Patents

Literature

74results about How to "Reduce timeliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

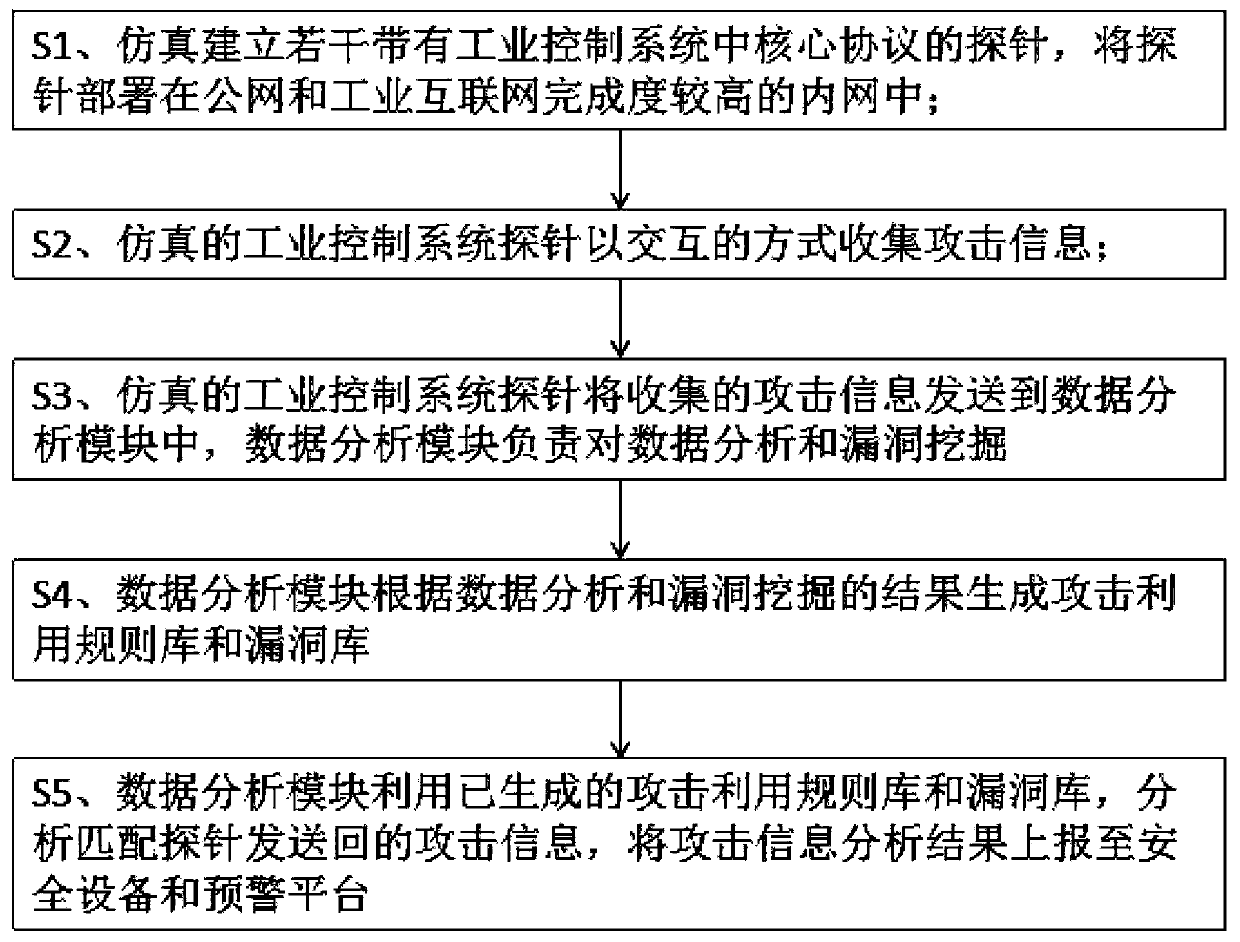

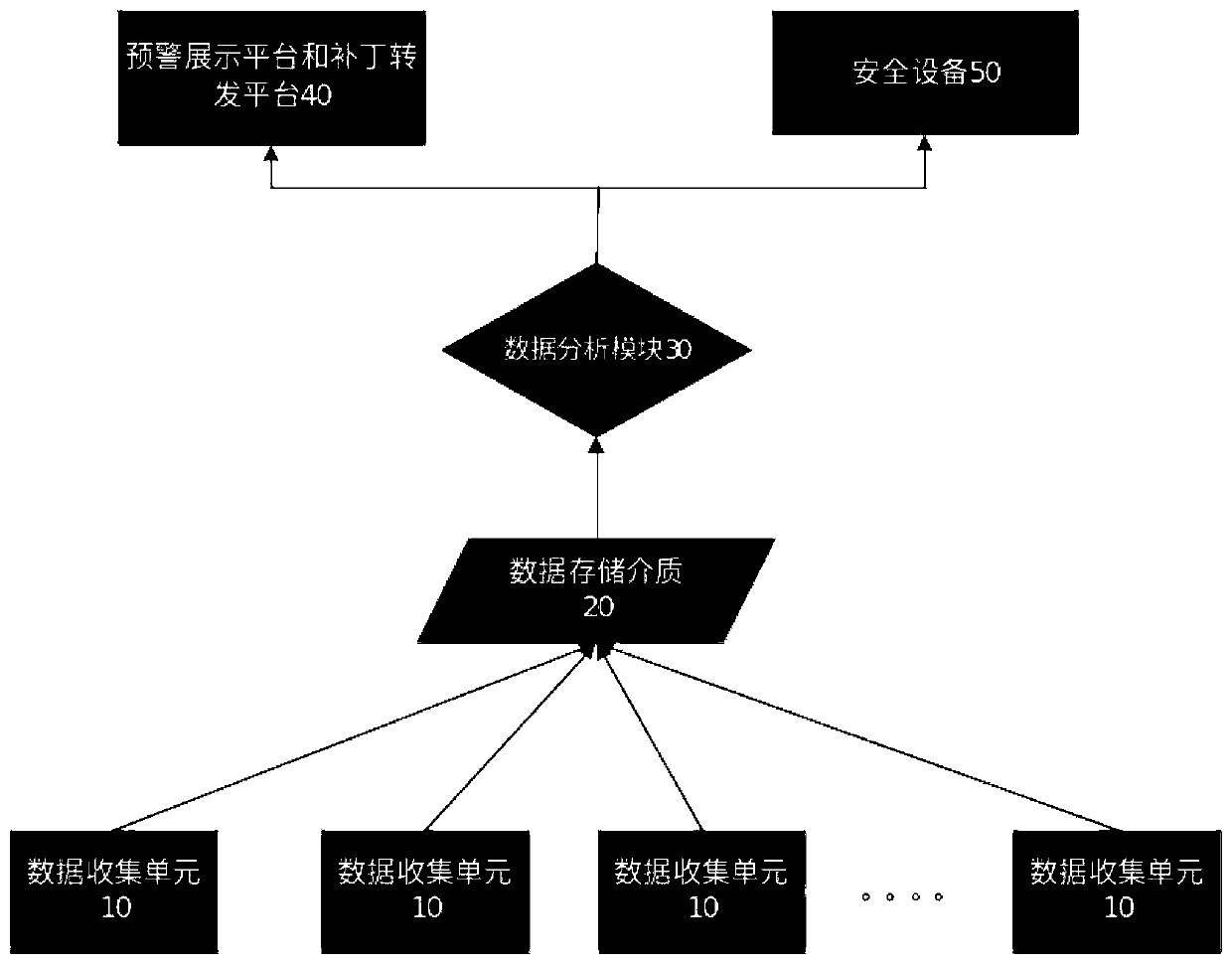

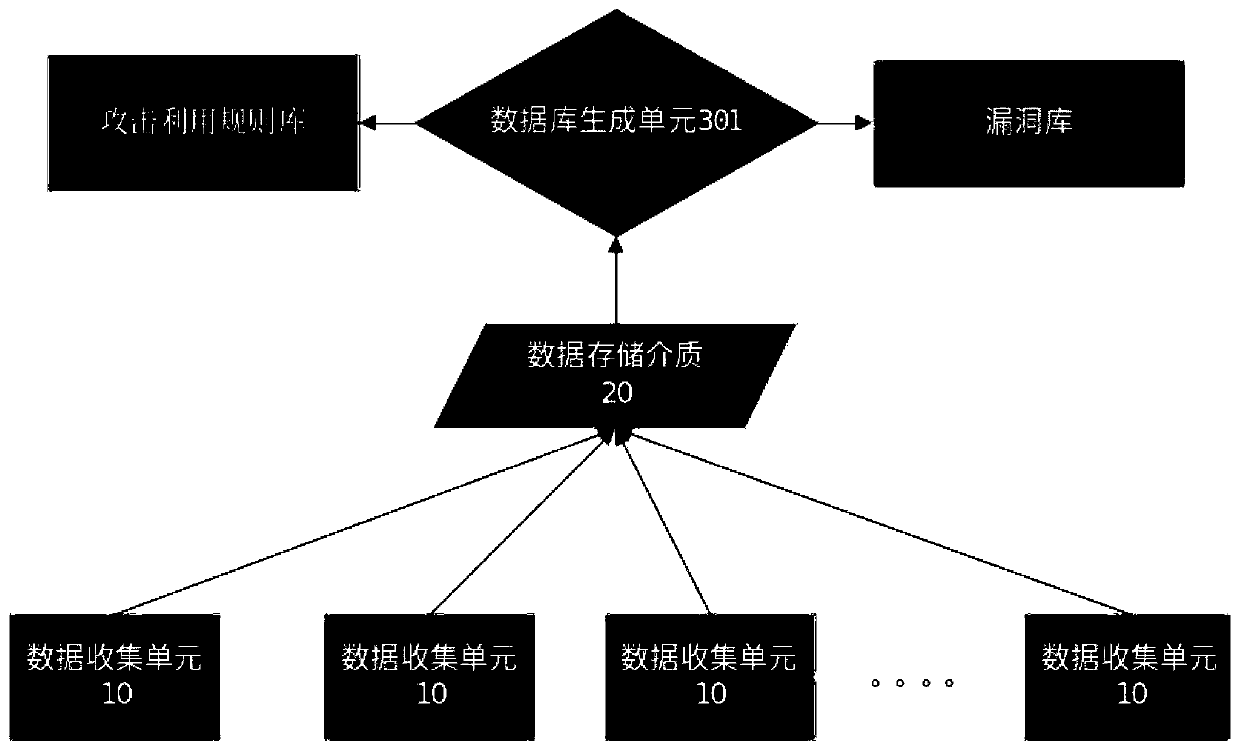

Industrial control system vulnerability trend analysis and early warning method and system

ActiveCN109818985AFix hidden vulnerabilities in a timely mannerAvoid production accidentsData switching networksInformation analysisPublic network

The invention discloses an industrial control system vulnerability trend analysis and early warning method and system, and the method comprises the steps: the simulation establishment of a plurality of probes is carried out with a core protocol in an industrial control system, and enabling the probes to be deployed in a public network and an intranet; The probe collects attack information in an interactive mode; The simulated industrial control system probe sends the collected attack information to a data analysis module, and the data analysis module is responsible for data analysis and vulnerability mining; The data analysis module generates an attack utilization rule base and a vulnerability base according to data analysis and vulnerability mining results; And the data analysis module analyzes the attack information sent back by the matching probe by using the generated attack utilization rule base and the vulnerability base, and reports the analysis result of the attack informationto the security equipment and the early warning display platform. According to the simulation industrial control system, the simulation industrial control system is induced to send an attack to the simulation industrial control system, an attack means is collected, vulnerabilities are analyzed, and serious vulnerability information existing in a production environment or to be utilized is early warned to a user.

Owner:江苏亨通工控安全研究院有限公司

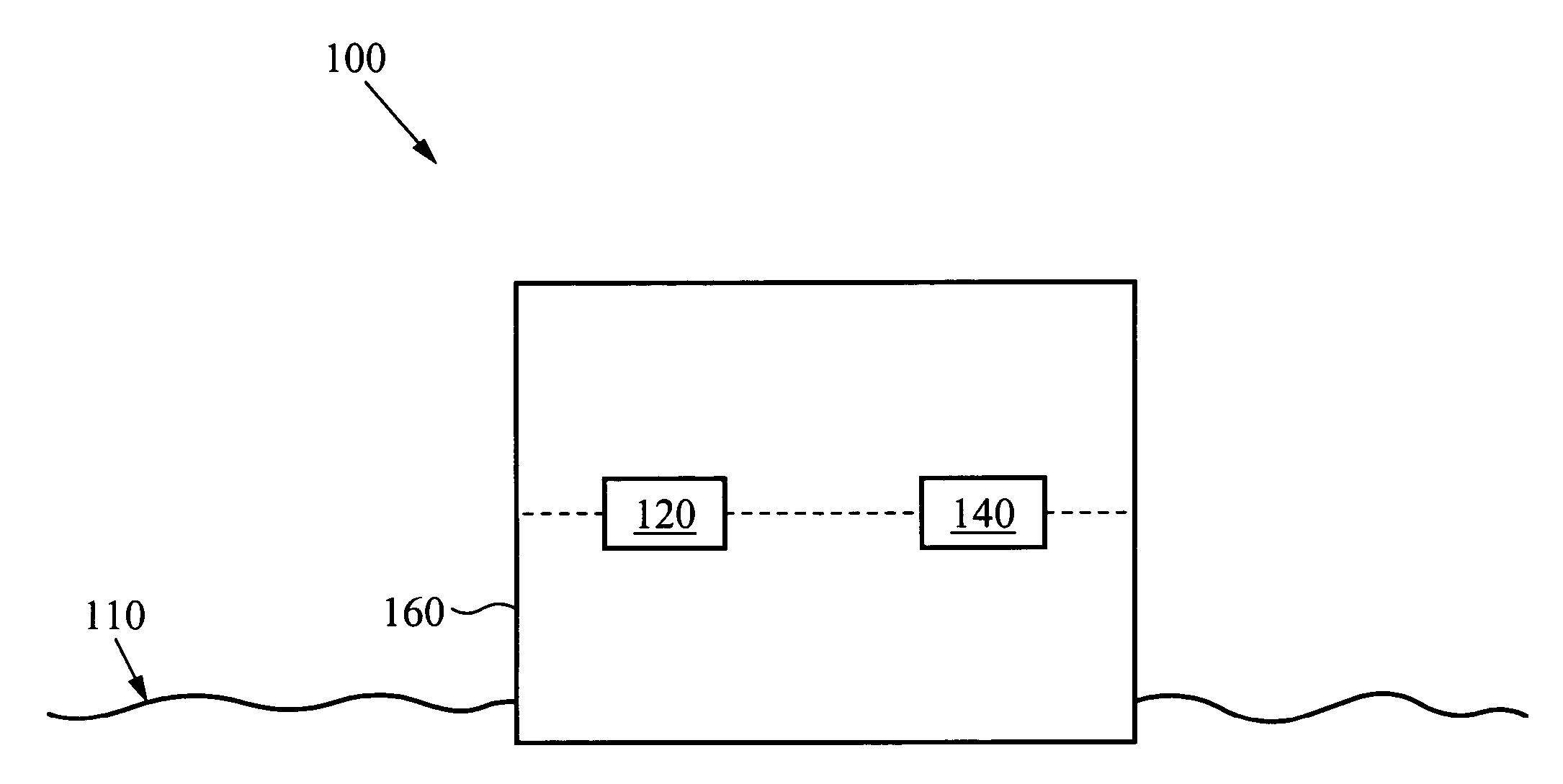

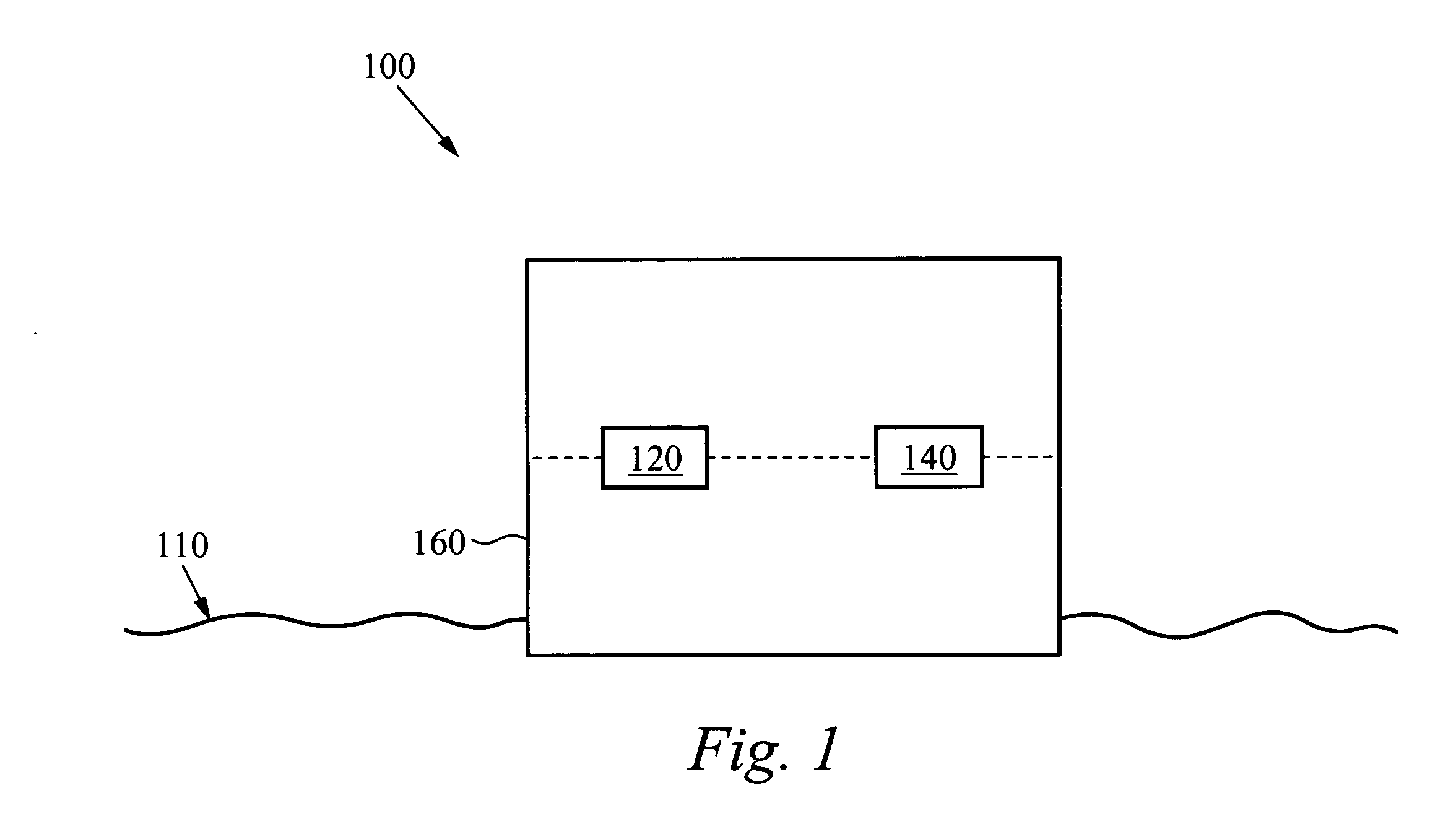

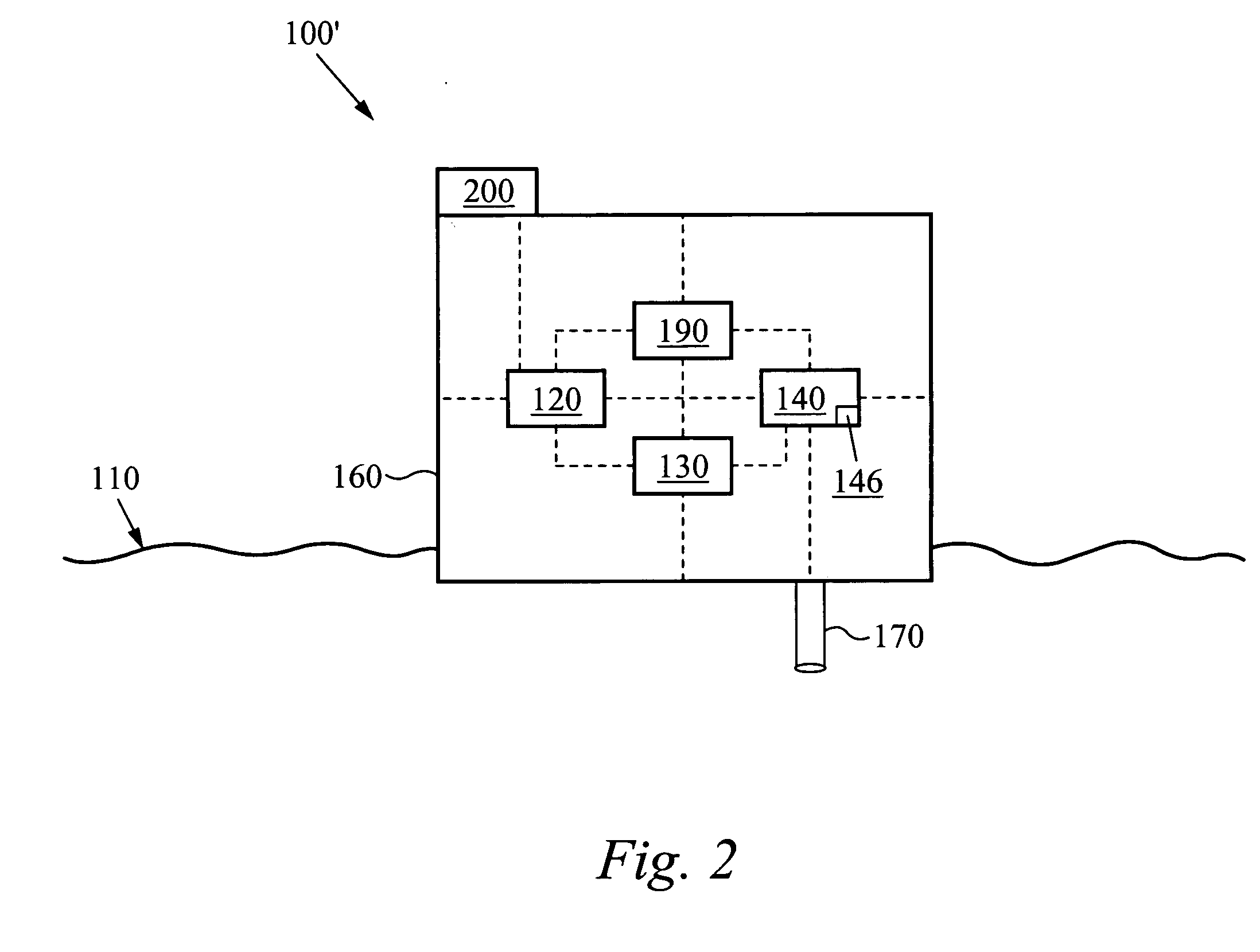

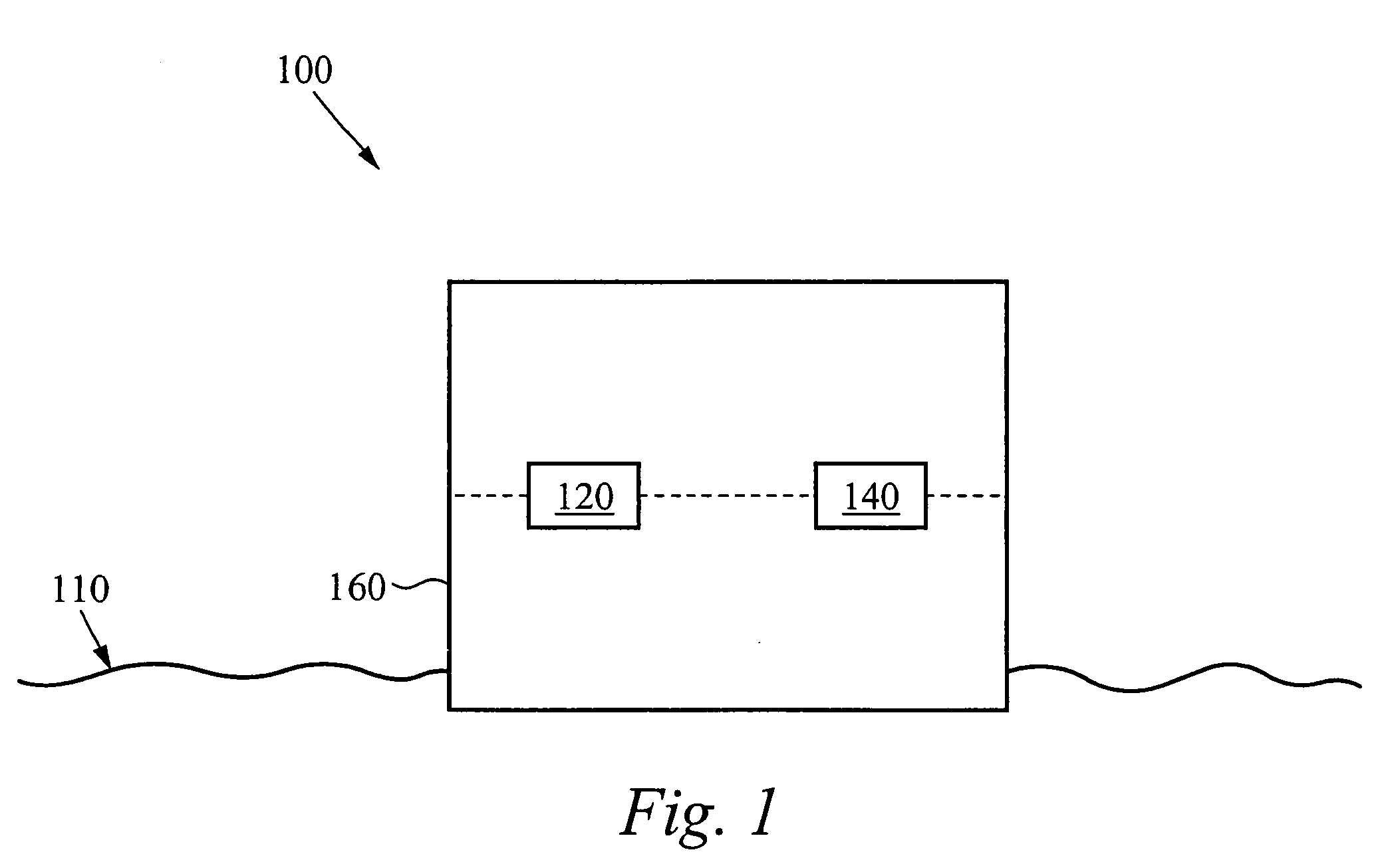

In-situ water analysis method and system

ActiveUS20060292043A1Improve securityImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesWaterborne vesselsProcess chemistryAnalysis method

An automatic system for monitoring chemistry information for a body of water comprises a sensor for determining chemistry information, a microprocessor for processing chemistry information, and a housing coupled to at least one of the sensor and the microprocessor. Preferably the housing is floatable or mountable. The method of providing chemistry information of a body of water comprising the steps of obtaining a sample of the body of water and determining chemistry information.

