Enamel steel, as well as preparation method and application thereof

A technology of enamel steel and mass percentage, which is applied in the field of hot-rolled enamel steel, can solve the problems of affecting the service life of the inner tank of the water heater, poor adhesion between the steel plate and the glaze, and low strength level of the enamel steel, so as to achieve good anti-scaling performance and high Strength Roughness, high adhesion strength grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In another aspect, the present invention provides a method for preparing the enamelled steel, comprising: (1) continuously casting molten iron with qualified components into a slab; (2) heating the slab, and cooling it after hot rolling (3) Enamel steel is obtained after coiling, smoothing, shot blasting and pickling.

[0039] Wherein, the molten iron, by mass percentage, includes: C: 0.01%-0.14%, Si≤0.10%, Mn: 0.20%-1.6%, P≤0.040%, S≤0.040%, Ti: 0.01%-0.12 %, Al: 0.01%-0.07%, N≤0.010%, Mn / S≥30, the rest is Fe and unavoidable impurities; preferably, by mass percentage, including: C: 0.01%-0.12%, Si: 0.01%-0.10%, Mn: 0.30%-1.6%, P≤0.035%, S≤0.035%, Ti: 0.01%-0.10%, Al: 0.01%-0.06%, N≤0.008%, Mn / S≥30 , the rest are Fe and unavoidable impurities; more preferably, by mass percentage, including: C: 0.02%-0.10%, Si: 0.01%-0.08%, Mn: 0.35%-1.5%, P≤0.030%, S≤0.030%, Ti: 0.02%-0.10%, Al: 0.02%-0.06%, N≤0.007%, Mn / S≥30, and the rest are Fe and unavoidable impurities.

[0040] ...

Embodiment 1

[0055] The thick 2mm of the enamelled steel plate of the present embodiment, wide 1180mm, the mass percentage distribution of its chemical composition is as follows:

[0056] C: 0.07%, Si: 0.06%, Mn: 1.15%, P: 0.010%, S: 0.012%, Ti: 0.06%, Al: 0.05%, N: 0.006%, Mn / S: 96%, the rest is Fe with unavoidable impurities.

[0057] The preparation method of present embodiment enamelled steel is as follows:

[0058] 1. Continuous casting into slab after converter smelting and out-of-furnace refining (LF+RH), the size of the slab is 230mm×1200mm.

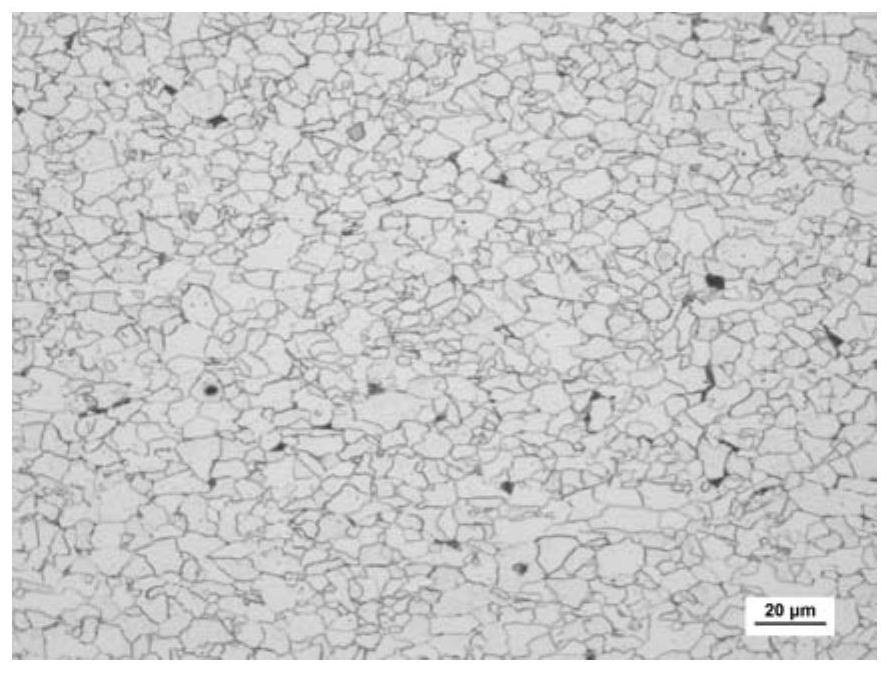

[0059] 2. Heat the slab to 1280°C, and roll it through multiple passes in the rough rolling mill, with a cumulative deformation rate of over 70%; for finishing rolling, use a multi-stand hot rolling unit to roll the slab to the target thickness of 2mm, with a cumulative deformation rate of over 70%. More than 70%, the final rolling temperature is 890°C, the laminar flow cooling method is used to cool and then coiled, and the coiling tempera...

