Enamel steel sheet for direct glazing and manufacturing method thereof

A manufacturing method and direct technology, applied in the field of steel plates, can solve the problems of not being suitable for manufacturing enamel steel products, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

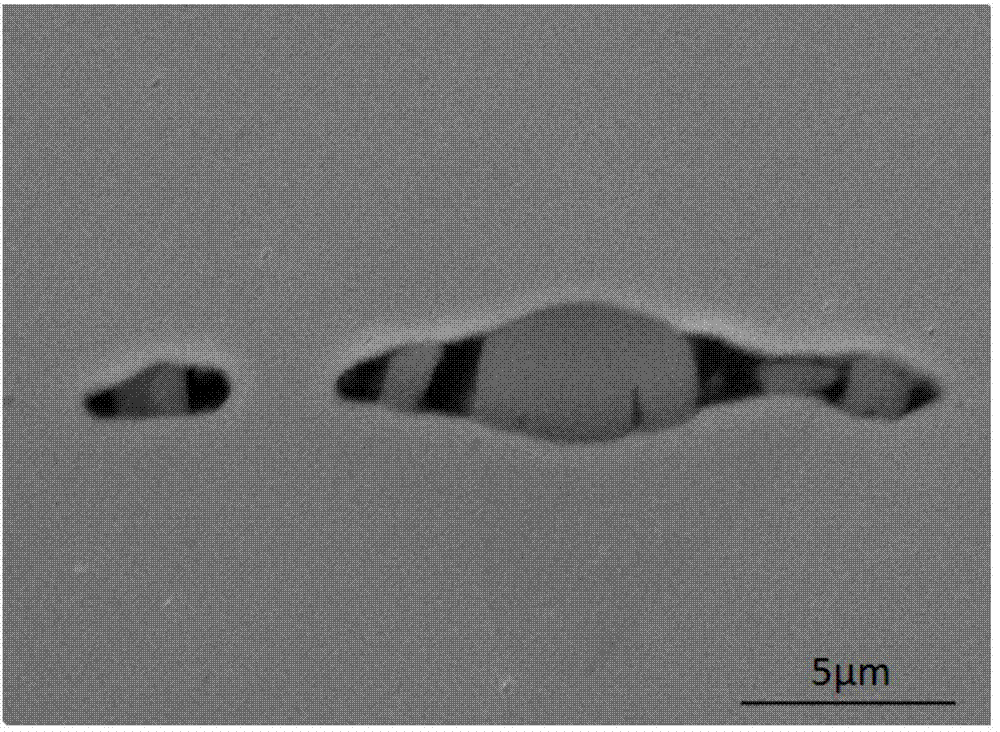

Image

Examples

Embodiment Construction

[0065] The enamelled steel plate for direct glazing and its manufacturing method described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. However, this explanation and illustration do not constitute inappropriate technical solutions of the present invention. limited.

