Hot-rolling high-strength medium plate for double-face enamel and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve the problems that are not suitable for the production of medium and thick steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A8

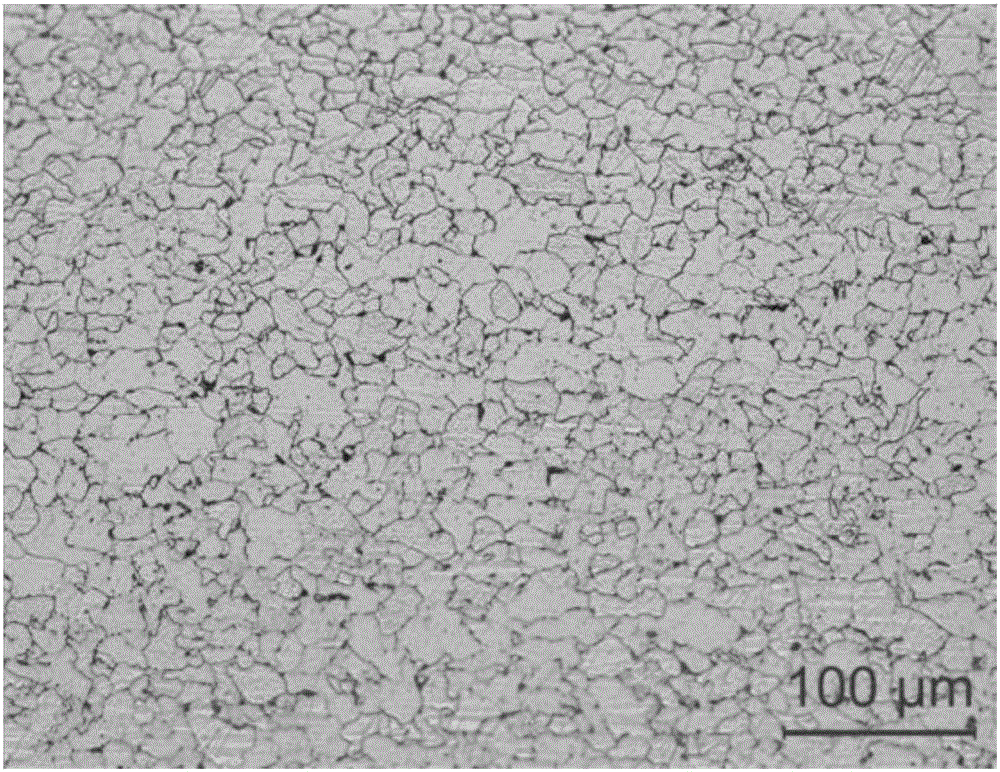

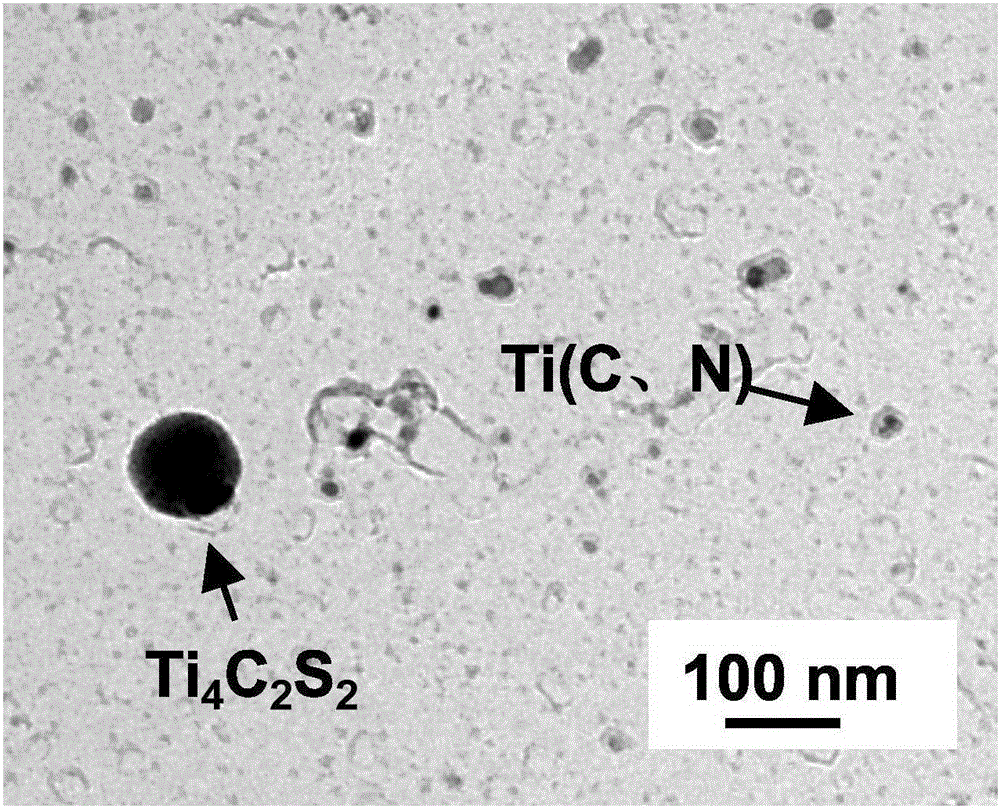

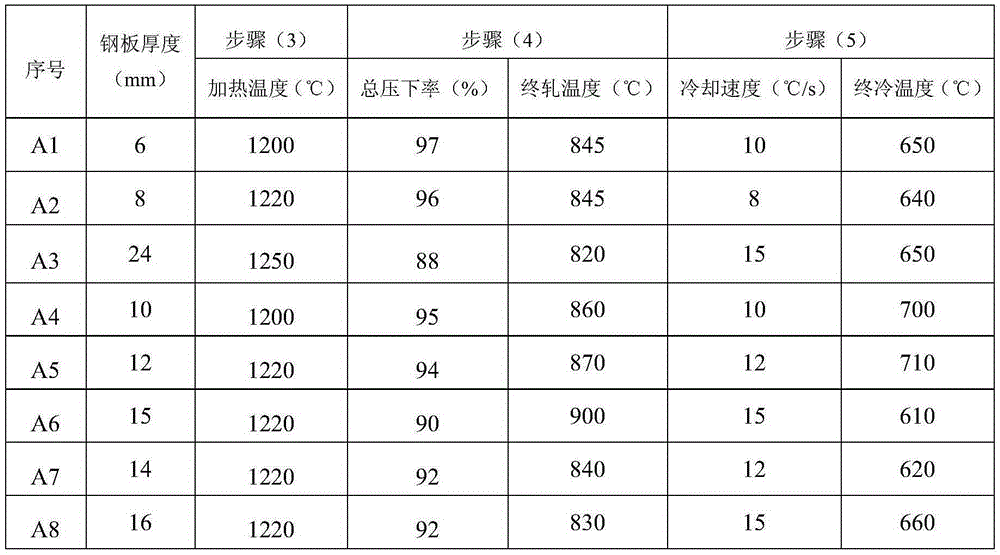

[0064] According to the following steps, the hot-rolled high-strength medium and thick plates for double-sided enamel in the embodiments of the present invention A1-A8 are manufactured (the mass percentages of each chemical element in the steel plates of each embodiment are as shown in Table 1, and the mass percentages of the steel plates of each embodiment Concrete process parameters are as shown in table 2):

[0065] 1) Smelting: smelting+vacuum degassing, adding alloying elements to the molten steel, and adjusting the alloying elements, removing harmful gases such as hydrogen in the steel, to ensure that the mass percentage of each chemical element in the steel plate is as shown in Table 1;

[0066] 2) Casting: continuous casting or die casting;

[0067] 3) Heating: the heating temperature is 1100-1250°C;

[0068] 4) Hot rolling: multi-pass rolling is carried out at the austenite recrystallization temperature and non-recrystallization temperature, the total reduction rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com