Hot-rolled steel plate for enameled high-strength double-face enamel and manufacturing method of steel plate

A technology of hot-rolled steel plate and manufacturing method, which is applied in the field of low-alloy hot-rolled steel plate manufacturing, can solve the problems that cannot meet the needs of large-scale enamel assembly structural engineering, and achieve the effect of good scale explosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

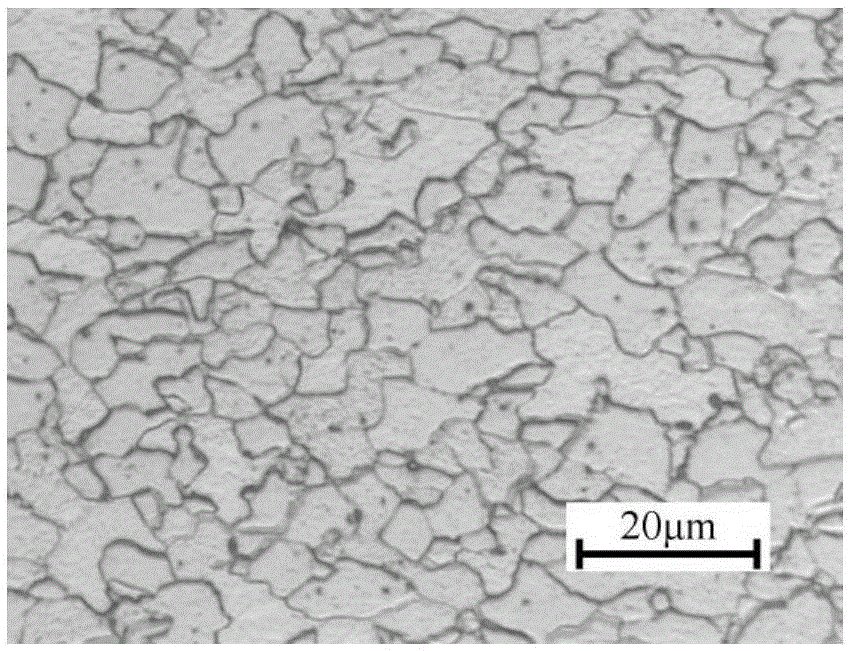

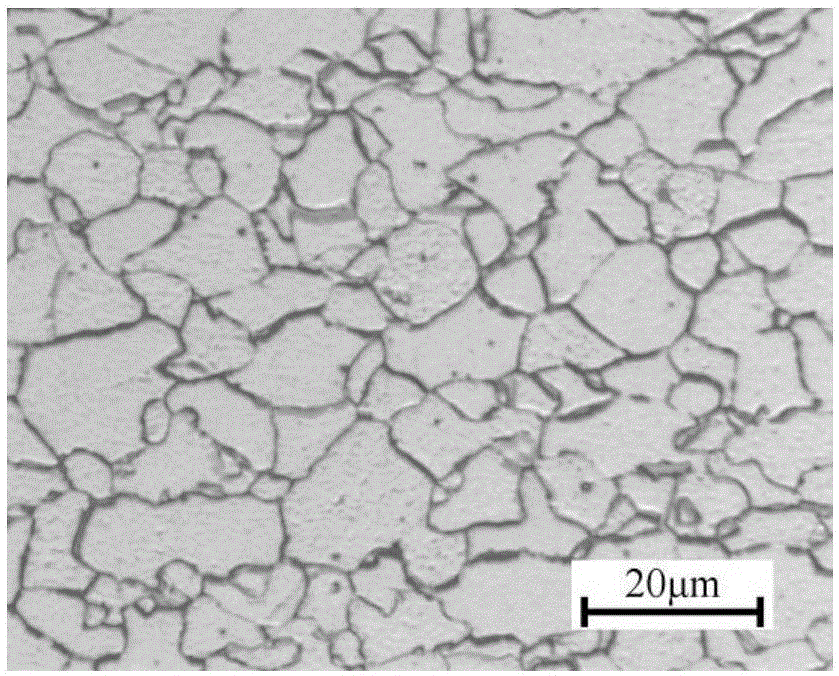

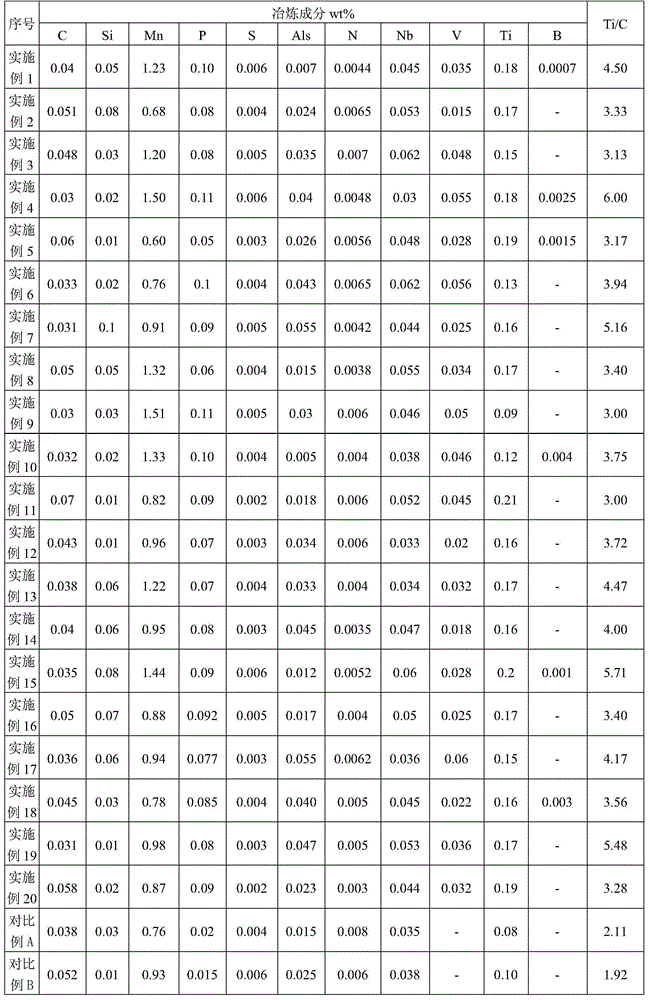

[0041] The technical problems involved in the present invention are solved by the following technical solutions: a hot-rolled steel sheet for enamelling high-strength double-sided enamel and a manufacturing method thereof, the mass percentage of its chemical composition is: C: 0.030%-0.070%, Si≤0.10% , Mn: 0.60% to 1.5%, P: 0.05% to 0.11%, S≤0.006%, N≤0.008%, Ti: 0.09% to 0.21%, Nb: 0.03% to 0.07%, V: 0.015% to 0.060% , Als: 0.005% to 0.055%. Ti / C: 3.0 to 6.0, B can be added according to different plate thicknesses, the content of elements to be added is B: 0.0005% to 0.005%, and the balance is Fe and inevitable impurities. The continuous casting billet of the above-mentioned components is heated to 1180-1250 ℃, and after soaking, it is descaled by high-pressure water, rough-rolled to open the billet, the finishing rolling temperature is 880-1100 ℃, and the final rolling temperature is 880-930 ℃. ≥30℃ / S cooling speed is fast cooling to the coiling temperature, and the coiling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com