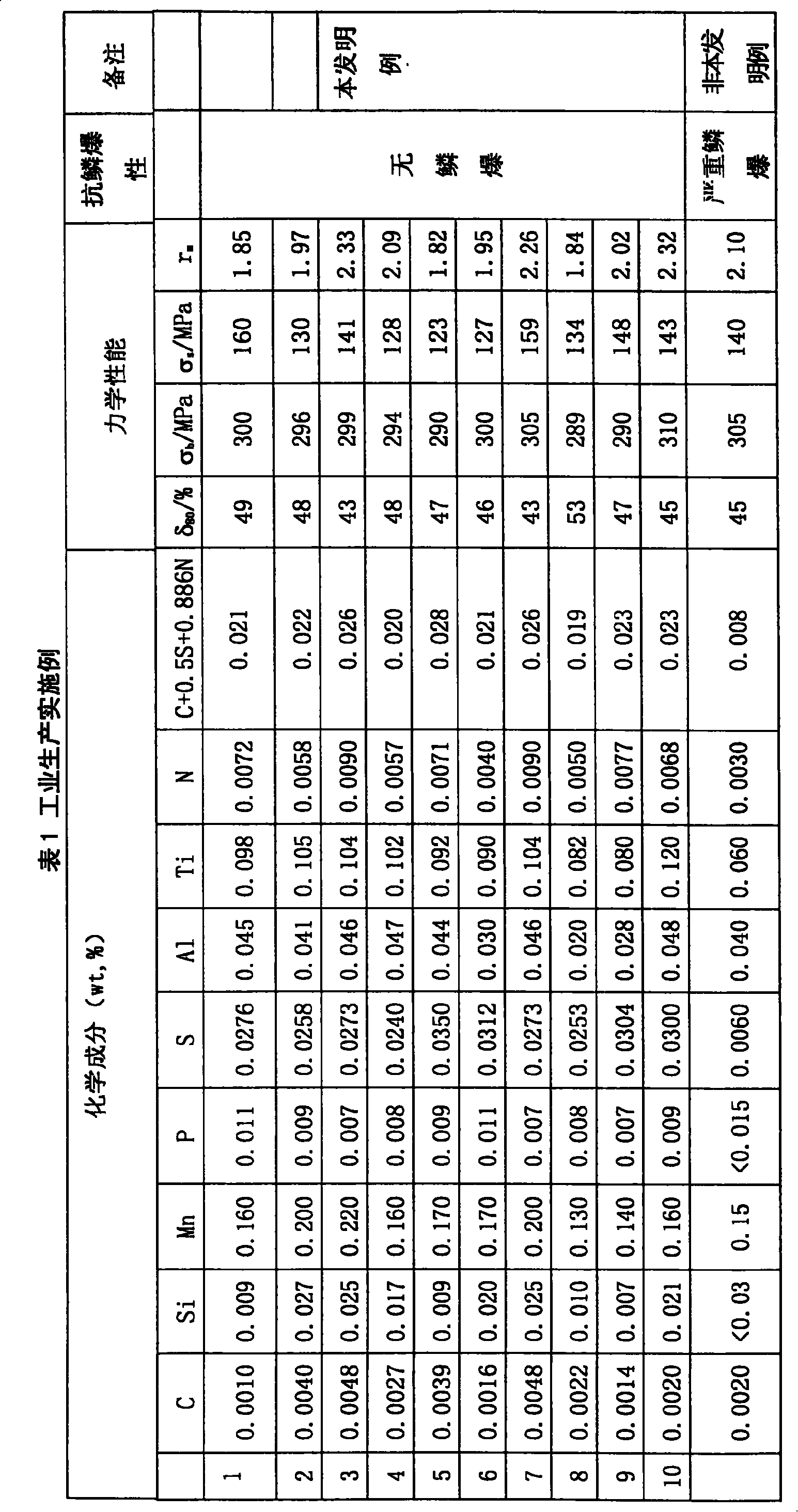

[0032]See Table 1 for Examples 1-10, and add a pair of proportions, with the balance being iron and other unavoidable impurities. Smelting and processing were carried out according to the process of the technical plan. Examples 1-5: heating temperature of hot rolling 1150°C, finishing temperature 880°C, coiling temperature 700°C, cold rolling reduction rate 66%, bell annealing temperature: 700°C, The nitrogen content of the bell annealing is 6%. Example 6-10 The heating temperature of hot rolling is 1200°C, the final rolling temperature is 900°C, the coiling temperature is 730°C, the cold rolling reduction rate is 67.5%, the bell annealing temperature is 700°C, and the nitrogen content of the bell annealing is 8%. The performance of the finished product is shown in Table 1. It can be seen from Table 1, that the elongation rate of the finished product performance is 43-53% (gauge length 80mm), with an average of 47%, three-way r m The value is 1.82~2.33, and the average is 2.05, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com