Owner:HITEK AQUA SYST

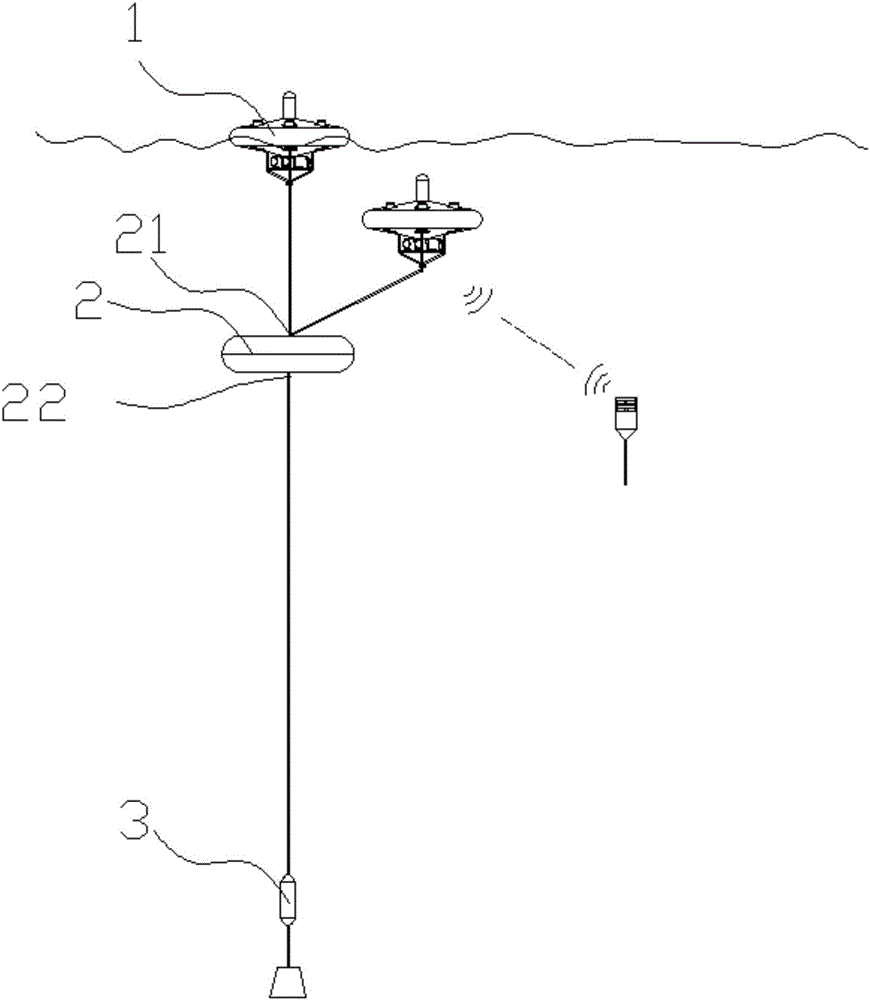

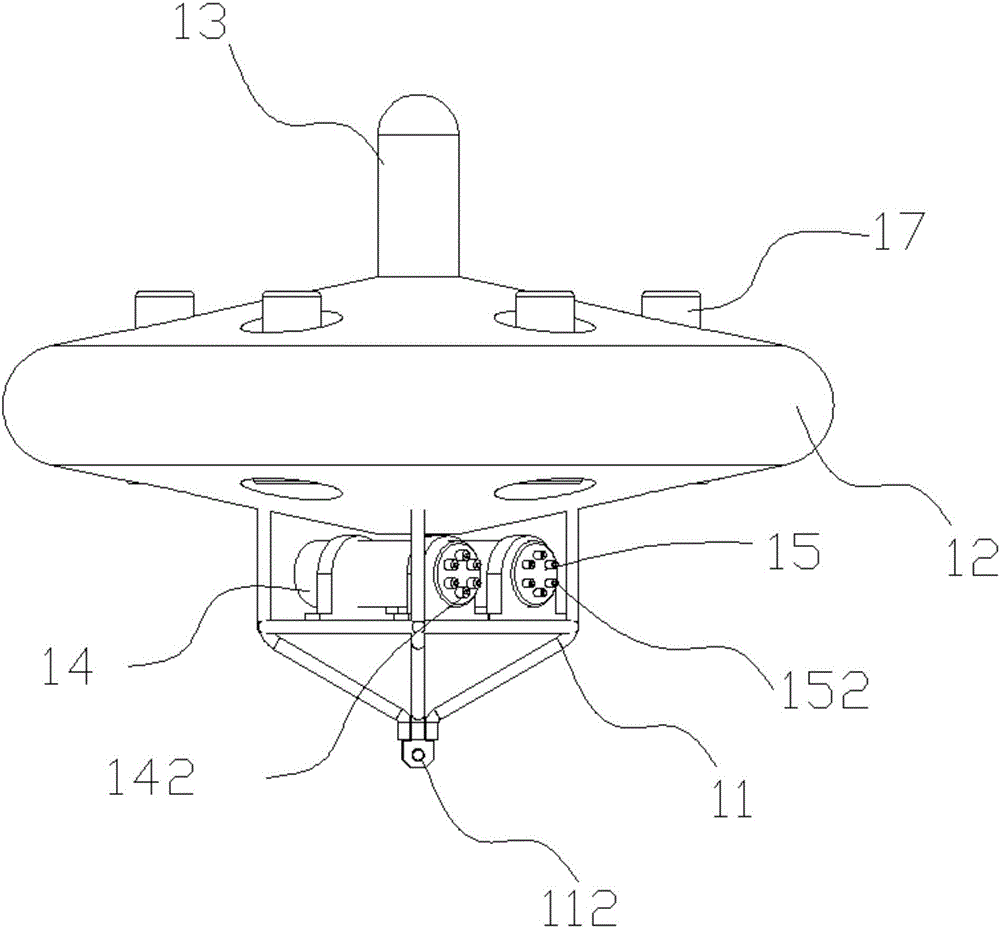

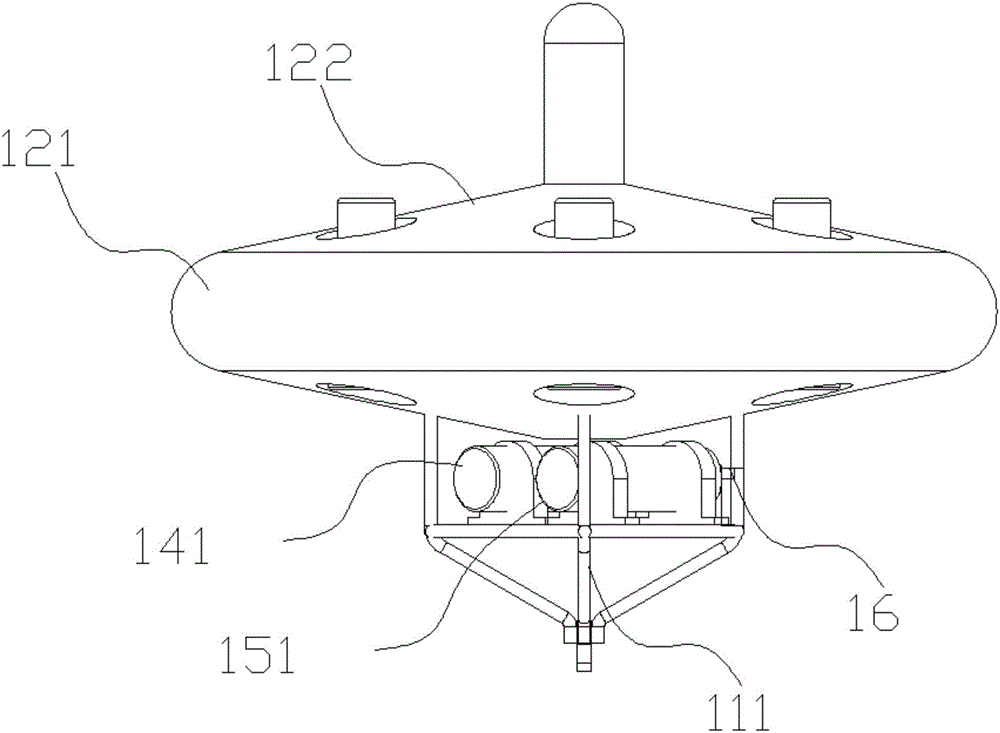

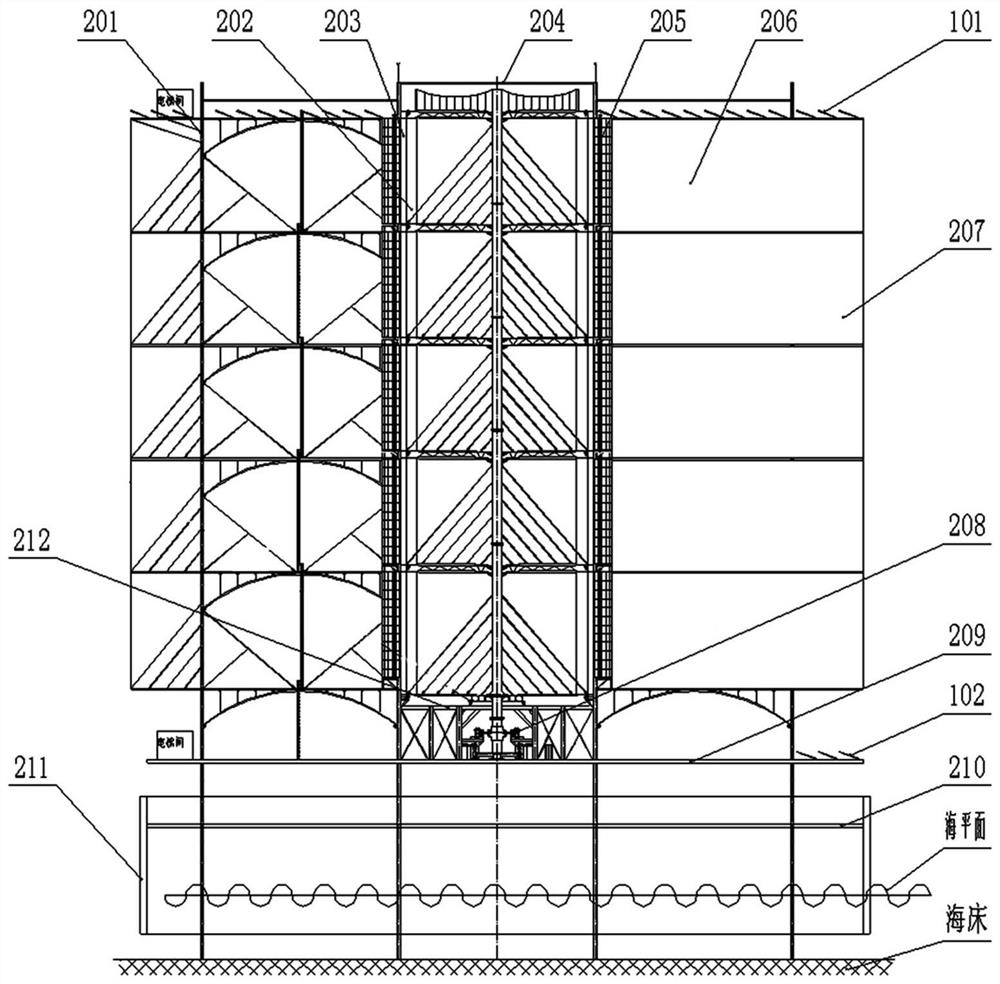

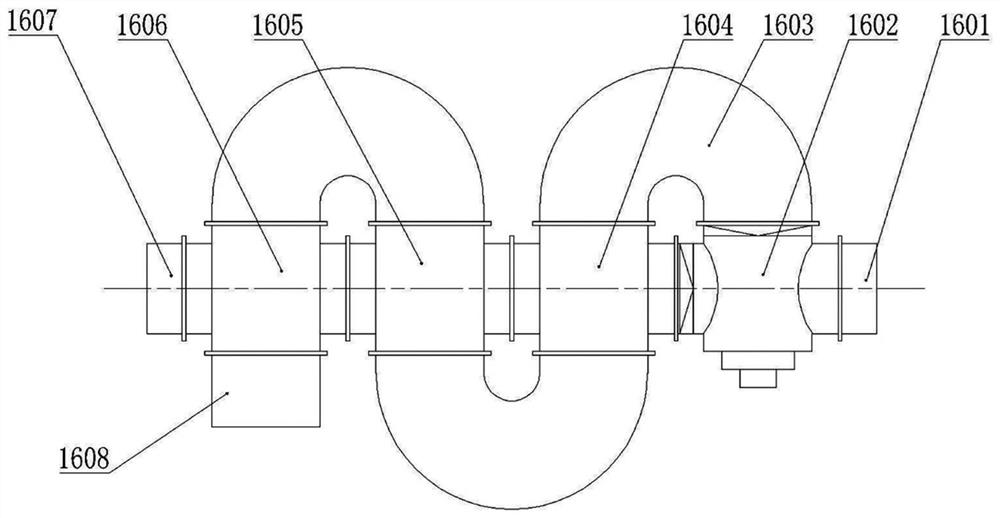

Buoyancy-driven intelligent self-lifting communication subsurface buoy system

The invention discloses a buoyancy-driven intelligent self-lifting communication subsurface buoy system which comprises an intelligent self-lifting communication floating body, a main floating body and an anchoring system. The intelligent self-lifting communication floating body comprises a main frame, a floating body material, a communication antenna, an electronic compartment, a battery compartment, an acoustic module and a buoyancy-driven adjusting mechanism. The buoyancy-driven intelligent self-lifting communication subsurface buoy system has the advantages that the subsurface buoy system can realize real-time transmission of data of a subsurface buoy, so that timeliness of the data is guaranteed; switching of a working state of a mechanism around a density jumping layer is realized by cooperation of the buoyancy-driven adjusting mechanism and a control system, long-term working capability of the surface buoy system at low power consumption is realized, floating motion and a communication function under low ocean current are realized, overall power consumption of the subsurface buoy system is lowered, and working cycle of the subsurface buoy system is prolonged greatly; by being controlled to float and dive, the communication subsurface buoy is effectively protected from being damaged by organisms or ships on the sea, and high working reliability of the subsurface buoy is guaranteed.

Owner:INST OF DEEP SEA SCI & ENG CHINESE ACADEMY OF SCI

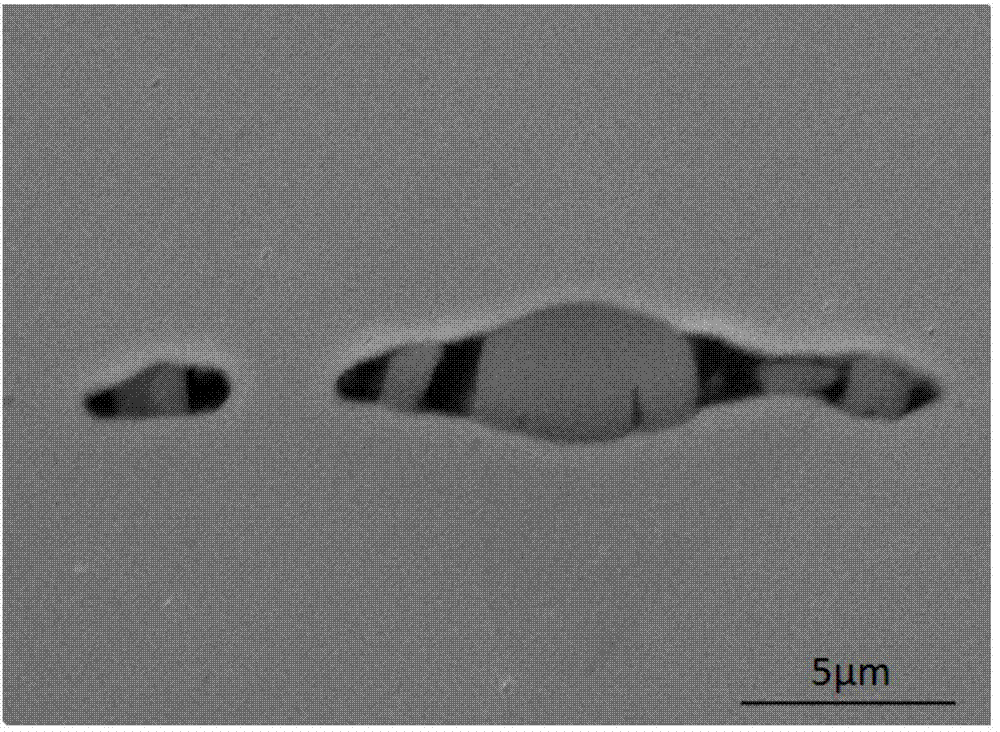

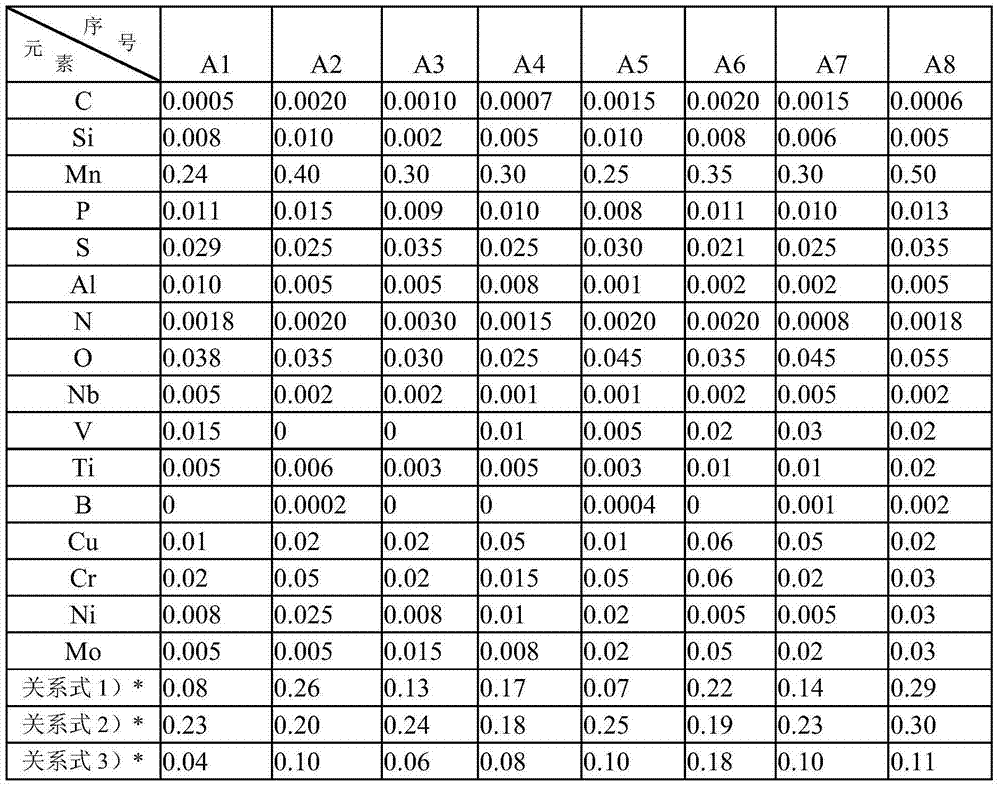

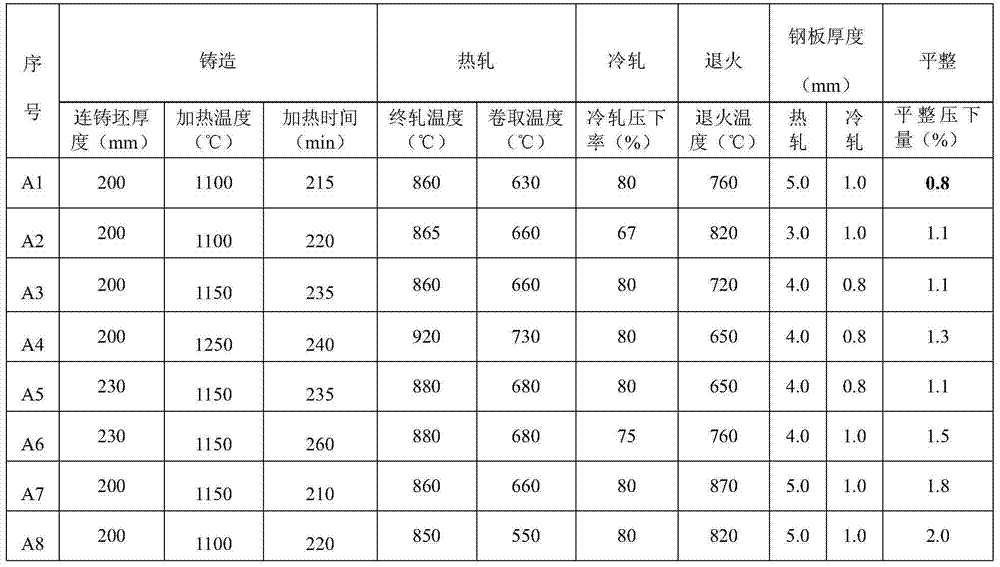

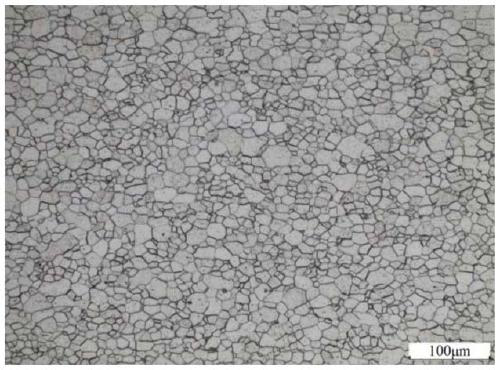

Enamel steel sheet for direct glazing and manufacturing method thereof

ActiveCN104775069AGood formabilityReduce timelinessProcess efficiency improvementSheet steelChemical element

The invention discloses an enamel steel sheet for direct glazing, which comprises the following chemical elements in percentage by mass: 0.0005-0.002% of C, 0.24-0.50% of Mn, 0.021-0.035% of S, 0.025-0.055% of O, at most 0.010% of Si, at most 0.015% of P, at most 0.010% of Al, at most 0.003% of N, and the balance of Fe and other inevitable impurities, wherein 0<=Mn-1.7*O+3.4*S<=0.30%, and 2.7*O+4.4*S>=0.14%. The invention also discloses a manufacturing method of the enamel steel sheet for direct glazing, which comprises the following steps: (1) molten iron pretreatment; (2) smelting and refining; (3) casting; and (4) hot rolling. The enamel steel sheet for direct glazing has excellent surface characteristics and favorable inherent quality.