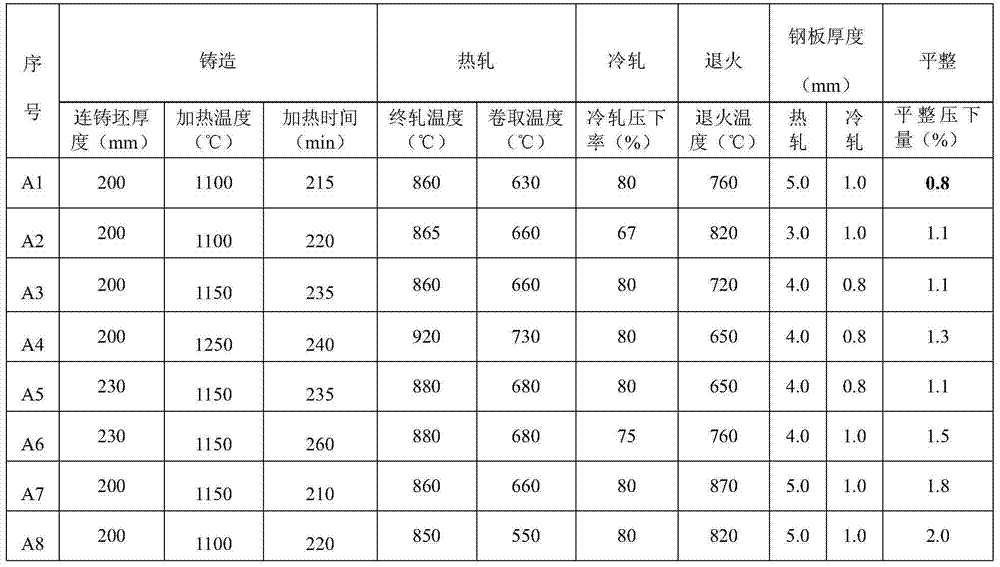

[0066] Manufacture the steel plate for enamelling among the embodiment A1-A8 according to the following steps:

[0067] 1) molten iron pretreatment;

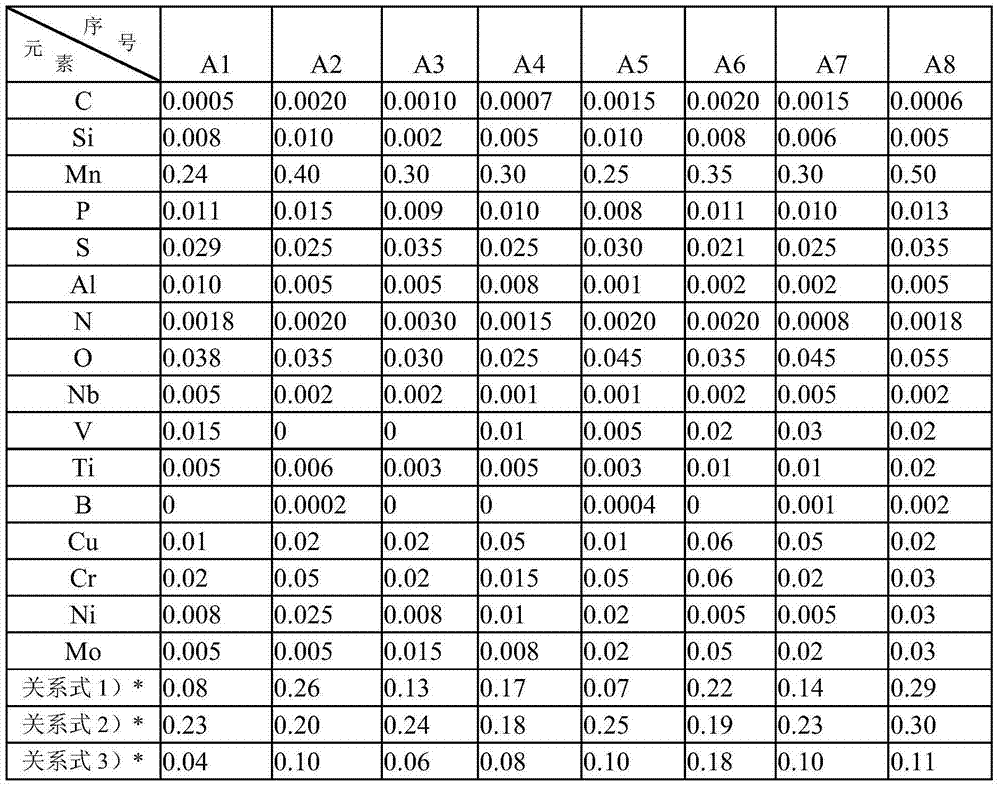

[0068] 2) Smelting and refining: decarburization, dephosphorization, and removal of other residual elements and harmful gases are achieved through the top-bottom combined blowing converter, further removal of harmful gases and residual elements through refining, addition of alloy elements, and oxidation can also be added if necessary Iron powder, make the chemical composition of molten steel reach requirement, control the mass percent distribution ratio of each chemical eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Rm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com