Enamel steel and preparation method of cold rolled sheet thereof

A technology of enamelled steel and cold-rolled sheet, which is applied in the field of manufacturing enamelled steel and its cold-rolled sheet, which can solve the problems of difficult joining, high cost, and difficult to guarantee yield, and achieve low production cost and excellent scale explosion resistance , Excellent anti-pinhole performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

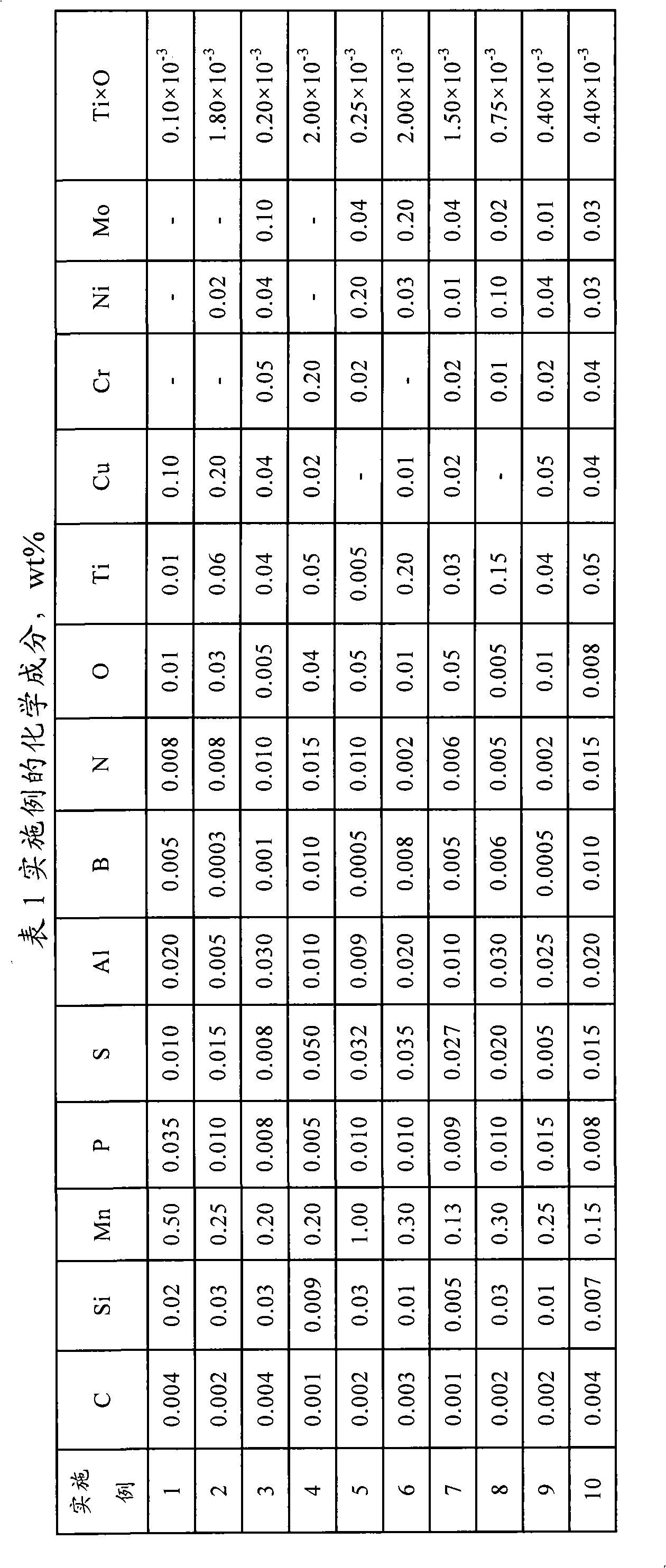

Examples

Embodiment 1

[0063] According to the composition of 1 in Table 1, it is smelted by converter, refined, and then continuously casted. According to the process of 1 in Table 2, the continuous casting slab was heated to 1200°C for rolling, the final rolling temperature was controlled within the range of 850°C, and the coiling temperature was controlled at 750°C. The hot-rolled steel coil is pickled to remove scale and then cold-rolled, and the total reduction ratio of cold-rolling is 75%. The cold-rolled steel coil is continuously annealed, the annealing temperature is 750°C, and the annealing time is 6 minutes. The annealing process ensures that the ferrite structure in the steel completes recrystallization and grain growth.

[0064] Get 1.0mm thick cold-rolled steel plate to carry out mechanical property test, yield strength (R p0.2 ) is 195MPa, the tensile strength (R m ) is 312MPa, elongation (A 80 ) is 43.0%.

[0065] The steel plate is enamelled and sintered after pretreatment such ...

Embodiment 2

[0067] According to the composition of 2 in Table 1, adopt converter smelting, refining treatment, and then die casting. According to the process of 2 in Table 2, the steel ingot is heated to 1250°C for rolling after billeting, the final rolling temperature is controlled within the range of 950°C, and the coiling temperature is controlled at 750°C. The hot-rolled steel coil is pickled to remove scale and then cold-rolled, and the total reduction rate of cold-rolling is controlled at 75%. The cold-rolled steel coil is continuously annealed, the annealing temperature is 850°C, and the annealing time is 3 minutes. The annealing process ensures that the ferrite structure in the steel completes recrystallization and grain growth.

[0068] Get 1.0mm thick cold-rolled steel plate to carry out mechanical property test, yield strength (R p0.2 ) is 150MPa, the tensile strength (R m ) is 290MPa, elongation (A 80 ) is 43.0%.

[0069] The steel plate is enamelled and sintered after pre...

Embodiment 3

[0071] According to the composition of 3 in Table 1, adopt converter smelting, refining treatment, and then carry out continuous casting. According to the process of 3 in Table 2, the continuous casting slab was heated to 1200°C for rolling, the final rolling temperature was controlled within the range of 900°C, and the coiling temperature was controlled at 730°C. The hot-rolled steel coil is pickled to remove scale and then cold-rolled, and the total reduction rate of cold-rolling is controlled at 70%. The cold-rolled steel coil is continuously annealed, the annealing temperature is 850°C, and the annealing time is 3 minutes. The annealing process ensures that the ferrite structure in the steel completes recrystallization and grain growth.

[0072] Get 1.0mm thick cold-rolled steel plate to carry out mechanical property test, yield strength (R p0.2 ) is 149MPa, the tensile strength (R m ) is 305MPa, elongation (A 80 ) is 46.0%.

[0073] The steel plate is enamelled and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com