Owner:BAOSHAN IRON & STEEL CO LTD

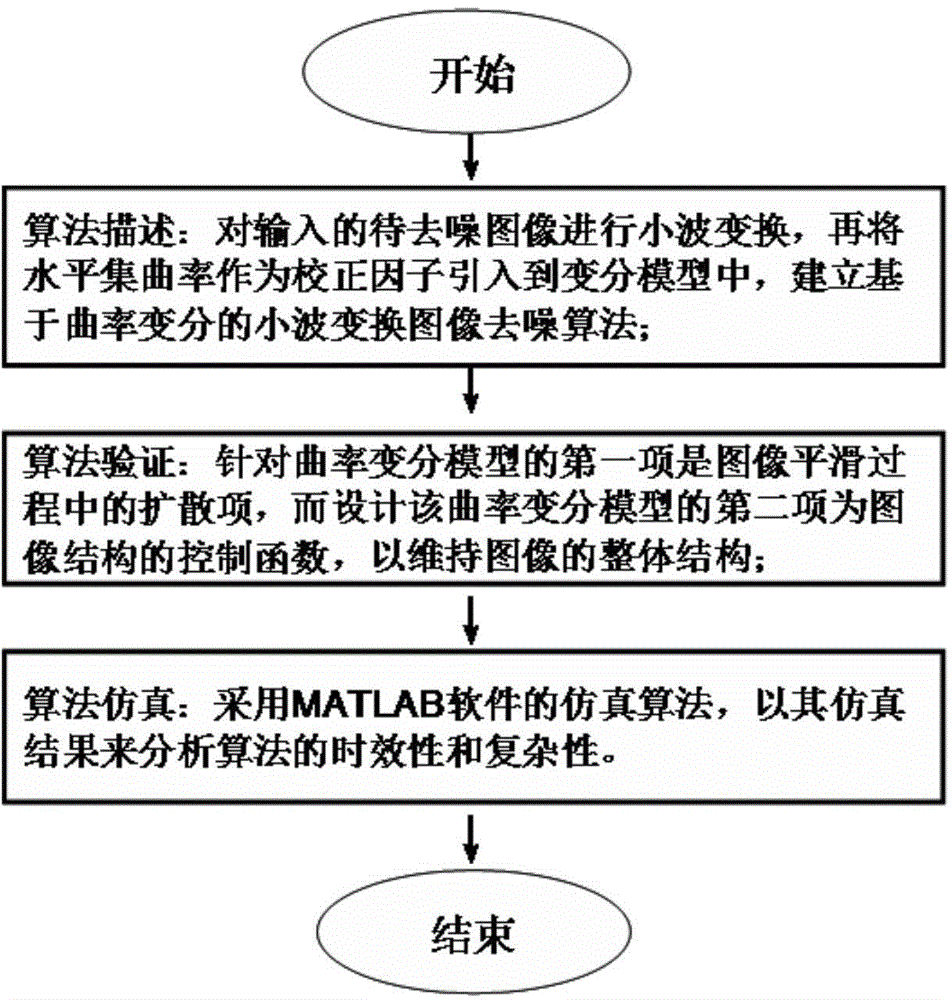

Curvature variation based wavelet image denoising algorithm

ActiveCN104616249AReduce complexityReduce the amount of informationImage enhancementDenoising algorithmAlgorithm

The invention relates to a curvature variation based wavelet image denoising algorithm. The curvature variation based wavelet image denoising algorithm is characterized by comprising the steps of 1, algorithm description, namely, performing wavelet transformation for an input image to be denoised, introducing a horizontal set curvature as a correction factor into a variation model, and creating the curvature variation based wavelet image denoising algorithm; 2, algorithm verification, namely, the first item for the curvature variation model is a dispersion item in the image smoothing process, and the second item of the curvature variation model is designed to be the control function of the image structure, to maintain the integral structure of the image; 3, algorithm simulation, namely, performing the simulation algorithm of MATLAB software, and analyzing the timeliness and complexity of the algorithm through the simulation result. With the adoption of the algorithm, the processed image can be clear and close to the original image; the signal to noise of the denoised image is increased by about 15dB by being compared with that of a TV model; the classic wavelet threshold denoising algorithm is increased by about 25dB, and moreover, the definition is greatly improved.

Owner:江苏明天互联网大健康科技有限公司

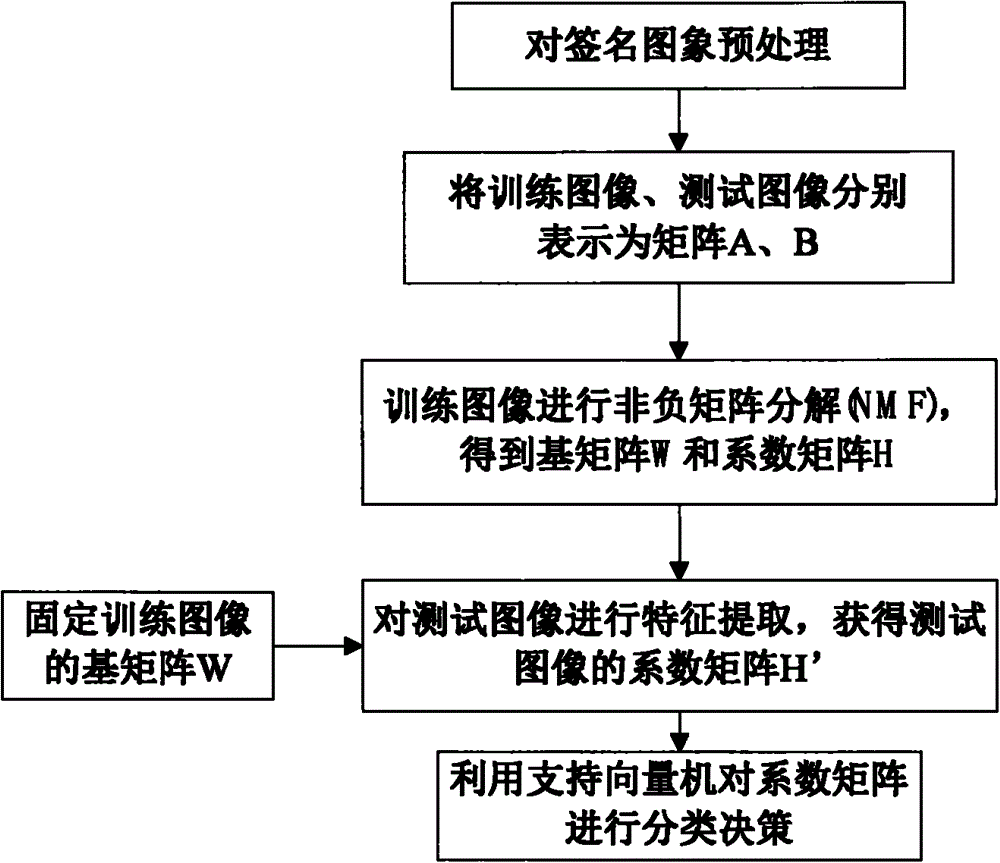

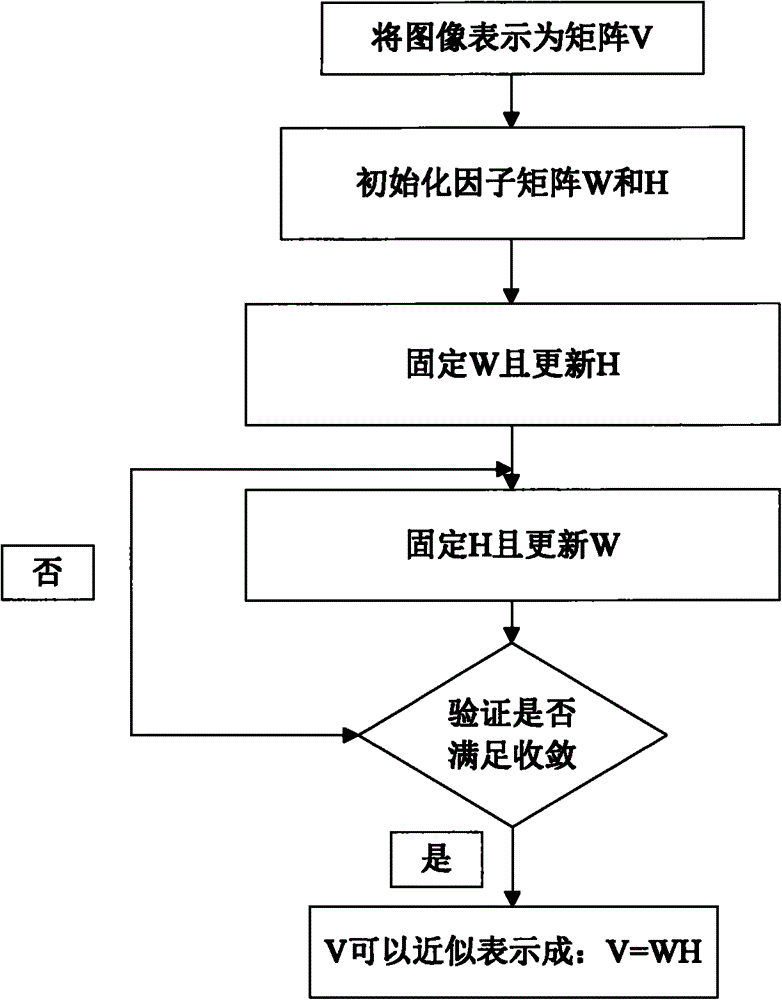

Off-line handwritten signature recognition method based on non-negative matrix factorization

InactiveCN104463084AReduce timelinessCharacter and pattern recognitionSupport vector machineFeature vector

The invention discloses an off-line handwritten signature recognition method based on non-negative matrix factorization (NMF). The method comprises the needed steps that 1, signature data are collected, all signature images are preprocessed, and a data matrix A of all preprocessed training set signature images and a data matrix B of testing set signature images needing recognizing are obtained; 2, features of the training set signature images are extracted, wherein NMF is performed on the A, and a corresponding base image matrix W and a feature matrix H formed by weight vectors which are namely the feature vectors and correspond to all the signature images are obtained; 3, features of the testing set signature images are extracted, wherein the data matrix B of the testing set signature images are projected on a base image, and a projection coefficient matrix H' is obtained; 4, training and classification decision are carried out through a support vector machine, and whether the signature is true or false is judged.

Owner:JIANGNAN UNIV

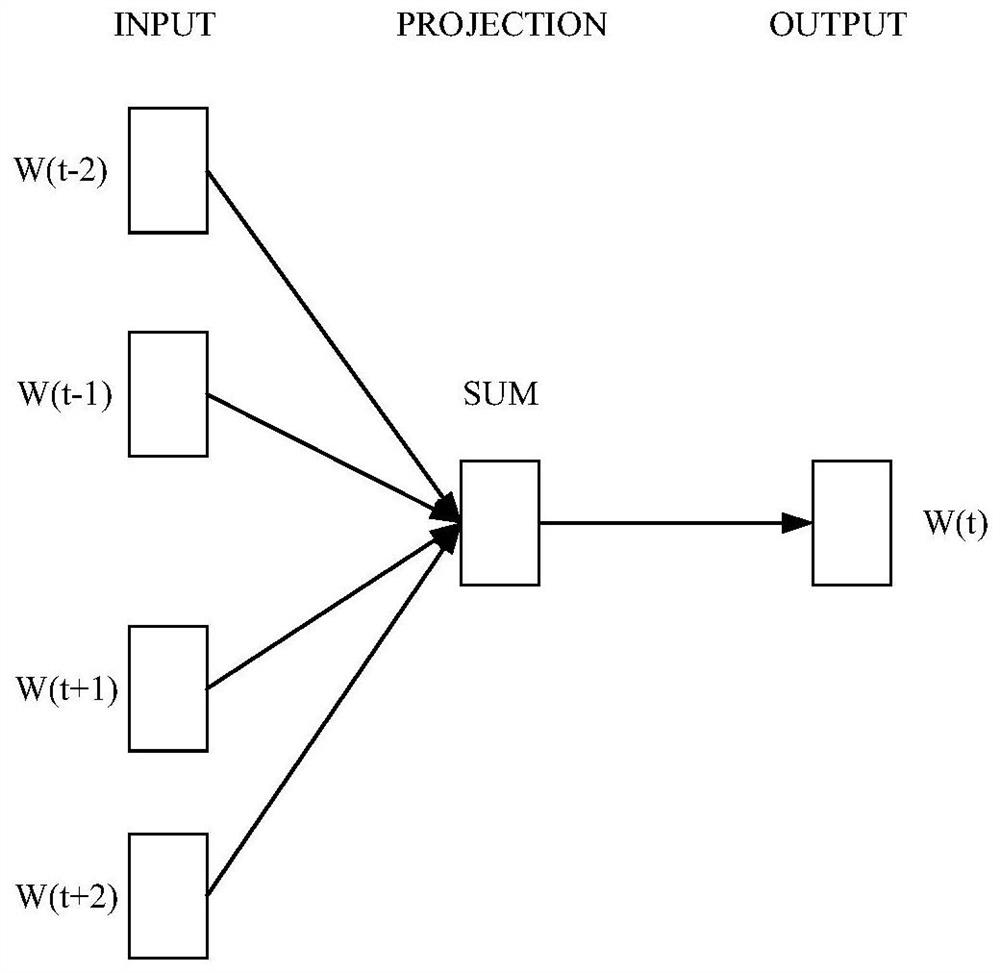

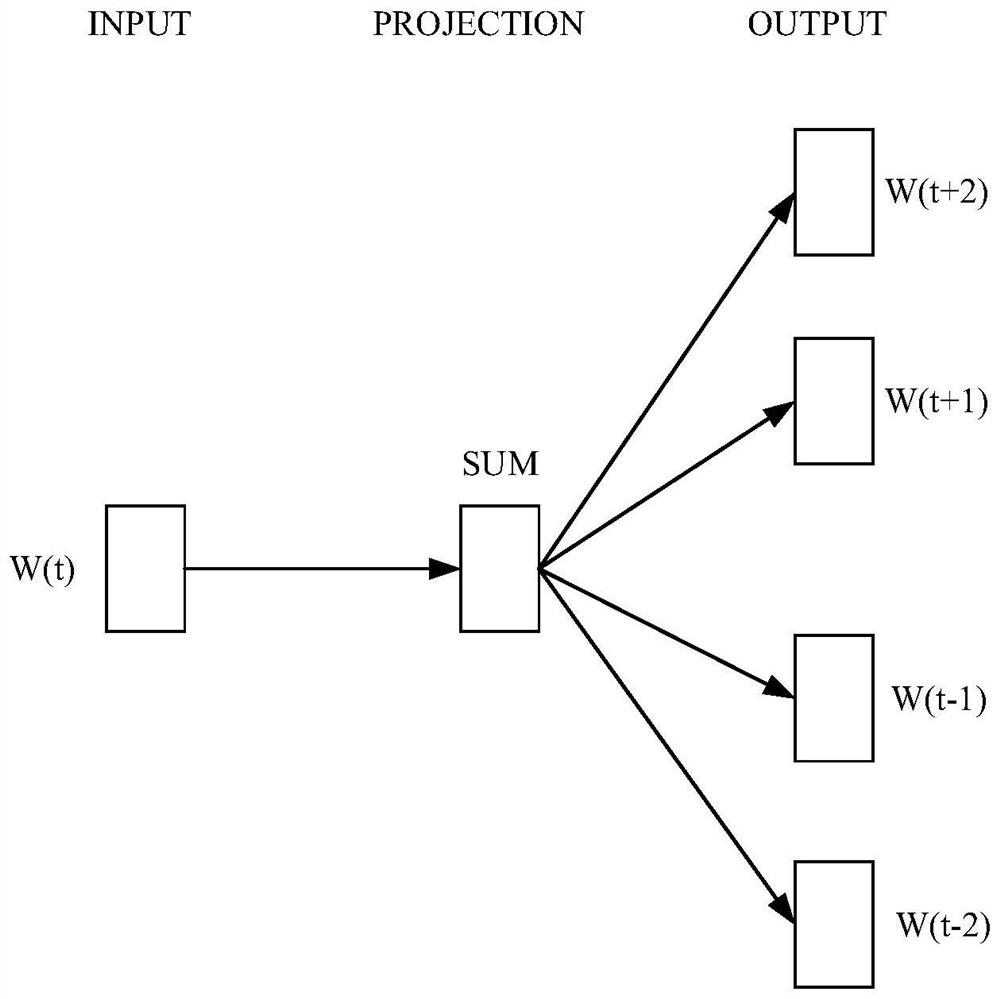

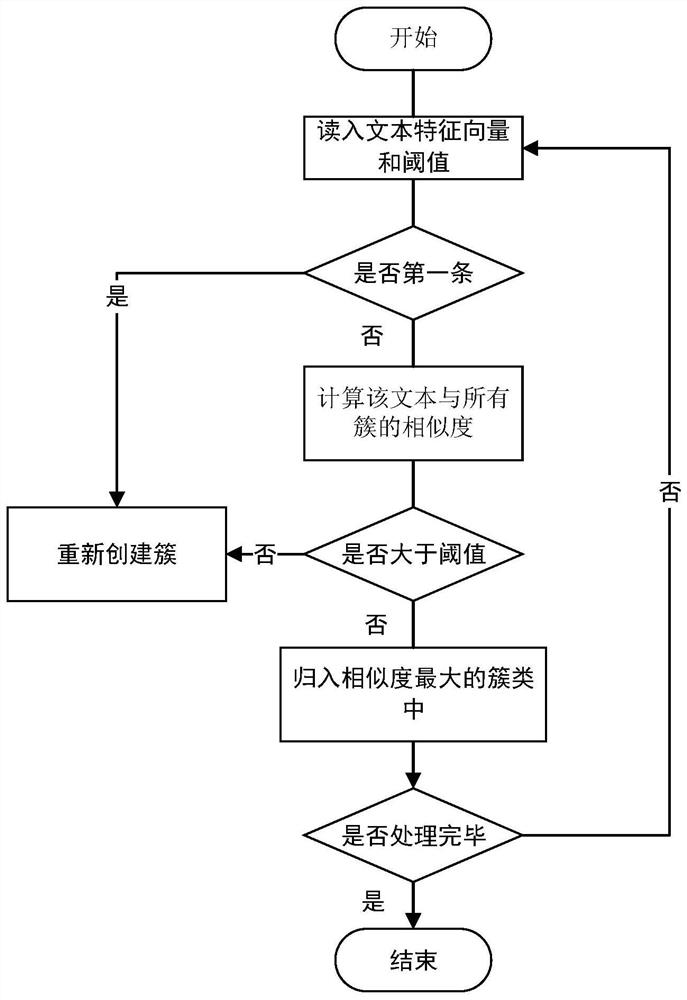

Microblog topic clustering method based on word vector and singe-pass fusion

PendingCN111694958AImprove integrityImprove clustering effectCharacter and pattern recognitionNatural language data processingCluster algorithmWord list

The invention discloses a microblog topic clustering method based on word vector and single-pass fusion. The method comprises the steps of: preprocessing obtained microblog data, and constructing a word list library; carrying out Word2vec word vector mapping on the feature words; clustering microblog texts by adopting a single-pass fused with Word2vec word vectors; and performing topic discovery on the clustering cluster by using an LDA topic model. According to the method, text deep semantic information can be effectively mined on the basis of a single-pass incremental clustering algorithm fused with Word2vec word vectors, it can be avoided that the VSM dimension is too high to influence the computer processing speed, and meanwhile the problem that distribution of feature words among classes and distribution of the feature words in documents inside the classes are ignored in a traditional TF-IDF statistical method is effectively solved.

Owner:深兰人工智能应用研究院(山东)有限公司

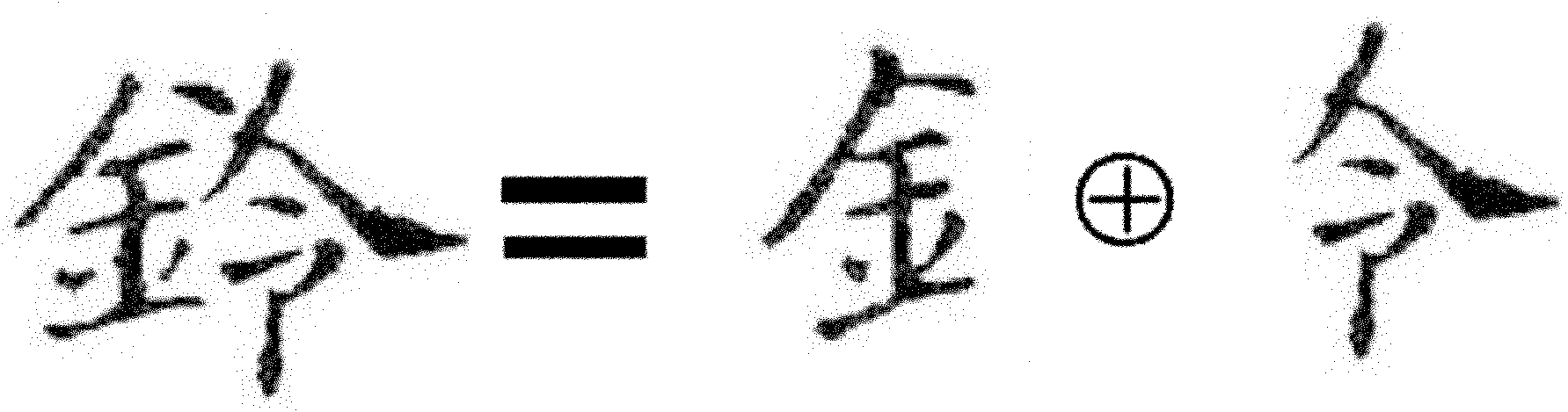

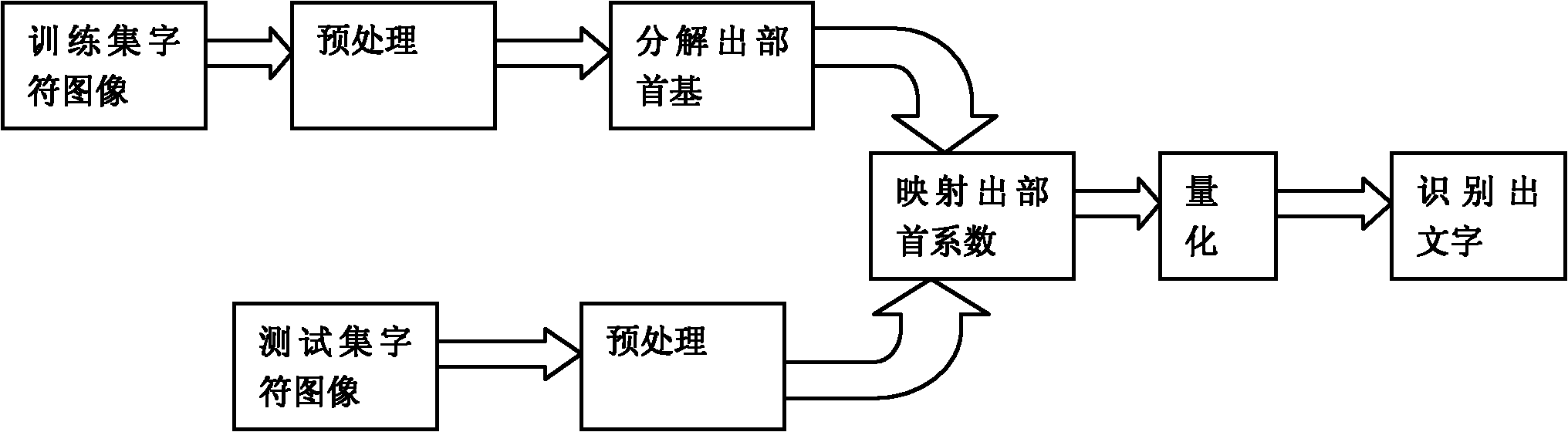

Off-line Chinese character identification method on basis of non-negative matrix factorization

InactiveCN102073871AReduce timelinessImprove efficiencyCharacter and pattern recognitionChinese charactersNonnegative matrix

The invention discloses an off-line Chinese character identification method on the basis of non-negative matrix factorization, which comprises the following steps of: carrying out preprocessing on each character image in training set character images and testing set character images which need to be identified so that characters are positioned at the centered positions of the corresponding character image; carrying out non-negative matrix factorization of a character set vector on the preprocessed training set character images to obtain a radical base; carrying out projection on the preprocessed testing set character images on the radical base and obtaining projection coefficients; and identifying corresponding words of the characters in each character image in the testing set character images according to the projection coefficients. The method utilizes shape characteristics and radical characteristics of Chinese characters to realize higher efficiency character identification by a method of carrying out factorization on radicals of the Chinese characters.