Embodiment 2-7 and comparative example 1-3

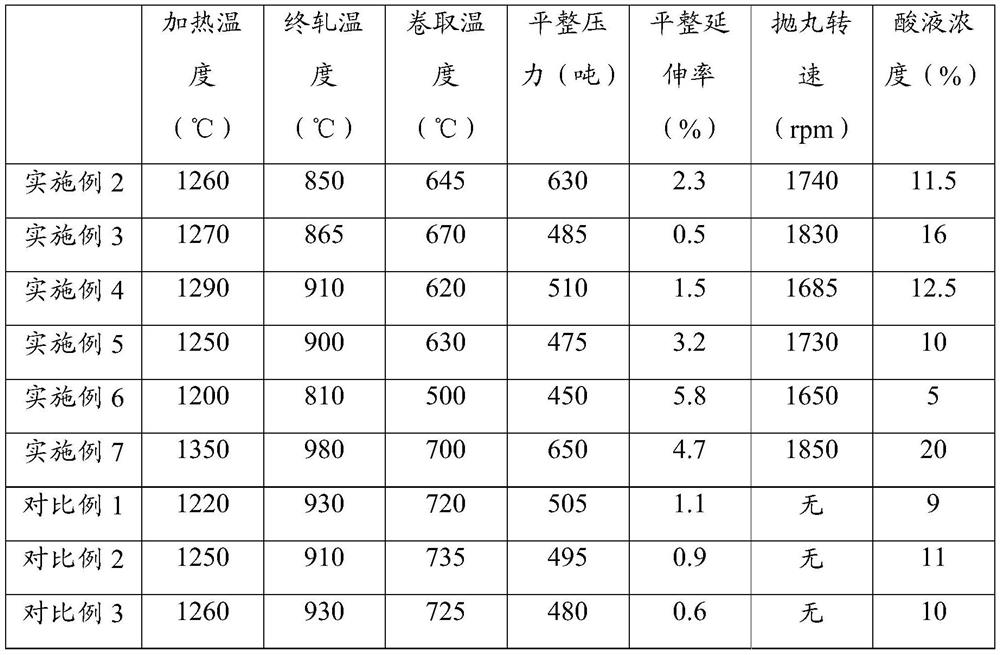

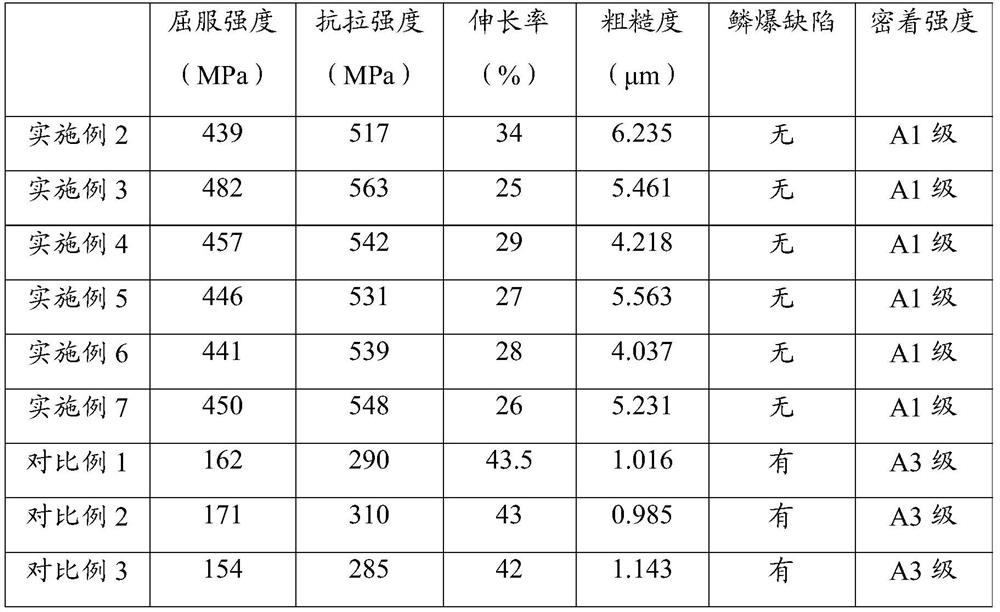

[0064] Next, using the same rolling process and shot blasting process as in Example 1, the continuous casting slabs of the same size and specification were prepared into enamelled steel of the same size and specification. Among them, the composition of the enamelled steel in each embodiment and comparative example is shown in Table 1, the main preparation process parameters of the enamelled steel in each embodiment and comparative example are shown in Table 2, and the performance test results of the prepared enamelled steel are shown in Table 3.

[0065] Table 1 Example 2-7 and the enamelled steel composition summary of comparative examples 1-3

[0066] C Si mn P S Ti Al N Mn / S Example 2 0.12 0.01 0.95 0.009 0.021 0.01 0.026 0.002 45 Example 3 0.08 0.05 0.47 0.034 0.008 0.03 0.070 0.005 59 Example 4 0.10 0.08 0.76 0.040 0.009 0.10 0.043 0.007 84 Example 5 0.05 0.07 1.48 0.015 0.040 0.07 0.015 0.008 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com