Owner:广州市伟时信息系统技术有限公司 +1

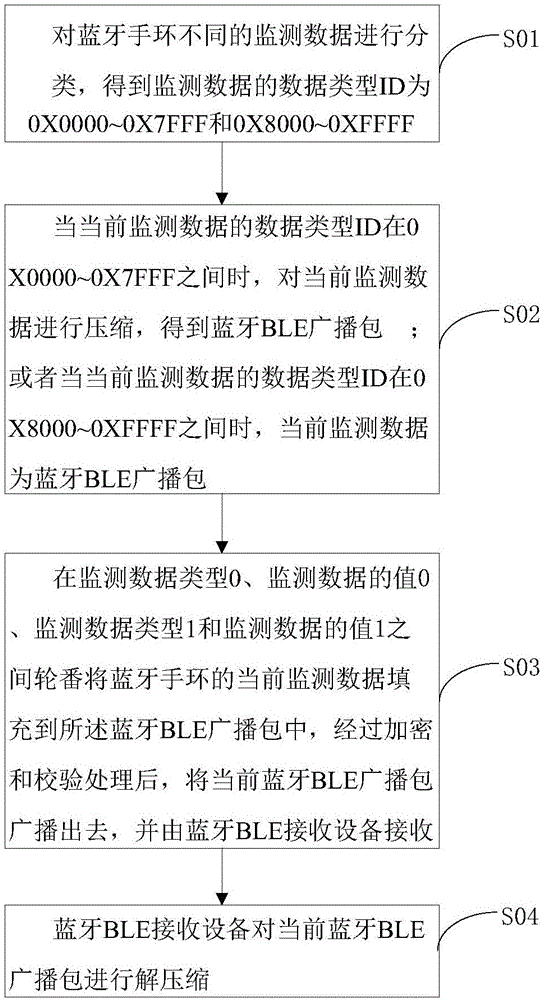

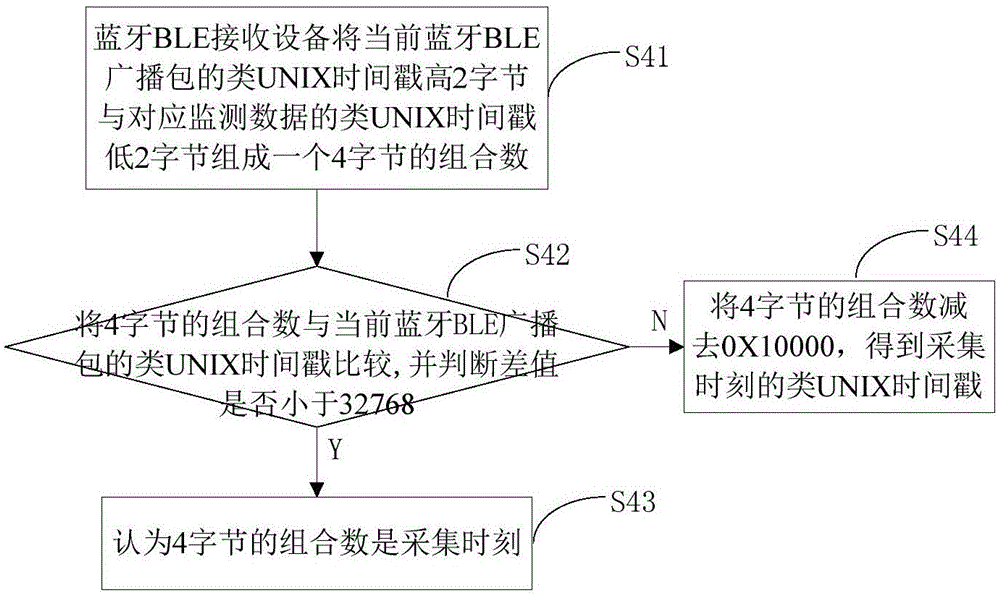

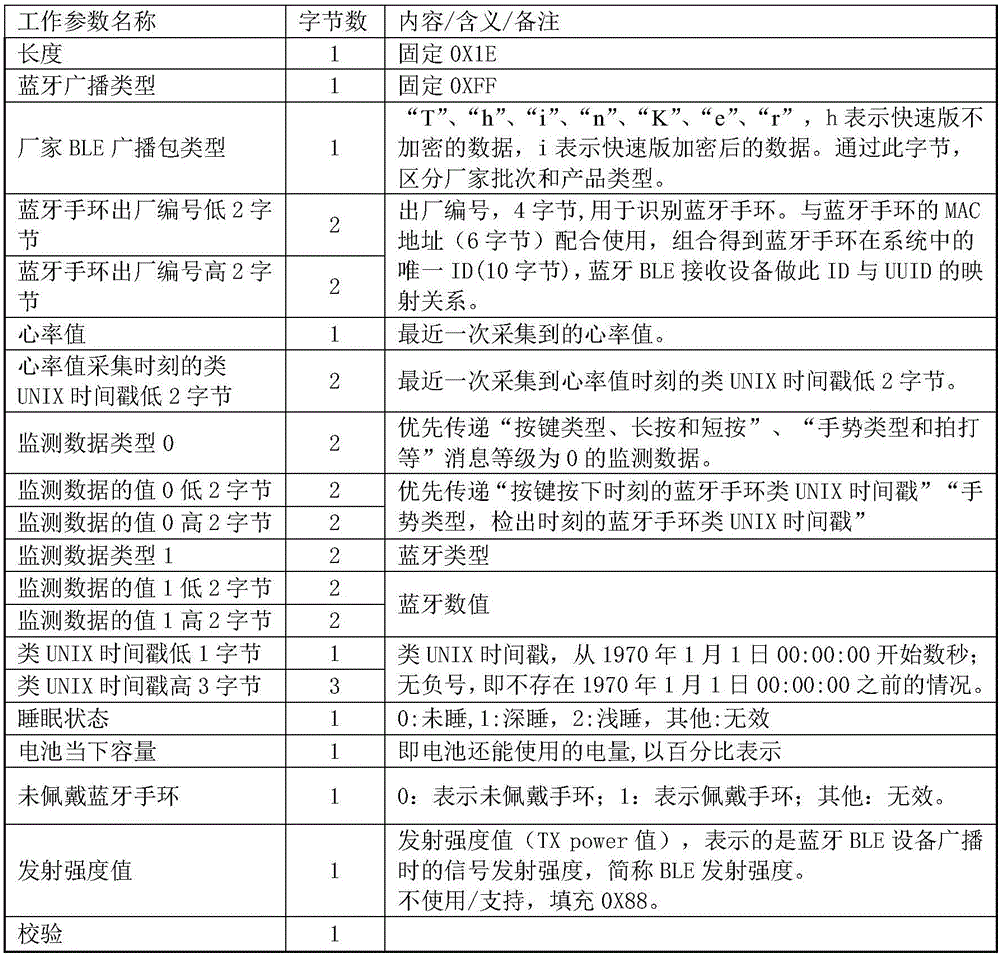

Method and device for broadcasting monitoring data of Bluetooth wristband

ActiveCN106507272AEasy to removeReduce data trafficBroadcast service distributionWireless commuication servicesBroadcast packetUnix

The invention discloses a method and device for broadcasting a Bluetooth wristband. The method includes classifying the monitoring data of the Bluetooth wristband to obtain a data type ID; when the data type ID is between 0X0000 and 0X7FFF, compressing the monitoring data to obtain a Bluetooth BLE broadcast packet, wherein 2 lower bytes of the Bluetooth BLE broadcast packet are actual values, and 2 higher bytes are 2 lower bytes of a UNIX-like timestamp at the moment when the actual values are acquired; and filling the current monitoring data to the Bluetooth BLE broadcast packet in turn among the monitoring data type 0, the value 0 of the monitoring data, the monitoring data type 1 and the value 1 of the monitoring data, broadcasting after encryption and verification, and receiving by Bluetooth BLE receiving device. The method for broadcasting the monitoring data of the Bluetooth wristband can efficiently transmit current state data of the Bluetooth wristband, while the Bluetooth wristband location information and current data are effectively obtained, the capacity of system access is improved, data flow between a device and the BLE receiving device is reduced, and repetitive operation is avoided.

Owner:广州创想云科技有限公司

A NAND Flash solid state storage adaptive error control method

ActiveCN109087683AReliable recoverySolve bottlenecksStatic storageSolid-state storageComputer architecture

A NAND-type flash solid-state storage adaptive error control method includes dividing the data to be stored into groups according to the length of each page of NAND Flash structure before the data isstored in solid state memory, encoding the data according to the constructed encoder, storing the encoded code word in data area according to page, and storing the check bit information in ECC area ofcorresponding page. When reading out data, the data read out by page is decoded by the high-efficiency error-correcting hard data decoding module. If the decoding is successful in a reasonable numberof iterations, the decoding result is output for reading and error-correcting of the next page of data. If the hard data decoding fails or cannot be completed within a reasonable number of iterations, the data recovery soft information decoding is called for data recovery processing at the expense of reducing the timeliness. The invention has the advantages of reliably recovering the high bit error rate data and avoiding the loss of important data.

Owner:SAGE MICROELECTRONICS CORP

Cold rolled thin steel strip for battery shell and production method thereof

The invention discloses a cold rolled thin steel strip for a battery shell and a production method thereof. The cold rolled thin steel strip is prepared from the following chemical components in percent by mass: 0.006-0.009% of C, 0.20-0.45% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.015% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, 0.030-0.045% of Als, 0.030-0.045% of Ti and the balance Fe and inevitable impurities. The cold rolled thin steel strip disclosed by the invention has the advantage that the steel strip is reasonable in proportion of alloy components, relatively low in cost, good in forming performance and excellent in surface quality.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

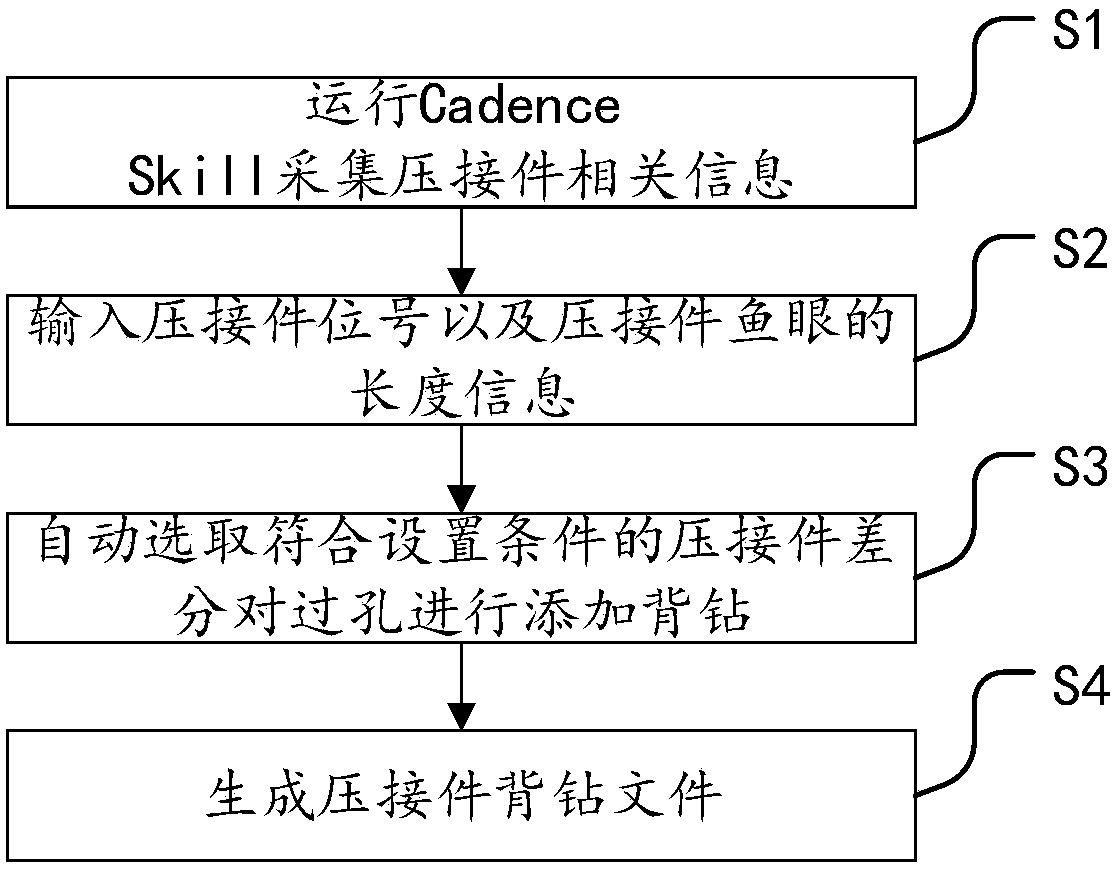

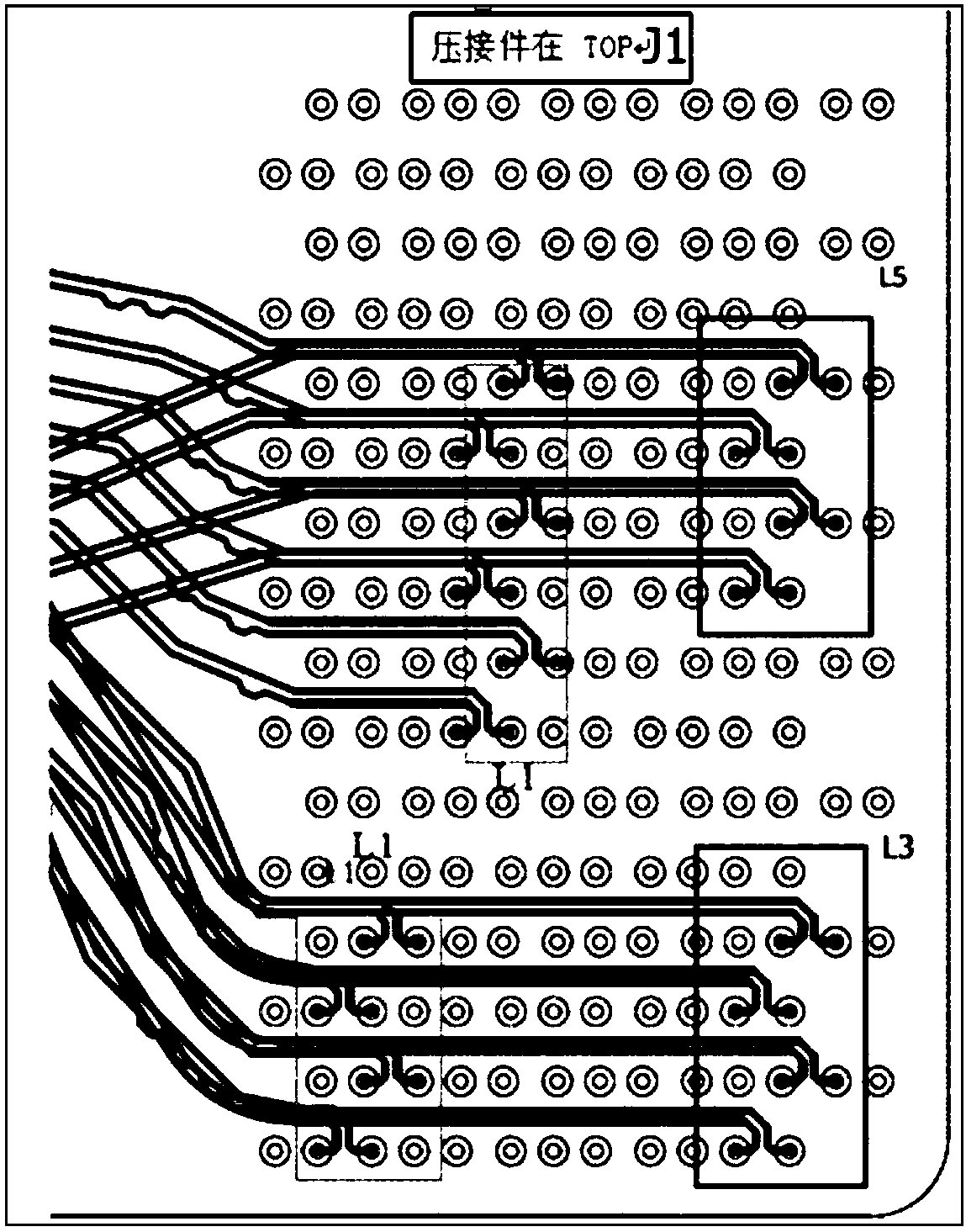

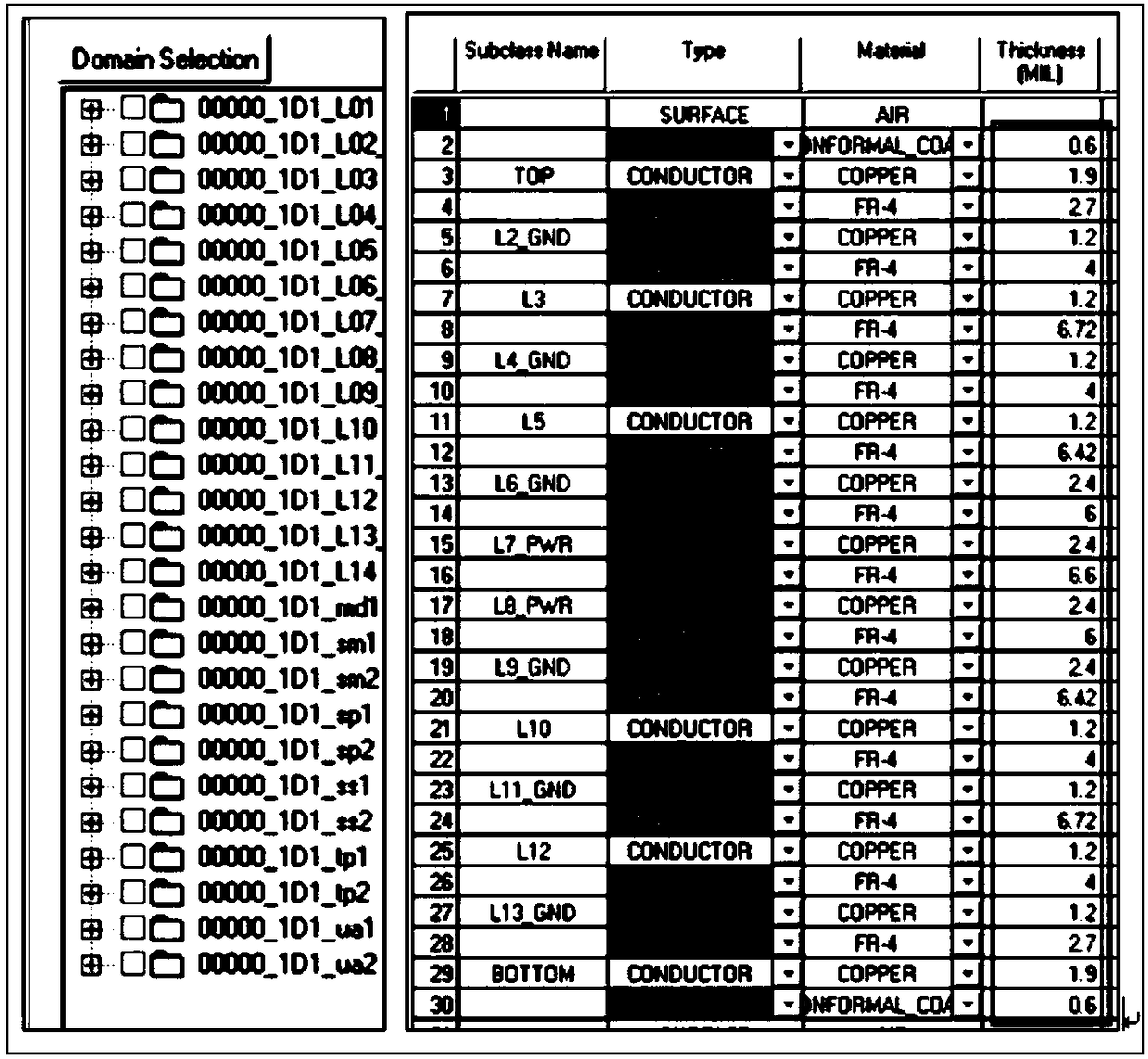

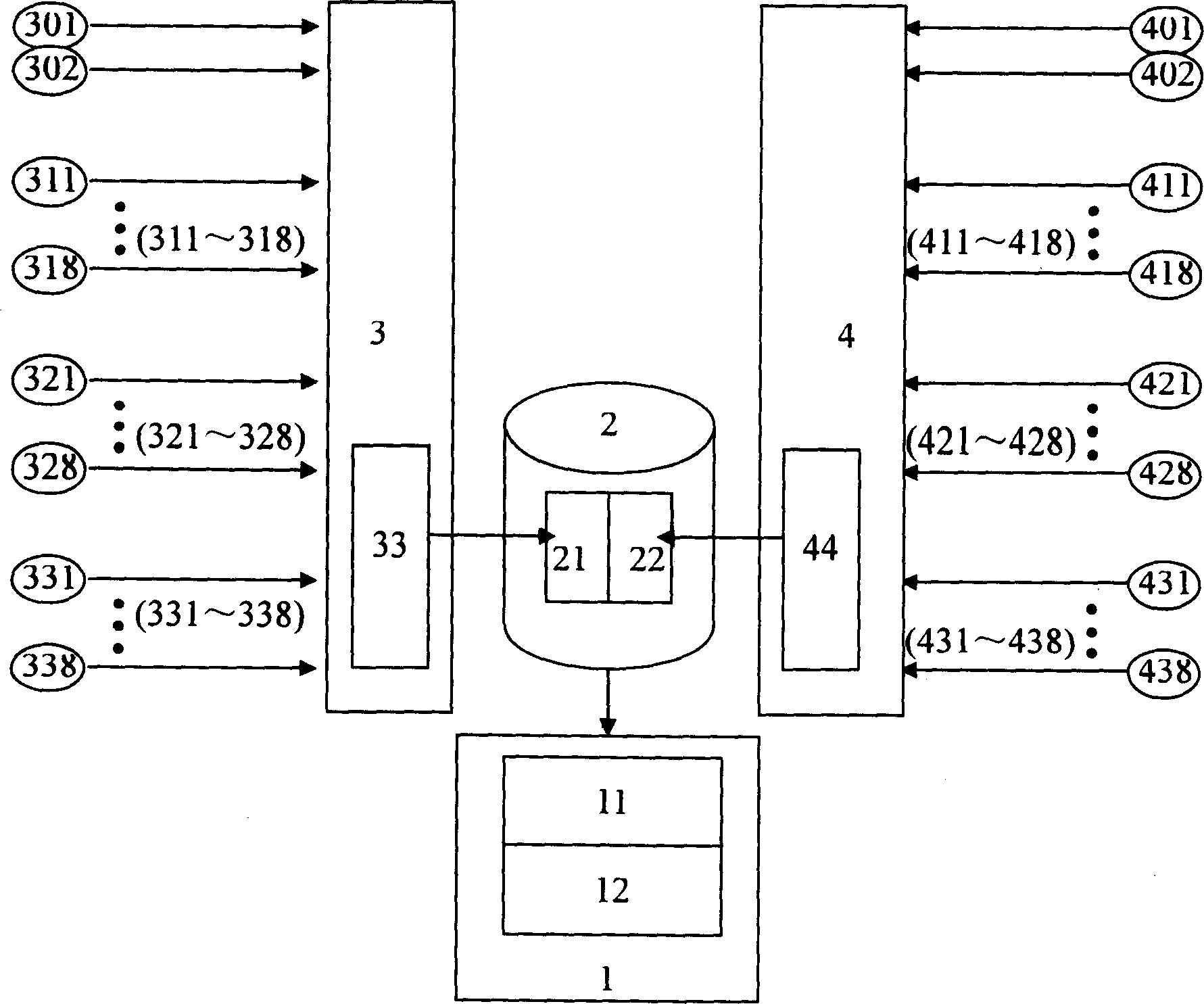

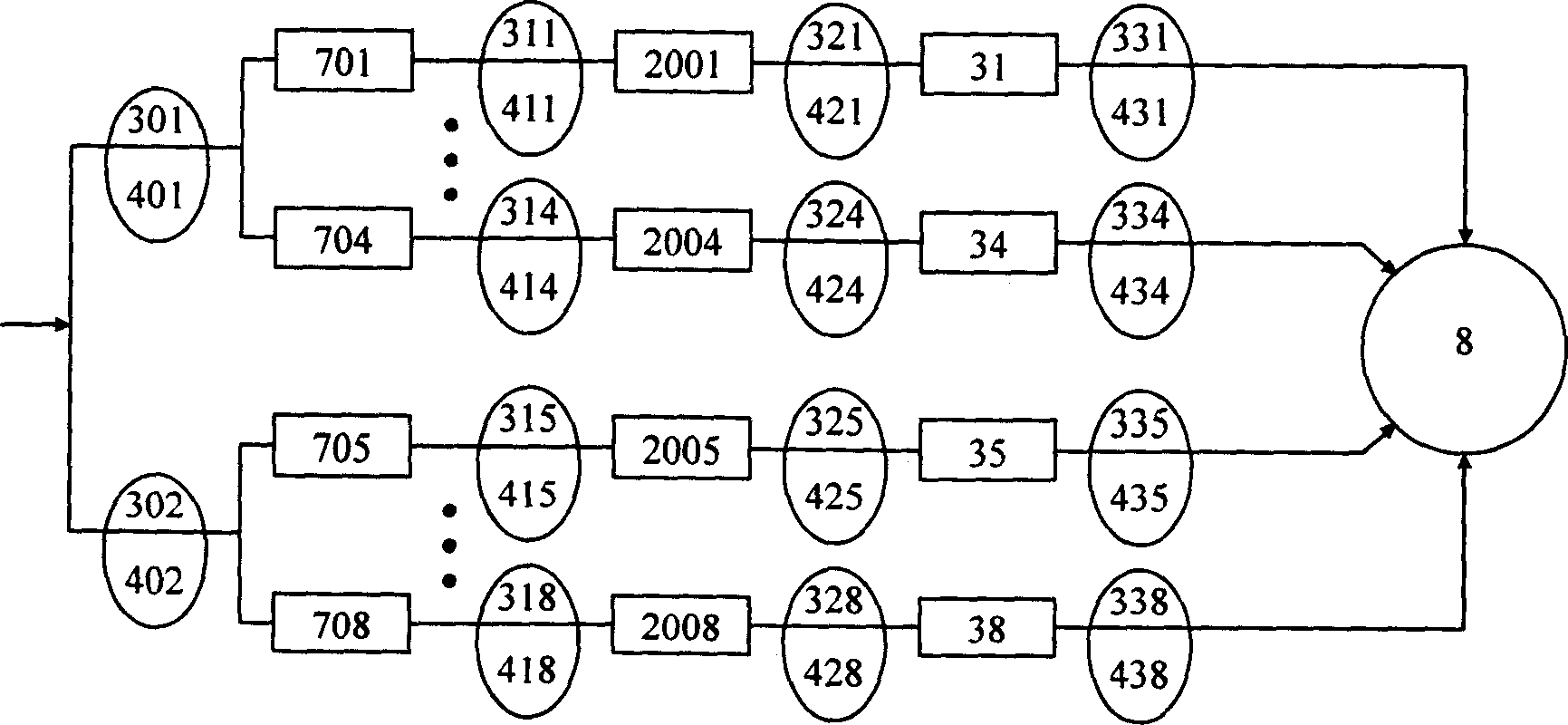

Generation method and system for pressure welding element backdrill via hole file on the basis of Cadence Skill

ActiveCN108595839AQuality improvementImprove accuracySpecial data processing applicationsRelevant informationBit numbering

The invention provides a generation method and system for a pressure welding element backdrill via hole file on the basis of Cadence Skill. The method comprises the following steps that: S1: operatingthe Cadence Skill to collect the relevant information of a pressure welding element; S2: inputting a pressure welding element bit number and the length information of a pressure welding element fisheye; S3: automatically selecting a pressure welding element difference which conforms to a set condition to add a backdrill to the via hole; and S4: generating the pressure welding element backdrill via hole file. By use of the method, the problems of large workload and low design efficiency since a great quantity of backdrill information needs to be confirmed for multiple times when a PCB (PrintedCircuit Board) factory carries out backdrill can be solved, design efficiency is improved, the problems of drilling missing and excessive drilling when the PCB factory caries out the backdrill can beavoided, the design accuracy of an engineer is improved, information confirmation timeliness is greatly shortened, and quality generated when the PCB factory beat boards can be effectively improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Manufacturing method of automobile speed changing box alloy gear shaft

InactiveCN105296889AReduce timelinessLow Al contentFurnace typesHeat treatment furnacesAlloy elementDirect reading

The invention discloses a manufacturing method of an automobile speed changing box alloy gear shaft. The method comprises the following steps: controlling the weight percent of chemical components of various elements in molten steel to meet the following requirements: 2.3 to 2.5 percent of C, 1.2 to 1.4 percent of Mn, 1.6 to 1.9 percent of Cr, 1.2 to 1.5 percent of Si, 0.3 to 0.6 percent of Mg, 0.016 to 0.044 percent of P, 0.38 to 0.52 percent of Ni, 0.015 to 0.025 percent of B, 0.22 to 0.34 percent of V, 0.01 to 0.04 percent of Zn, and the balance of Fe. By adopting a specific addition step of the alloy elements, by using a direct-reading spectrum analysis instrument to control the components of molten steel and by adopting an alloy element proportioning scheme, the timeliness of the steel is maximally reduced, the alloy steel has relatively low content of Al, and no adverse impact on the subsequent cold processing is caused.

Owner:HEFEI HAIYUAN MACHINERY

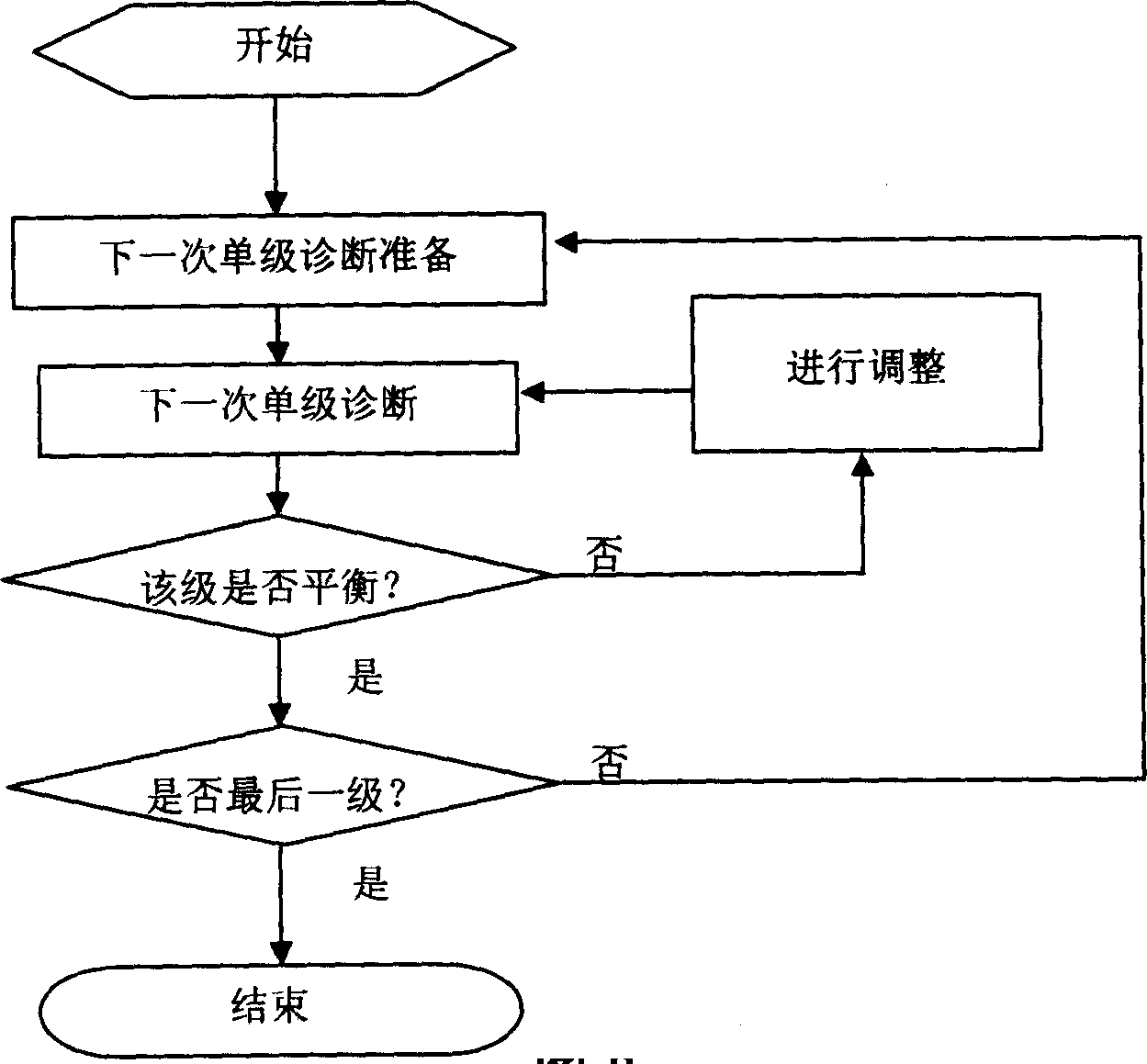

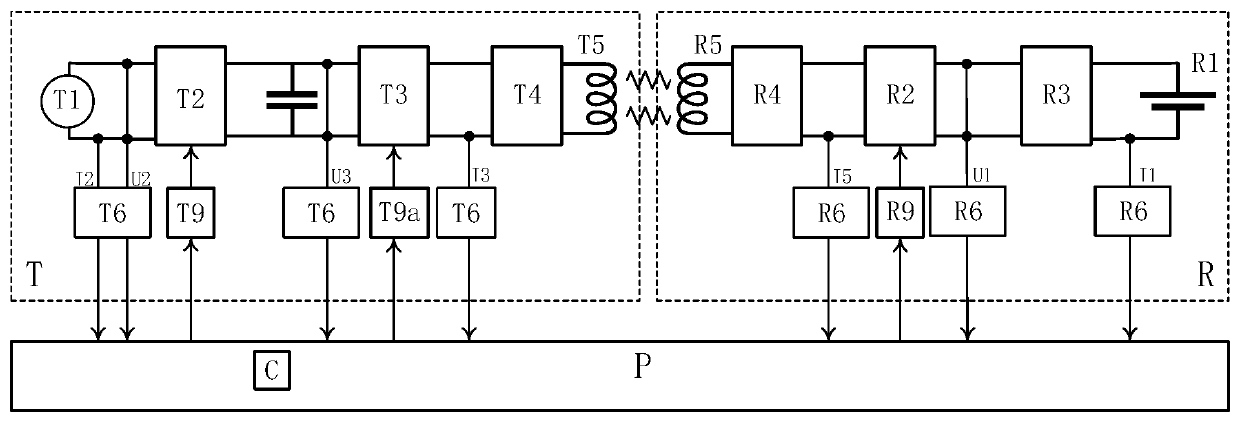

Measuring and processing device for power balance parameter of multipath laser system and power balance method

InactiveCN1821728AReduce timelinessIncrease the difficultyNuclear energy generationPhotometryOptical pathPhysics

This invention relates to a multiple laser systematic balance parameter measurement process device and a method, in which, the device includes: setting testing points of first class, second class and N class at the power balance position reviewed by said multiple laser system, setting a laser energy meter and a waveform collector at the collecting point of each class separately connecting with a computer network, which has an energy collecting software, a waveform collecting software, a data obtaining software and data process software. Said balancing method includes the following steps: automatic collection of energy data and waveform data, data process of them and the power balance diagnosis includes that of energy balance and waveform balance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

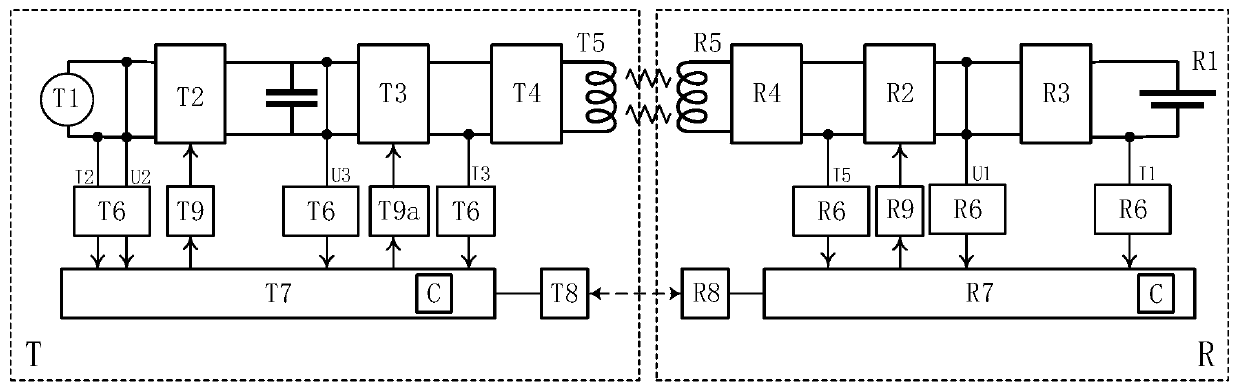

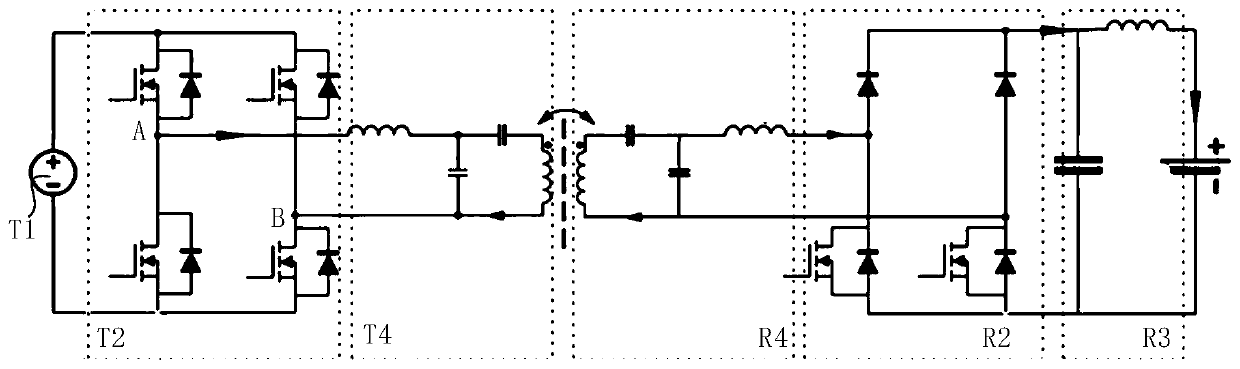

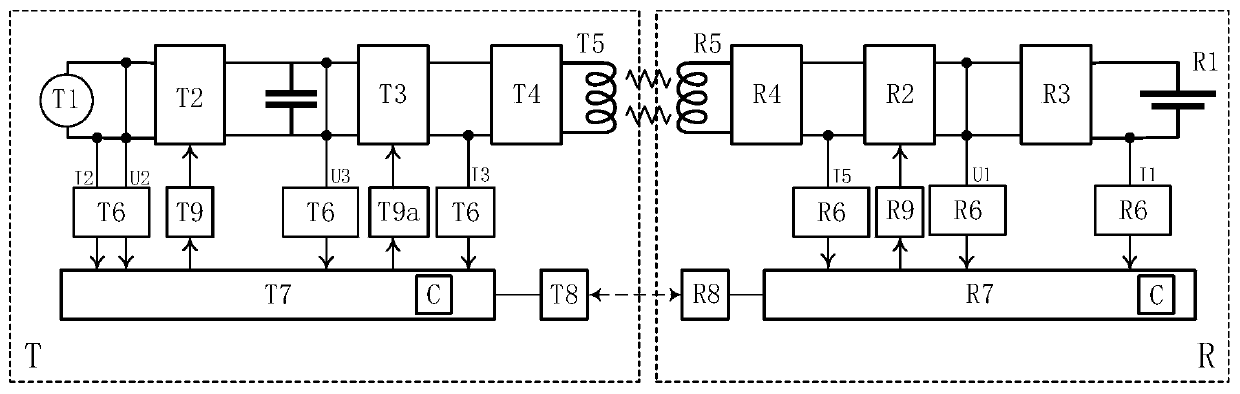

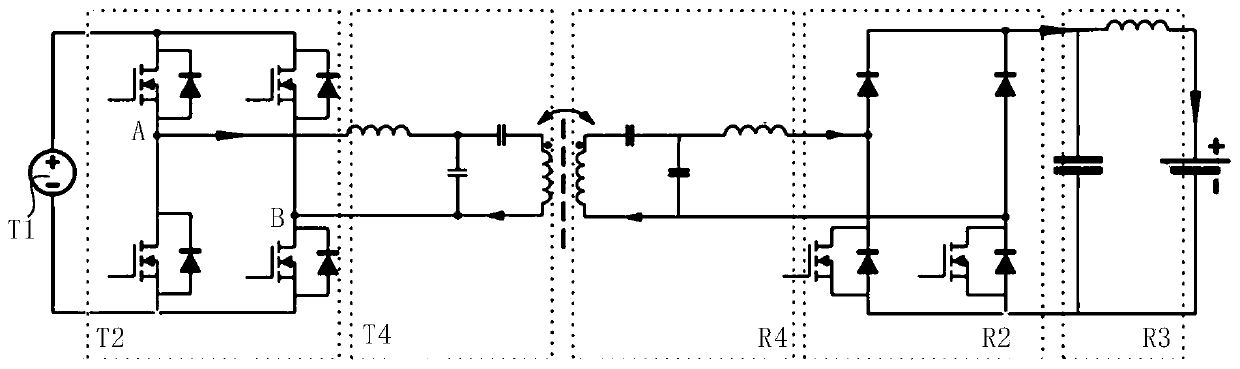

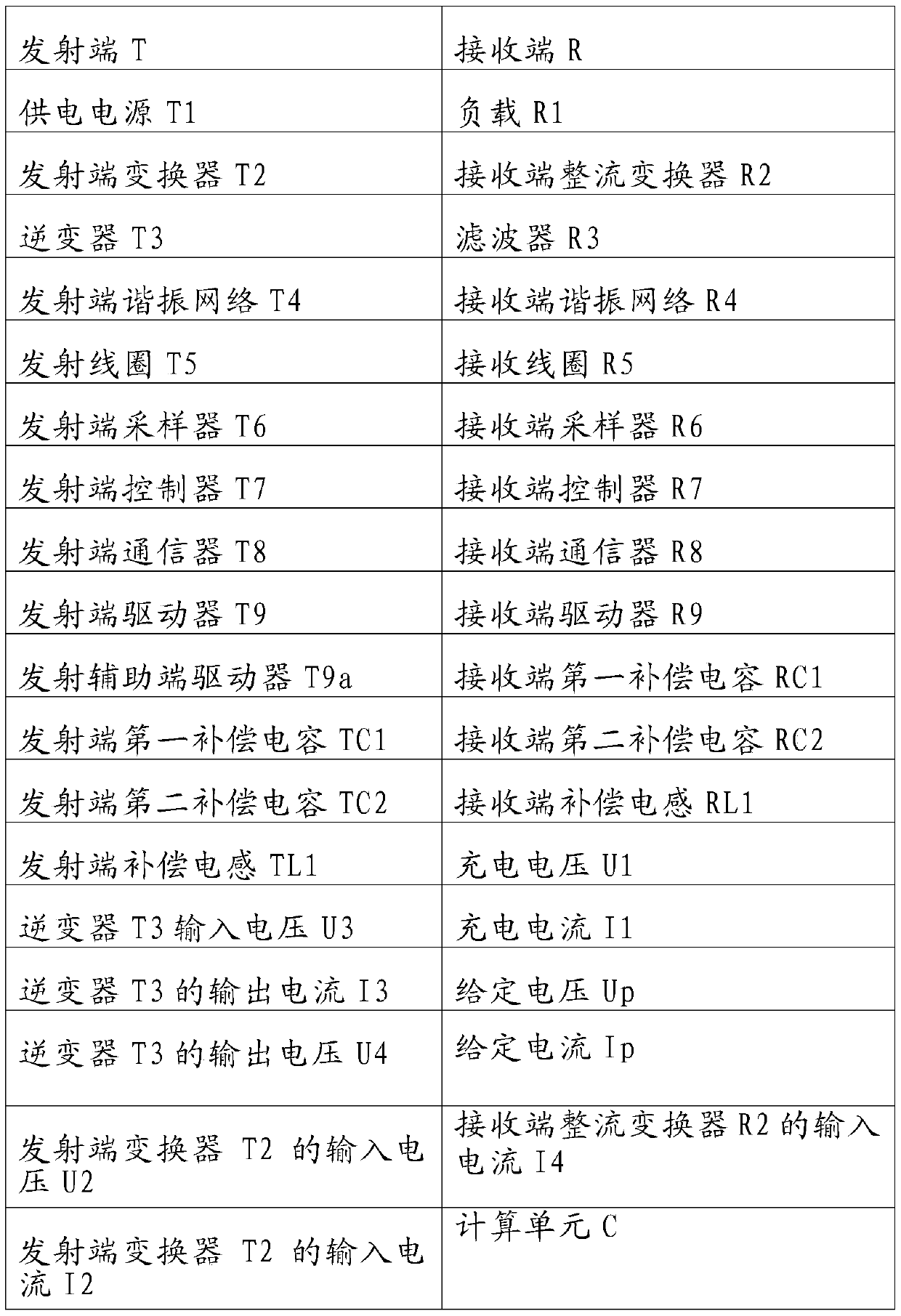

Wireless charging system and wireless charging adjustment method

PendingCN111009972AReduce timelinessHigh adjustment accuracyCharging stationsCircuit arrangementsTelecommunicationsControl theory

The invention discloses a wireless charging system and a wireless charging adjustment method, the wireless charging system comprises a transmitting end and a receiving end, and the transmitting end isprovided with a transmitting end adjustable unit; the receiving end is provided with a receiving end adjustable unit; the wireless charging system further comprises a controller which is respectivelycommunicated with the transmitting end adjustable unit and the receiving end adjustable unit and is used for respectively acquiring the transmitting end electrical parameters and the receiving end electrical parameters so as to control the transmitting end adjustable unit to adjust the output transmitting end electrical parameters and control the receiving end electrical parameters output by thereceiving end adjustable unit to adjust. The transmitting end and the receiving end are respectively provided with an adjustable unit, and double-side adjustment is achieved by adjusting the transmitting end and the receiving end. The timeliness of adjustment can be reduced; the influence of the adjusting range is broken through; and the two sides are jointly adjusted, so that the adjusting precision is higher.

Owner:BEIJING INVISPOWER TECH CO LTD

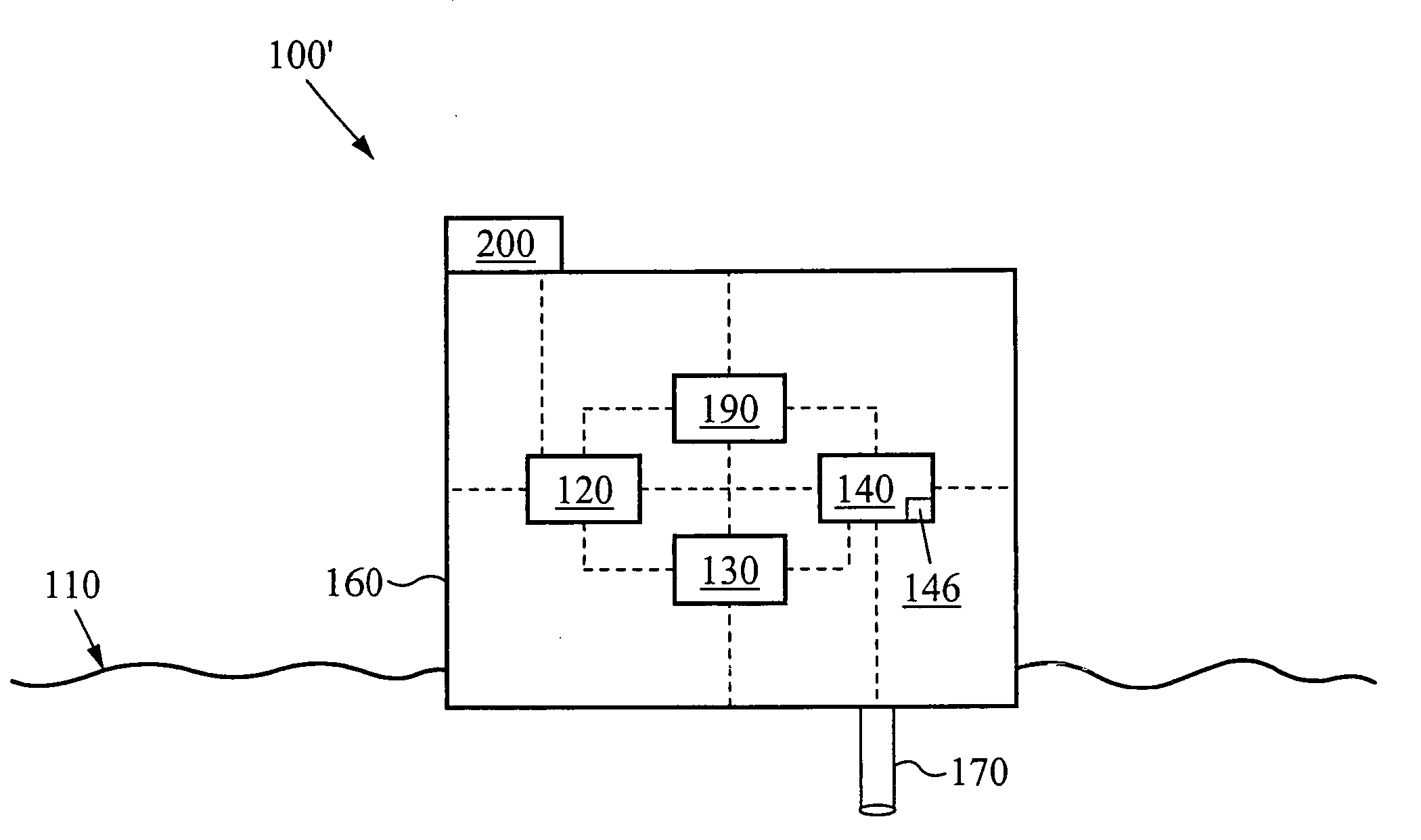

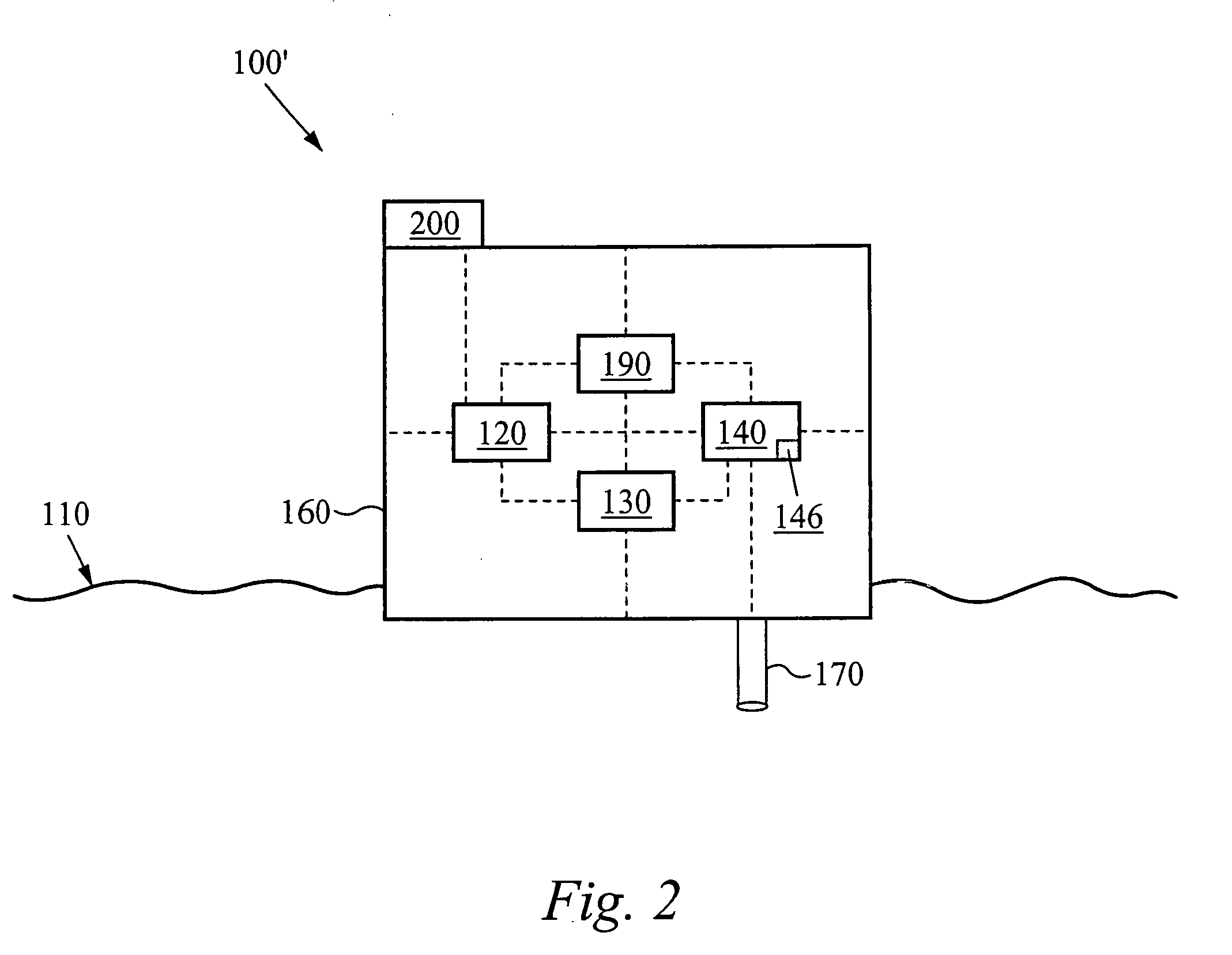

In-situ water analysis method and system

InactiveUS20070160498A1Improve securityImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesWaterborne vesselsProcess chemistryAnalysis method

An automatic system for monitoring chemistry information for a body of water comprises a sensor for determining chemistry information, a microprocessor for processing chemistry information, and a housing coupled to at least one of the sensor and the microprocessor. Preferably the housing is floatable or mountable. The method of providing chemistry information of a body of water comprising the steps of obtaining a sample of the body of water and determining chemistry information.

Owner:PENTAIR WATER POOL & SPA INC

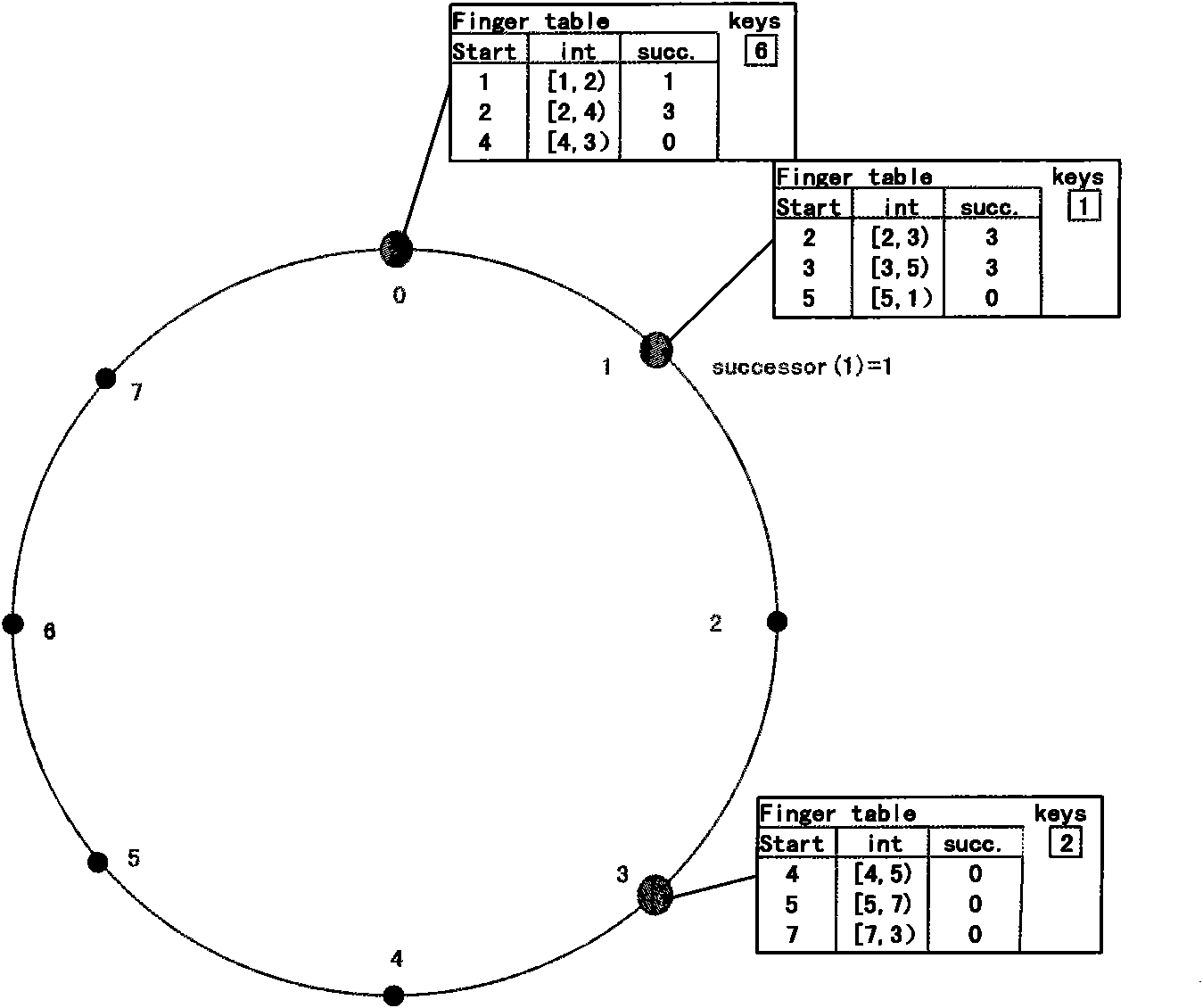

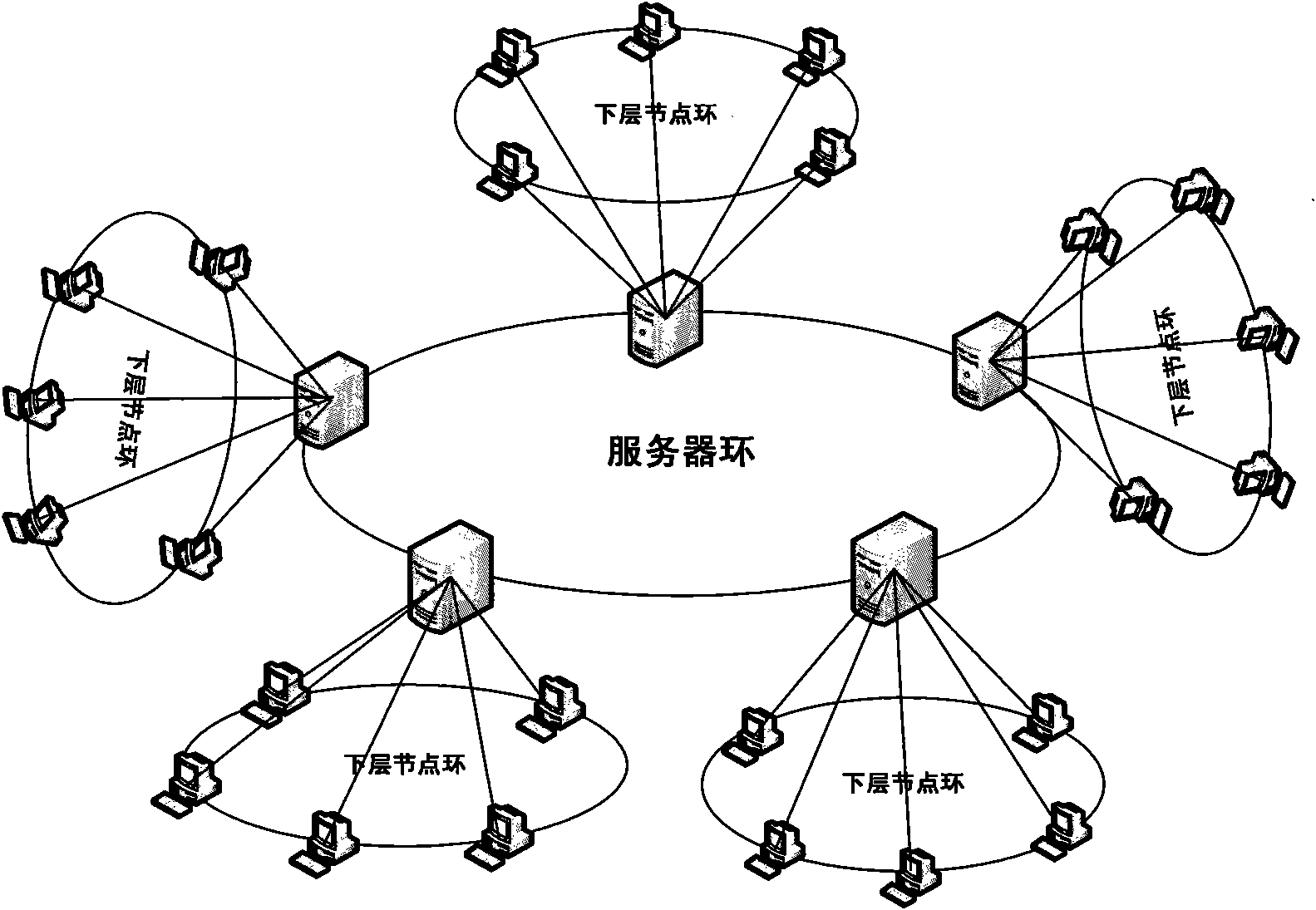

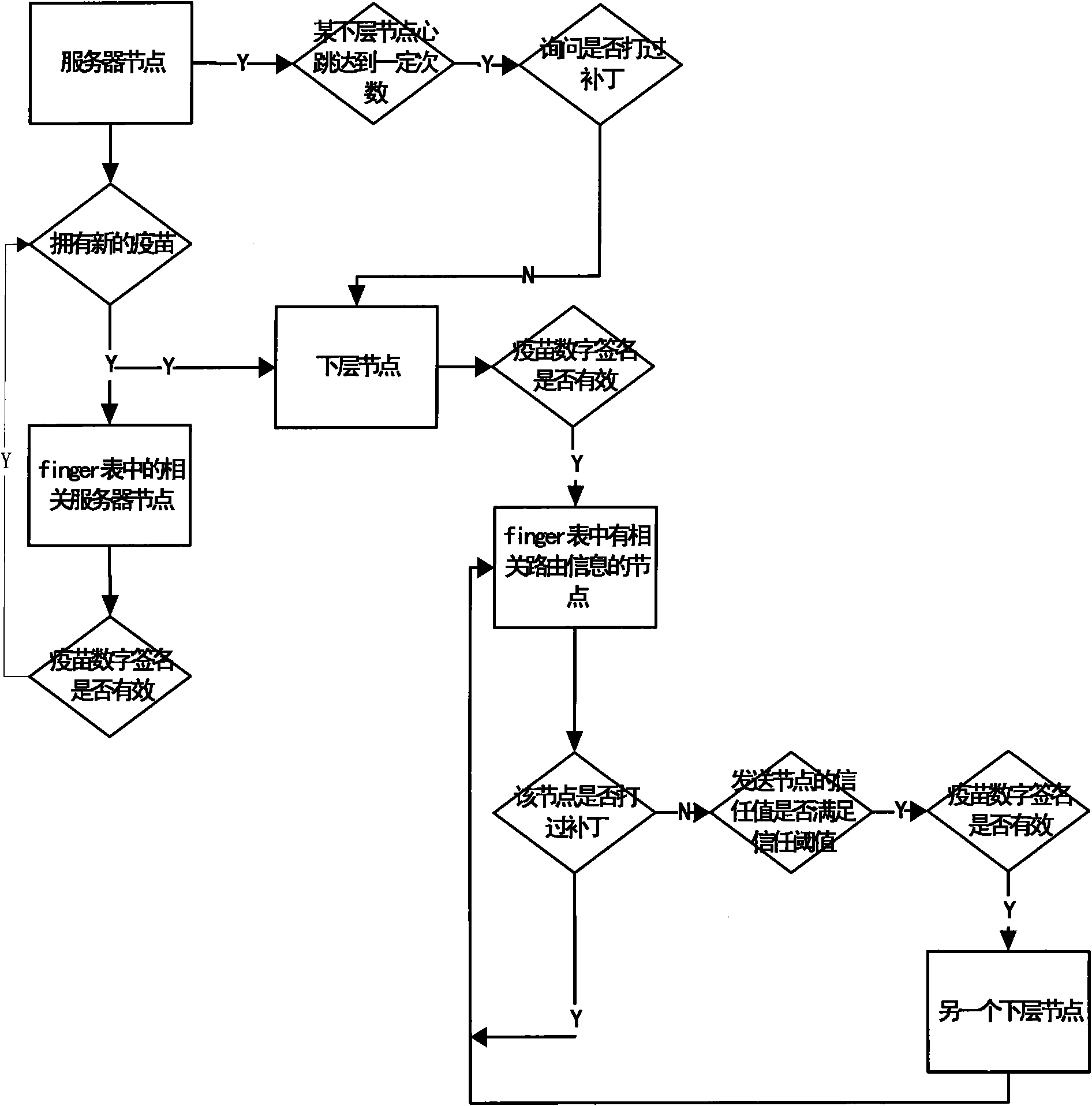

Vaccine distributing method based on double-layer Chord ring network

The invention discloses a vaccine distributing method based on a double-layer Chord ring network, belonging to the technical field of computer virus prevention and control. In the invention, the resource of non-server nodes in the network is fully utilized to increase the efficiency of vaccine distribution by constructing one compound double-layer Chord ring network, and the safety problem of vaccine transmission is solved by establishing a trust mechanism. Compared with the prior art, the invention efficiently reduces the load of a server.

Owner:NANJING UNIV OF POSTS & TELECOMM

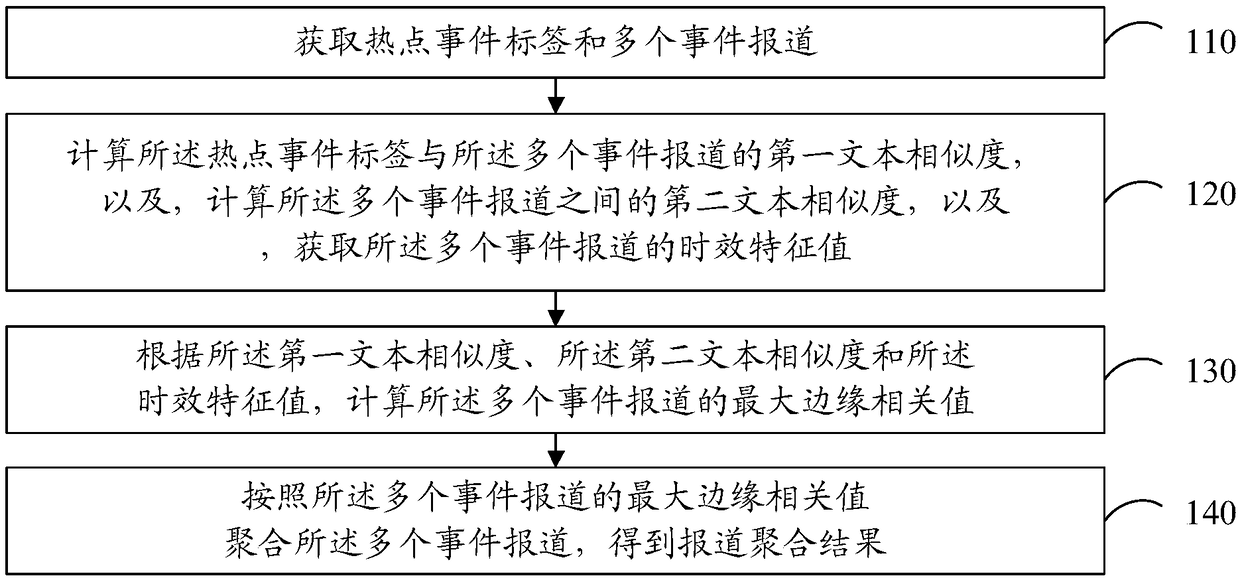

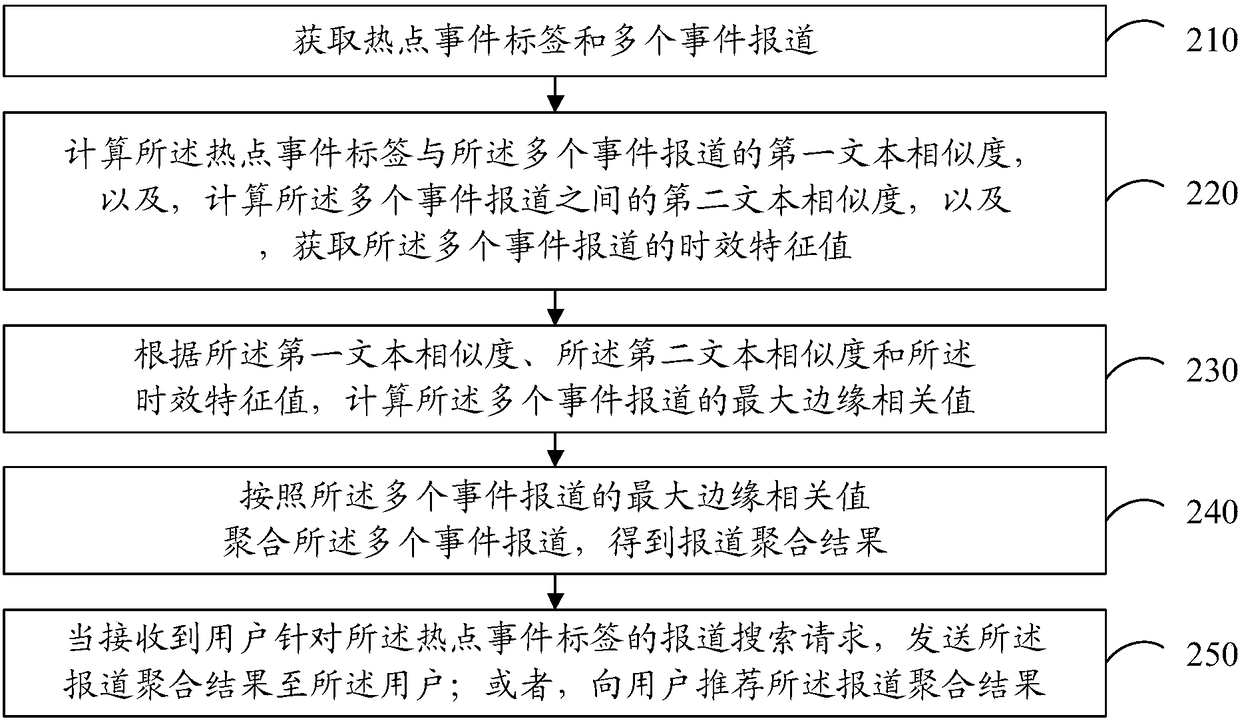

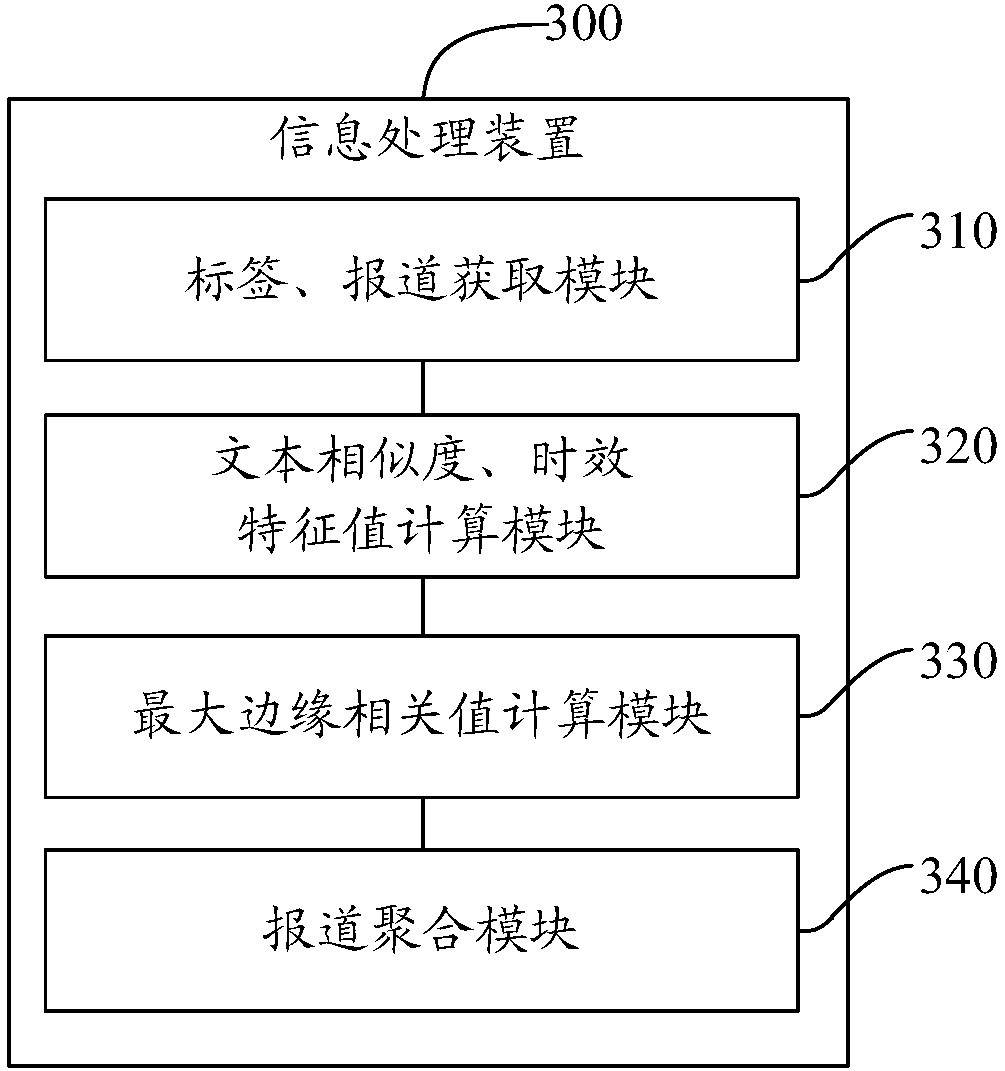

Information processing method and apparatus

ActiveCN108446296AReduce diversityDiversity saves user acquisition withSemantic analysisSpecial data processing applicationsInformation processingData mining

Embodiments of the invention provide an information processing method and apparatus. The method comprises the steps of obtaining a hotspot event tag and multiple event reports; calculating first textsimilarity between the hotspot event tag and the event reports, calculating second text similarity among the event reports, and obtaining timeliness eigenvalues of the event reports; according to thefirst text similarity, the second text similarity and the timeliness eigenvalues, calculating maximal marginal relevance values of the event reports; and according to the maximal marginal relevance values of the event reports, aggregating the event reports to obtain a report aggregation result. According to the information processing method and apparatus, the time and energy of a user in obtainingthe event reports with diversity and timeliness are saved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

Carbon steel containing vanadium and titanium and manufacture method thereof

The invention provides carbon steel containing vanadium and titanium and a manufacture method thereof. The manufacture method comprises the following steps of: primarily melting molten steel; when C content of the molten steel is 0.05-0.10 percent, P content is not more than 0.015 percent and S content is not more than 0.020 percent, tapping to a steel ladle; during the tapping, regulating the Si content of the molten steel to be 0.17-0.37 percent and the Mn content to be 0.70-1.00 percent, and regulating the oxygen content of the molten steel to be below 0.0020 percent; controlling the Als content of the molten steel to be 0.015-0.025 percent, wherein the Als represents acid dissolved aluminum; regulating the oxygen content of the molten steel to be below 0.0010 percent in a steel ladle refining furnace; regulating the Ti content of the molten steel to be 0.005-0.010 percent and the V content to be 0.02-0.04 percent; and regulating the C content of the molten steel to be 0.17-0.23 percent so that the carbon steel is obtained, wherein the carbon steel comprises the following components in percent by weight of 0.17-0.23 percent of C, 0.17-0.37 percent of Si, 0.70-1.00 percent of Mn, 0.005-0.010 percent of Ti, 0.005-0.010 percent of Als, 0.02-0.04 percent of V and the balance of Fe and unavoidable impurities.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

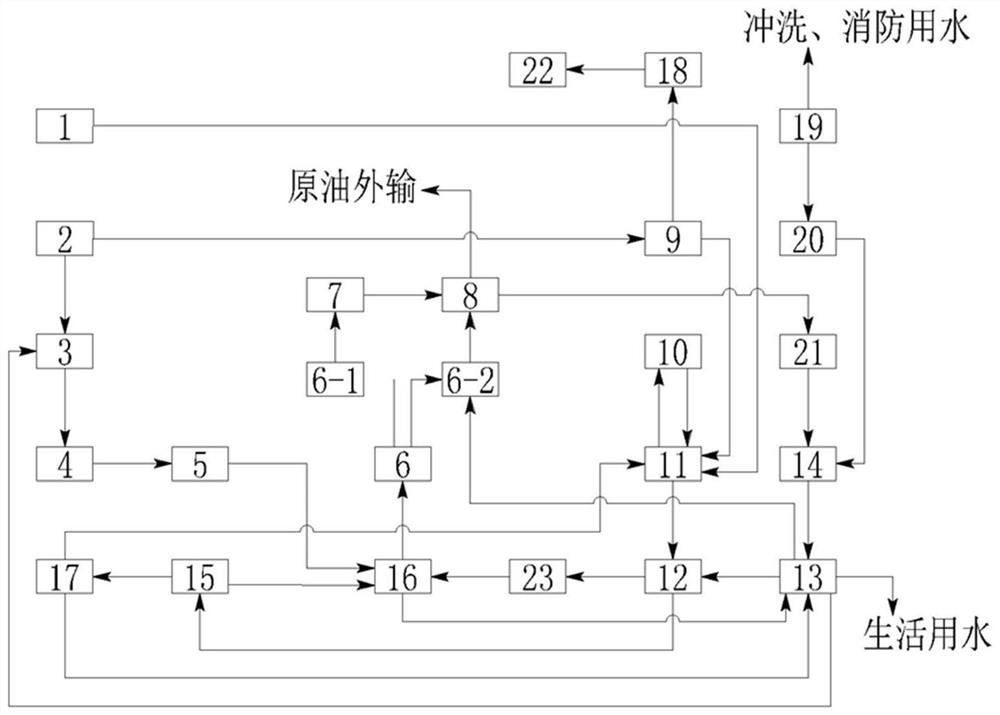

System for offshore oilfield steam thermal exploitation by utilizing wind power and photovoltaic power

PendingCN112796722AReduce timelinessReduce randomnessElectrolysis componentsPV power plantsThermodynamicsOil field

The invention provides a system for offshore oilfield steam thermal exploitation by utilizing wind power and photovoltaic power. The system comprises a pure water preparation and storage subsystem, a hydrogen production subsystem, a novel energy storage subsystem, a crude oil collection and conveying subsystem and a wind-solar complementary power generation subsystem. According to the system for offshore oilfield steam thermal exploitation by utilizing wind power and photovoltaic power, the advantage that most of regions where an offshore oilfield is located are regions rich in wind energy and solar energy is utilized, and renewable energy sources (wind energy and solar energy) are introduced into a thickened oil or super-thickened oil exploitation system, so that the renewable energy sources are fully utilized. The solar energy and the wind energy are complementary, so that the timeliness and randomness of the renewable energy sources can be greatly reduced. In order to avoid the problem that the oil extraction effect is influenced due to the fact that the system cannot continuously generate steam due to simultaneous insufficiency of wind and light resources, an energy storage mode of saturated water and hydrogen of the novel energy storage subsystem is adopted, and the system can be kept running under the accidental condition without solar energy or wind energy.

Owner:HENAN HENGJU NEW ENERGY EQUIP CO LTD

Wireless charging system

PendingCN110932374AReduce timelinessHigh adjustment accuracyBatteries circuit arrangementsElectric powerTelecommunicationsControl theory

The invention discloses a wireless charging system which is provided with a transmitting end and a receiving end. The transmitting end comprises a transmitting end adjustable unit, and the receiving end comprises a receiving end adjustable unit. The receiving end adjustable unit responds to a receiving end adjusting parameter and adjusts an output electrical parameter, and the transmitting terminal adjustable unit responds to a transmitting terminal adjusting parameter and adjusts an output electrical parameter. The transmitting end adjustment parameter is related to a first interaction parameter generated by the receiving end. The transmitting end and the receiving end are respectively provided with the adjustable units, so that the bilateral adjustment is realized. The first interactionparameter associates the adjustment of the two sides, so that the two sides can work cooperatively. Moreover, based on the two-side adjustment, the two sides are adjusted respectively rather than theadjustment work at one side, so that the adjustment timeliness of the transmitting end can be reduced. By the common adjustment, the adjustment precision is higher.

Owner:BEIJING INVISPOWER TECH CO LTD

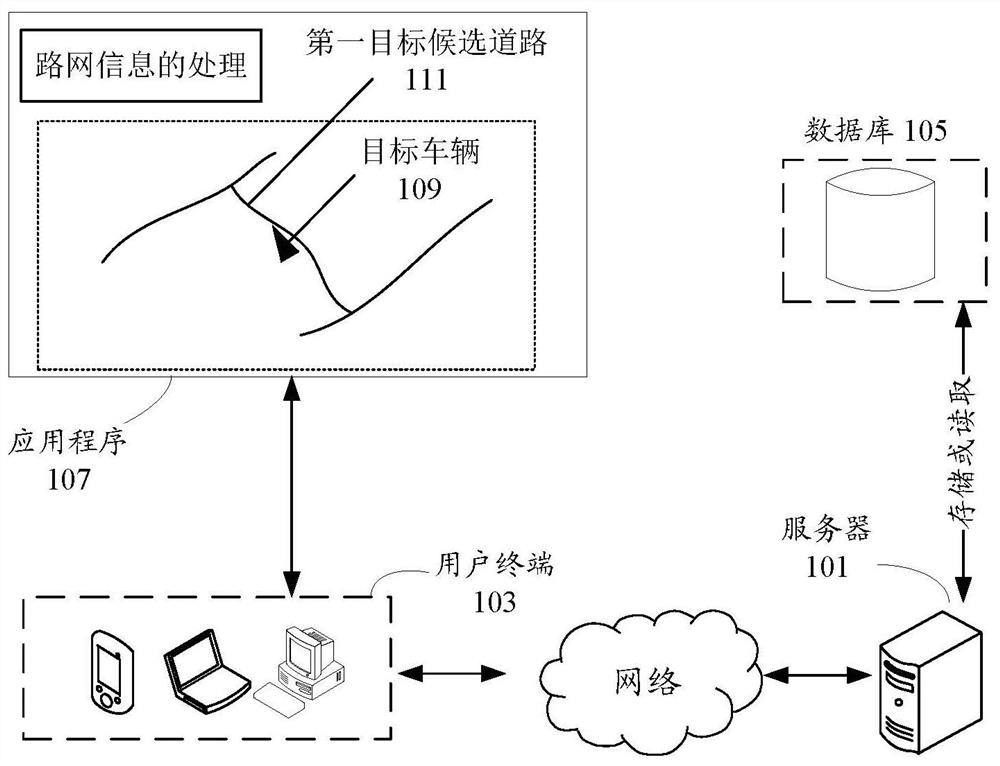

Road network information processing method and device, storage medium and electronic equipment

ActiveCN112380314AImprove processing efficiencyReduce processing costsGeographical information databasesSpecial data processing applicationsInformation processingSimulation

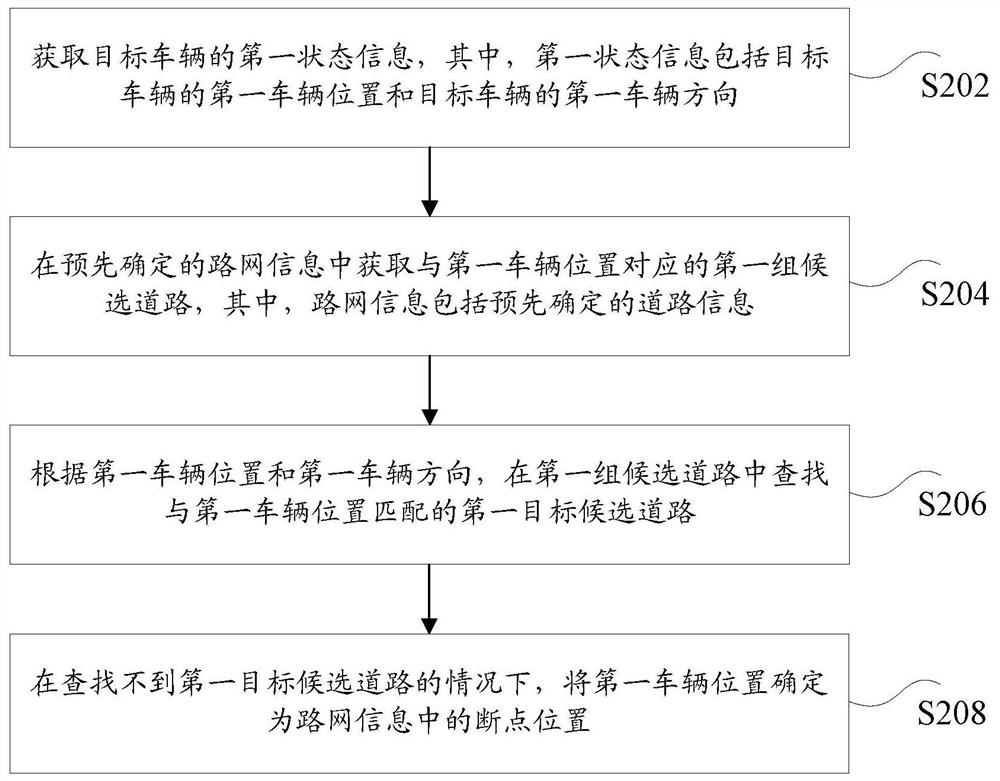

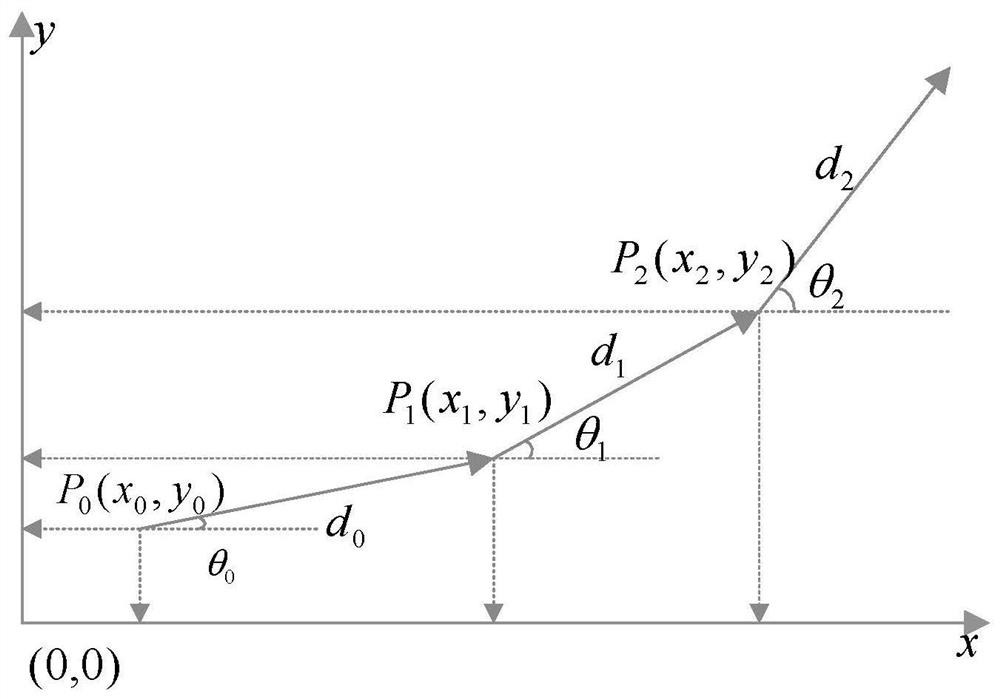

The invention discloses a road network information processing method and device, a storage medium and electronic equipment. The method comprises the following steps: acquiring first state informationof a target vehicle, acquiring a first group of candidate roads corresponding to a first vehicle position in predetermined road network information, and searching a first target candidate road matchedwith the first vehicle position in the first group of candidate roads according to the first vehicle position and a first vehicle direction, and under the condition that the first target candidate road cannot be found, determining the position of the first vehicle as a breakpoint position in the road network information. The technical problem that the road network information processing efficiency is low due to the fact that the road network information processing process is complex in the prior art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Freight company carrying method

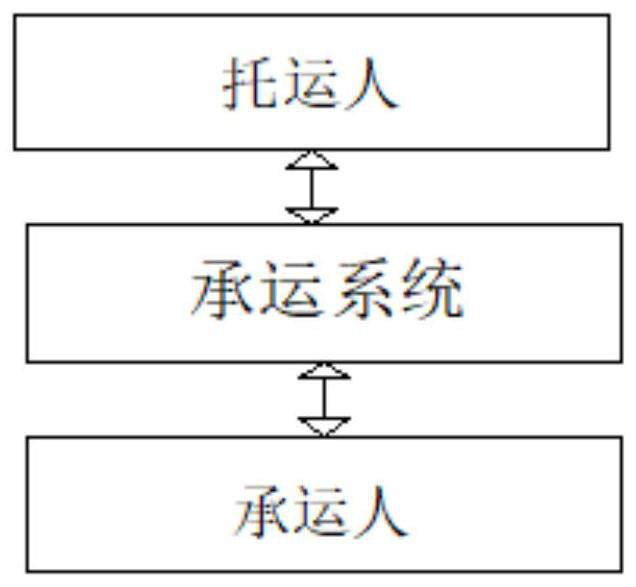

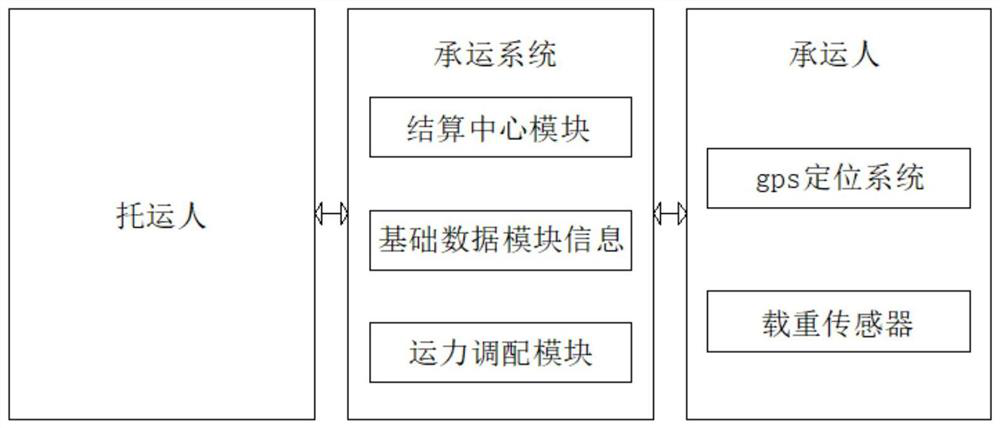

PendingCN112418750AImprove efficiencyWork lessSatellite radio beaconingResourcesLogistics managementInformation networks

The invention provides a freight company carrying method, which comprises a consignor, a carrying system and a carrier, and is characterized in that the carrying system is an intermediate integrator,is a resource integrator, screens transportation services of socialized carriers and outsourcing carriers, and issues the transportation services to the carrier, and the carrier carries out transportation operation on the transportation services of the consignor. Compared with traditional services, the timeliness is low, the cost is high, the efficiency and the working level of the whole logisticsindustry are greatly improved through the carrying system, and due to the fact that the carrying system is established on the Internet, an information network is applied, a large number of information sources are mastered, and effective integration of virtual and physical networks is achieved by mastering existing physical resources. The logistics transportation efficiency is improved, from the long-term perspective, resource intensive integration and industry standard development of the freight market are effectively promoted through innovation of the Internet means and the organization modeby means of the carrying system, and the logistics transportation system has important significance in promoting transformation upgrading and quality and efficiency improvement of the logistics freight industry.

Owner:广东货司通科技有限公司

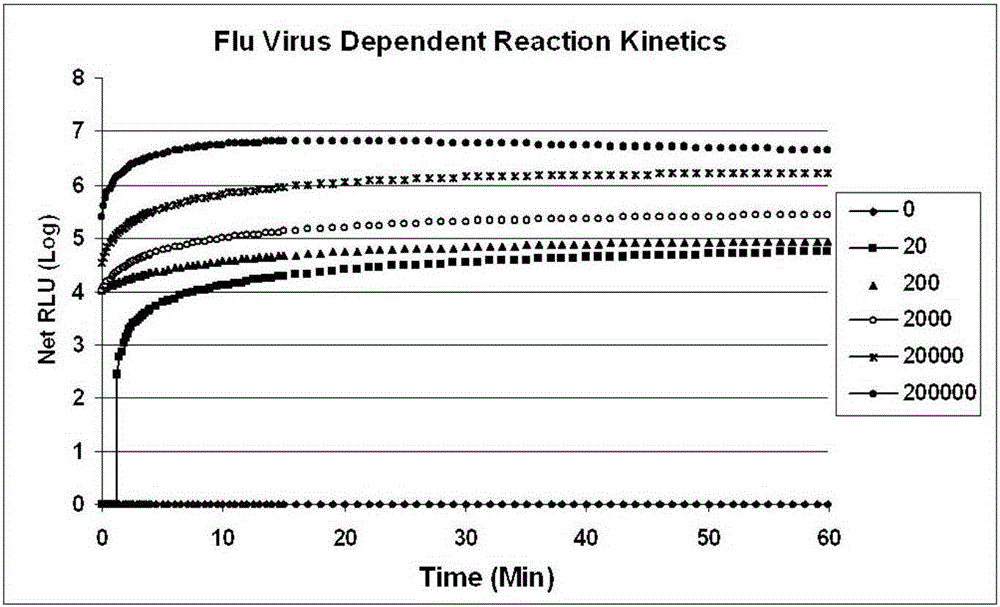

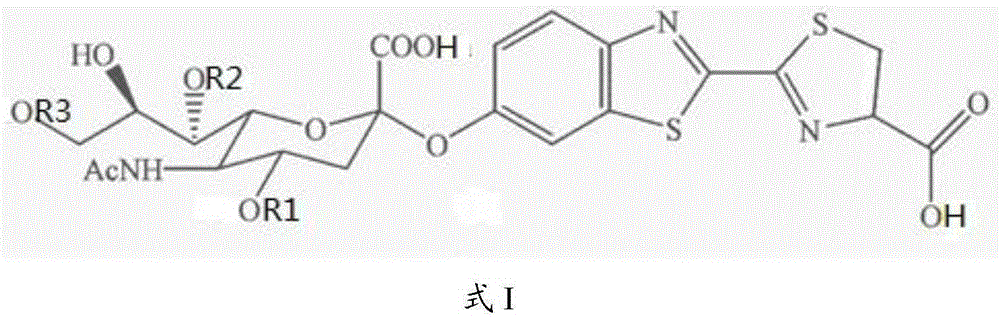

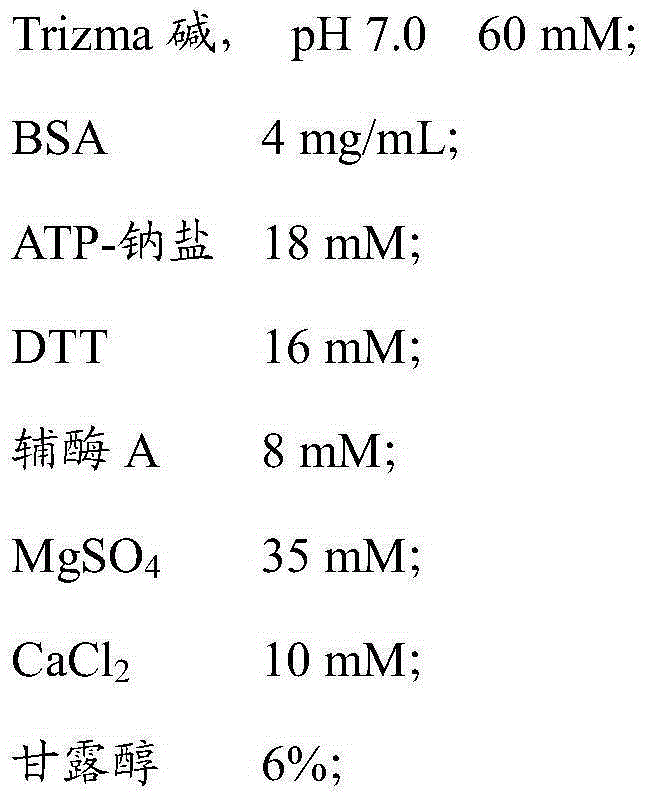

Influenza virus real-time detection kit and method

InactiveCN105274252AReduced autolysisGuaranteed timelinessMicrobiological testing/measurementFirefly luciferinN-Acetylneuraminic acid

The invention discloses an influenza virus real-time detection kit and a method. The real-time detection kit comprises a detection composition, the pH value of the detection composition is 7.0-7.2, and the detection composition comprises N-acetylneuraminic acid-firefly luciferin conjugate or a salt thereof and firefly luciferase. The real-time detection method comprises combining influenza virus and the detection composition in the environment with the pH value of 7.0-7.2, and then detecting the firefly luciferin signal. According to the detection composition contained by the real-time detection kit, by limiting the ingredients in the detection composition and further limiting the content of the ingredients, detection on ceramidease of influenza virus does not need dividing into two steps, and a one-step reaction can be performed only by directly mixing the detection composition and influenza virus. When relatively high detection sensitivity is guaranteed, operation steps are simplified and real-time detection is realized.

Owner:CELLEX BIOLOGICAL TECH SUZHOU CO LTD

Film-coated metal plate

ActiveCN111231451ASimple production processEasy constructionRoof covering using slabs/sheetsSynthetic resin layered productsAdhesive cementPolymer science

The invention relates to a film-coated metal plate which comprises a metal plate body, a macromolecule adhesive film layer on the metal plate body and a TPO layer on the macromolecule adhesive film layer. The TPO layer comprises the following components: 20-100 parts of an ethylene-olefin copolymer; 10 to 40 parts of polypropylene; 5-30 parts of titanium dioxide; 0-40 parts of a filler; 0.1 to 2 parts of an antioxidant; and 0.1 to 2 parts of an anti-ultraviolet agent. The TPO layer and the metal plate are connected into a whole through the macromolecule adhesive film layer, the production process is simple, one-time forming is achieved, construction is convenient, operation is flexible, the construction period is effectively shortened, and the macromolecule adhesive film layer effectivelyavoids the environmental protection problem related to a traditional adhesive. A metal roofing board adopting the TPO layer can be designed with a durable life, and the conventional durable life is guaranteed for 10 years. The TPO layers of the adjacent steel plates are connected in a welded mode, and the problem that rivets are exposed outside and are prone to corrosion, so that the connecting strength is reduced is solved.

Owner:苏州凯伦高分子新材料科技有限公司

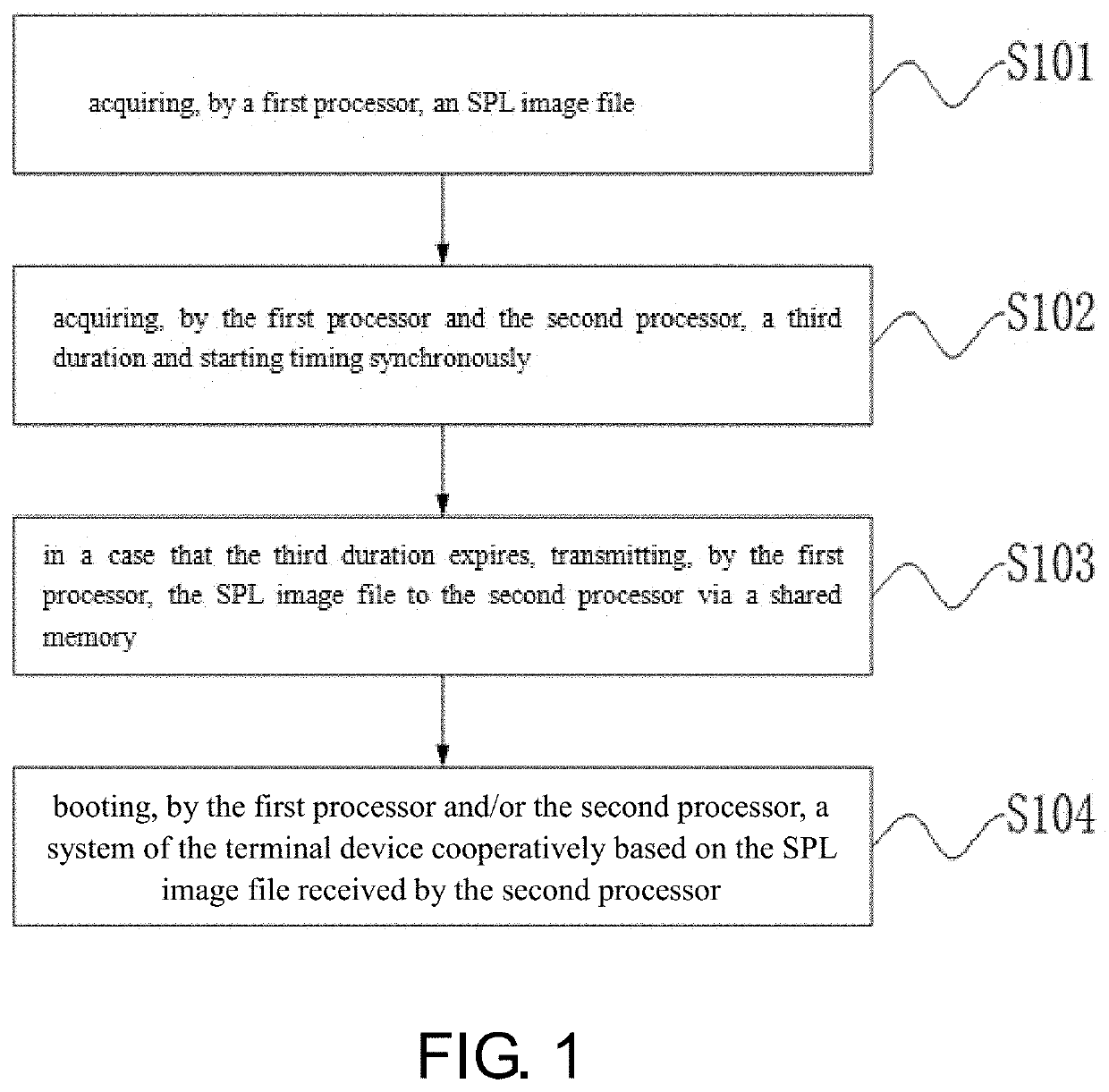

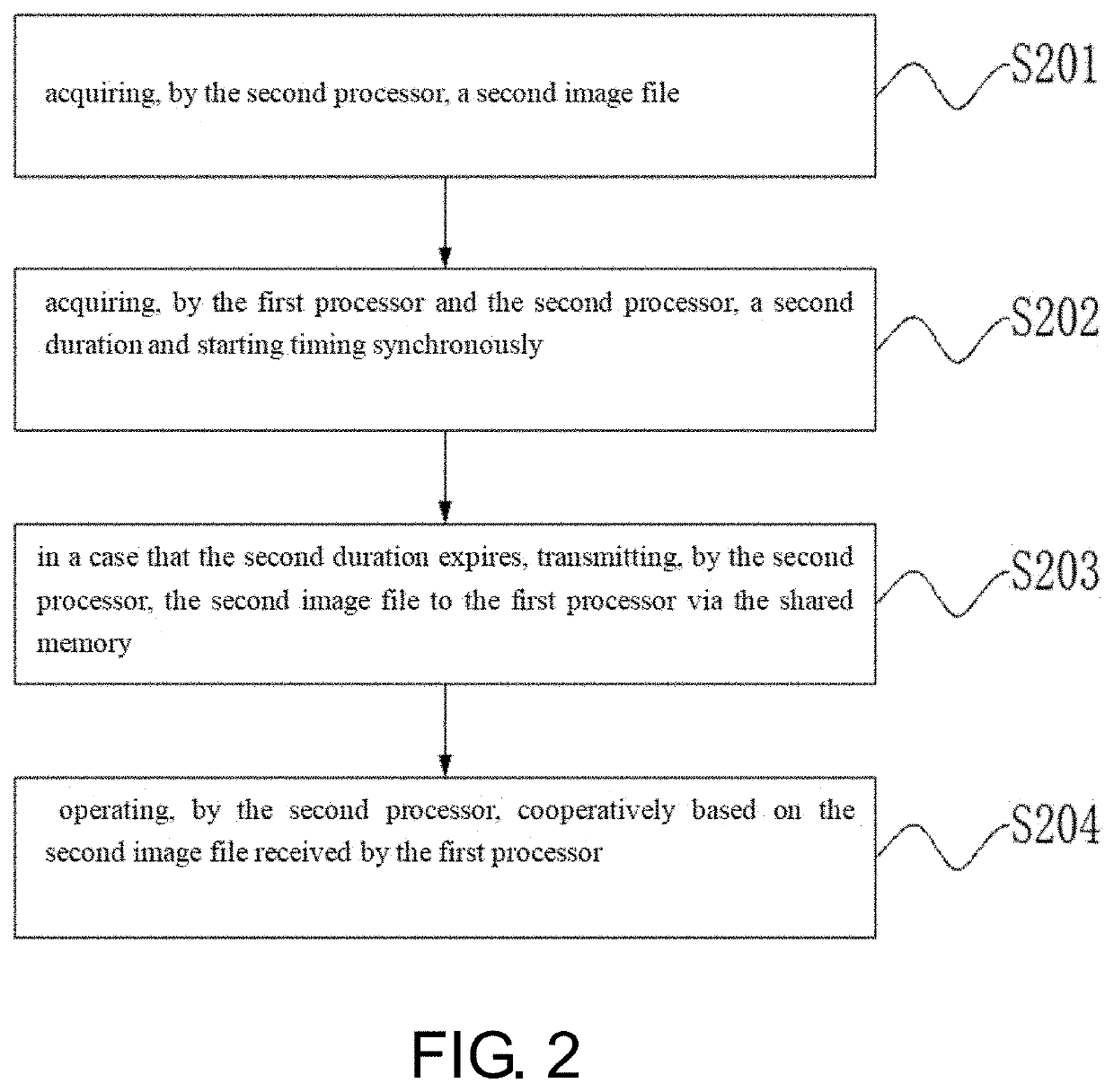

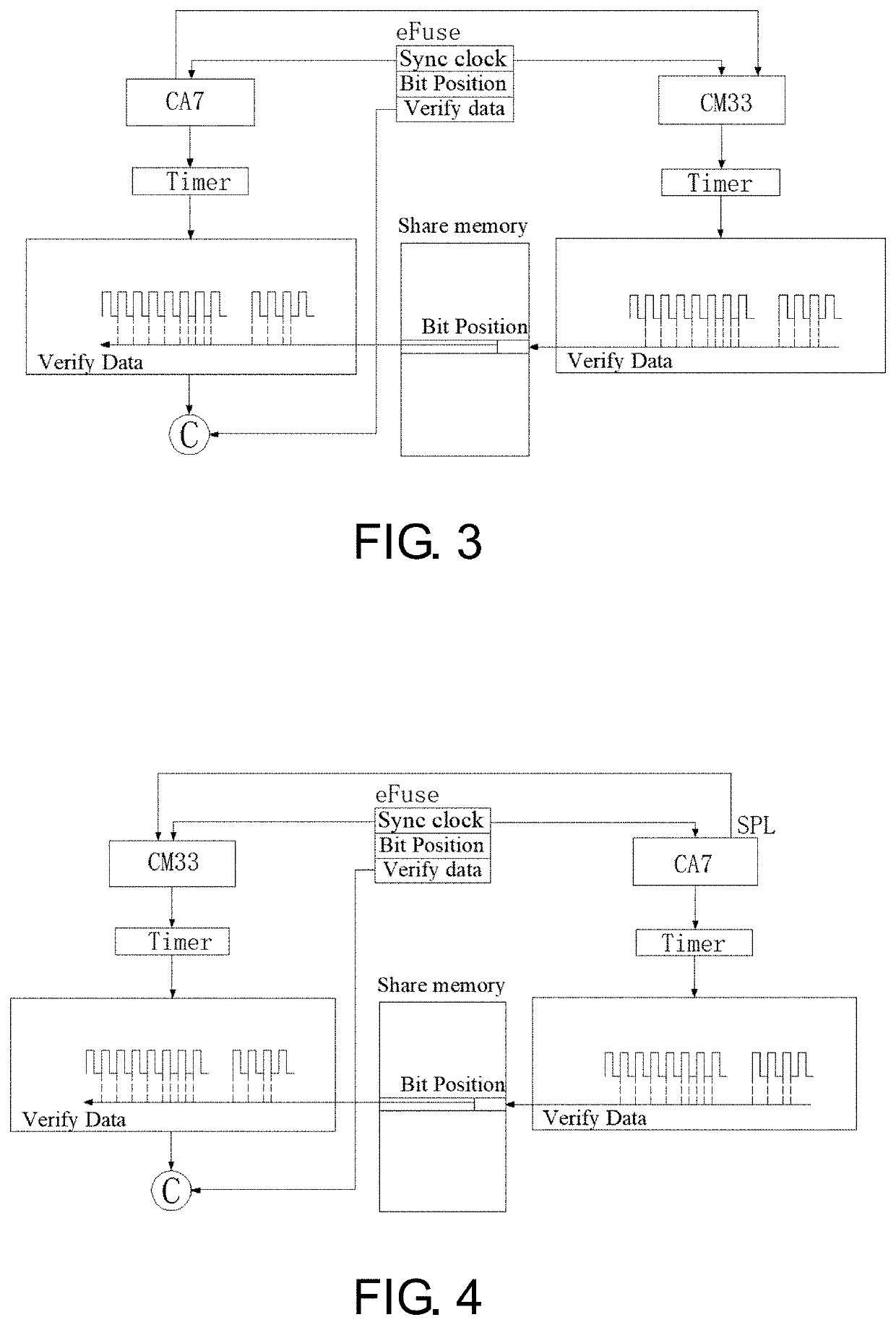

Secure boot method for terminal device, terminal device and medium

ActiveUS20210334383A1Environment safetyImprove securityInternal/peripheral component protectionBootstrappingStart timeTerminal equipment

The invention discloses a secure boot method for a terminal device, a terminal device and a medium, relates to the technical field of secure boot, and is used for solving a problem of low system boot security caused by lack of protection for system boot in the related art. The terminal device includes a first processor, a second processor and a shared memory. The method includes: acquiring, by the first processor, an SPL image file; acquiring, by the first processor and the second processor, a third duration and starting timing synchronously; in a case that the third duration expires, transmitting, by the first processor, the SPL image file to the second processor via the shared memory; and booting, by the first processor and / or the second processor, a system of the terminal device cooperatively based on the SPL image file received by the second processor.

Owner:HANGZHOU VANGO TECH

Vanadium-titanium containing carbon steel and manufacturing method thereof

The invention provides vanadium-titanium containing carbon steel and a manufacturing method thereof. The manufacturing method comprises the following steps of: primarily smelting to obtain molten steel; discharging steel to a steel ladle when the content of C in the molten steel is 0.05-0.10 percent, the content of P is not more than 0.015 percent, and the content of S is not more than 0.020 percent; in the process of discharging the steel, regulating the content of Si of the molten steel to be 0.17-0.37 percent, the content of Mn to be 0.35-0.65 percent and the content of oxygen of the molten steel to be below 0.0020 weight percent; controlling the content of Als of the molten steel to be 0.015-0.025 percent, wherein Als represents acid soluble aluminum; regulating the content of oxygen of the molten steel in a steel ladle refining furnace to be below 0.0010 percent; regulating the content of Ti of the molten steel to be 0.005-0.010 percent and the content of V to be 0.02-0.04 percent; and regulating the content of C of the molten steel to be 0.17-0.23 percent so as to obtain the carbon steel, wherein the carbon steel contains the following components in percentage by weight: 0.17-0.23 percent of C, 0.17-0.37 percent of Si, 0.35-0.65 percent of Mn, 0.005-0.010 percent of Ti, 0.005-0.010 percent of Als, 0.02-0.04 percent of V and the balance of Fe and unavoidable impurities.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

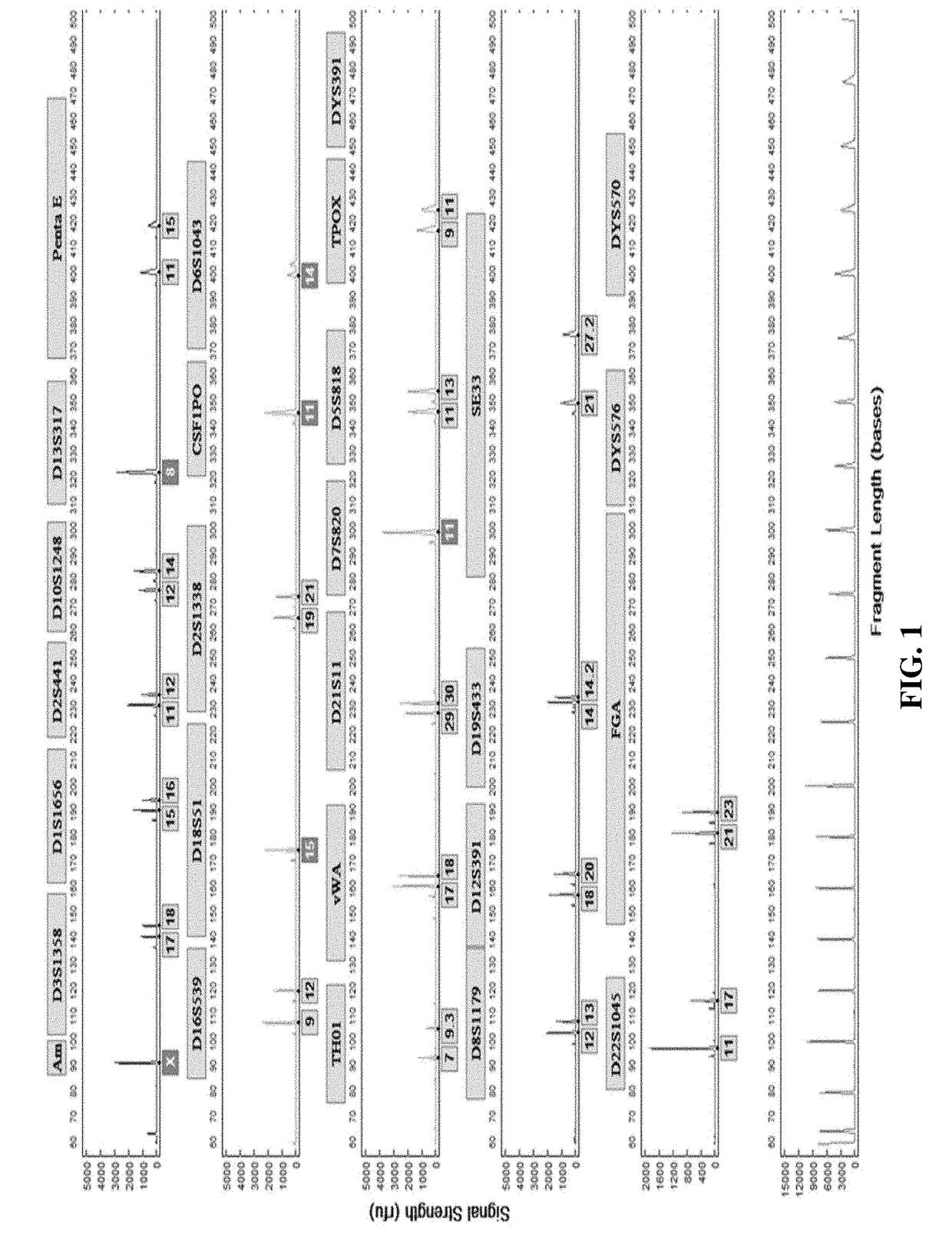

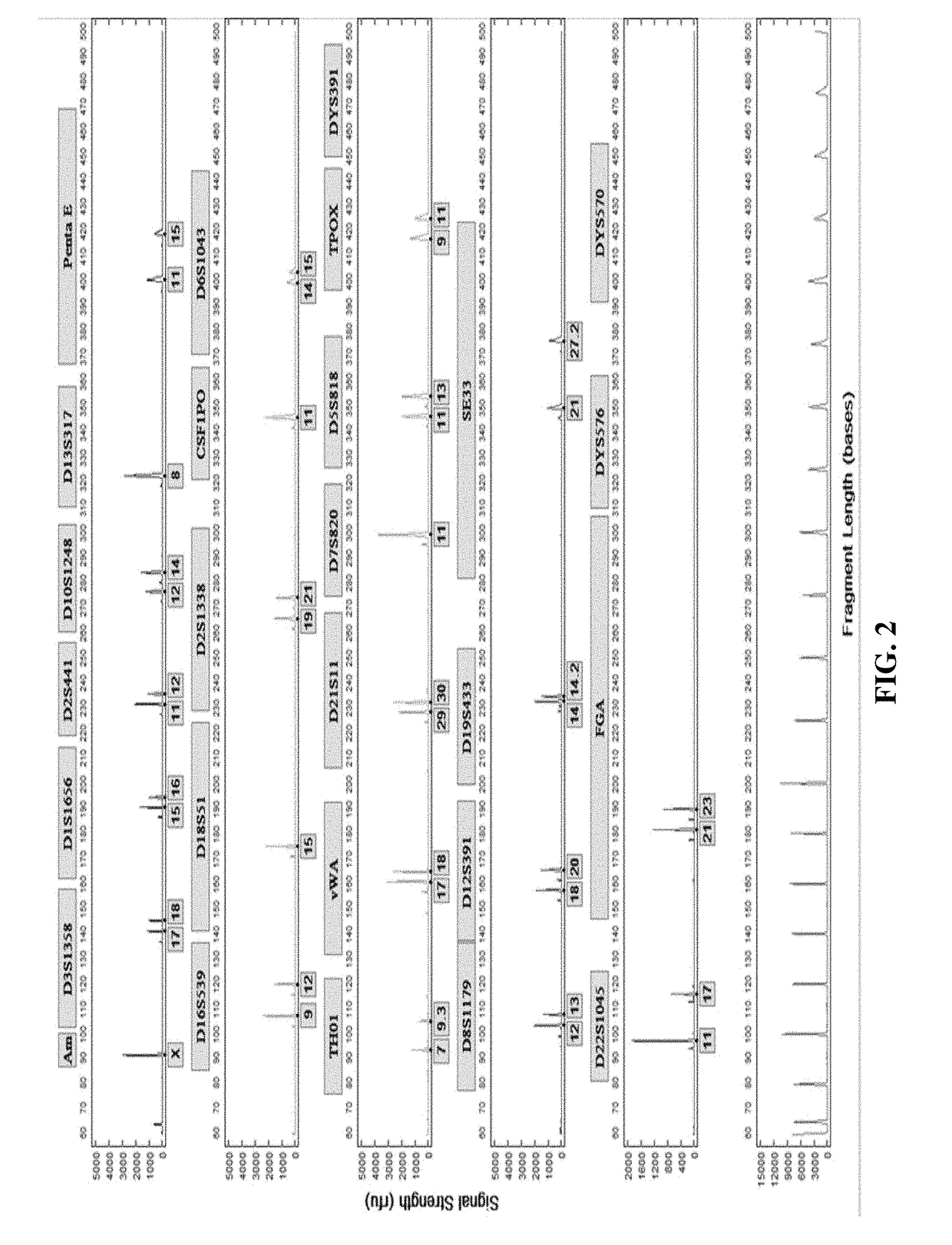

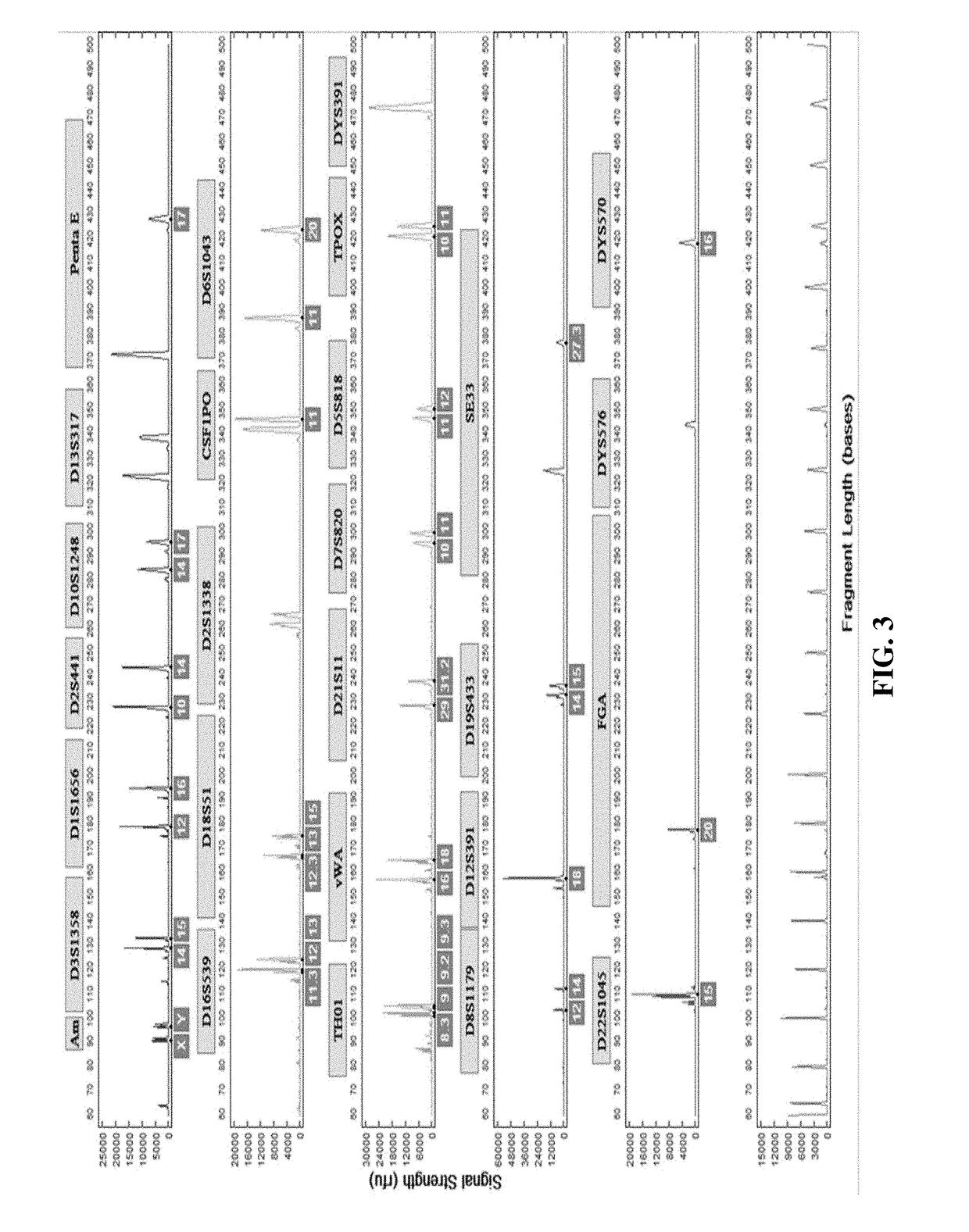

Pattern Recognition System

PendingUS20190019290A1Easy to analyzeReduce re-runsImage enhancementImage analysisSelf adaptivePattern recognition system

Owner:ANDE CORP

Alloy steel and manufacture method thereof

The invention provides alloy steel and a manufacture method thereof. The manufacture method comprises the steps of: initially melting molten steel; when C content is 0.03-0.06 percent, P content is not more than 0.015 percent and S content is not more than 0.020 percent, tapping to a steel ladle; during the tapping, regulating the Si content to be 0.17-0.37 percent, the Mn content to be 0.40-0.70 percent, the Cr content to be 0.80-1.10 percent and the Mo content to be 0.40-0.55 percent, and regulating the oxygen content of molten steel to be below 0.0020 percent; controlling the Als content to be 0.015-0.025 percent in a steel ladle refining furnace, wherein Als expresses acid-soluble aluminum; regulating the oxygen content of the molten steel to be below 0.0010 percent in the steel ladle refining furnace; regulating the Ti content of the molten steel to be 0.005-0.010 percent and the V content to be 0.02-0.04 percent in the refining process, the C content of the molten steel to be 0.12-0.18 percent after the refining is finished so as to obtain the alloy steel, wherein the alloy steel comprises the following components in percent by weight of 0.12-0.18 percent of C, 0.17-0.37 percent of Si, 0.40-0.70 percent of Mn, 0.80-1.10 percent of Cr, 0.40-0.55 percent of Mo, 0.005-0.010 percent of Ti, 0.005-0.010 percent of Als, 0.02-0.04 percent of V and the balance of Fe and inevitable impurities.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Alloy steel and manufacturing method thereof

InactiveCN102031452BAvoid problemsPrevents degradation of impact resistanceOxygen contentMolten steel

The invention provides an alloy steel and a manufacturing method thereof. The manufacturing method comprises the steps of: primarily smelting steel into molten steel; when the C content of the molten steel is 0.03-0.06 percent, the P content is not more than 0.015 percent and the S content is not more than 0.020 percent, tapping a steel ladle; during tapping, regulating the Si content of the molten steel to be 0.17-0.37 percent, Mn content to be 0.40-0.70 percent, Cr content to be 0.80-1.10 percent and Mo content to be 0.40-0.55 percent, and regulating the oxygen content of the molten steel to be below 0.0020 percent; controlling the Als content of the molten steel to be 0.02-0.0 percent, wherein Als represents acid-soluble aluminium; ensuring that the oxygen content is below 0.0010 percent when the molten steel is refined and the C content of the molten steel is 0.12-0.18 percent after the refining is ended in a steel ladle refining furnace; and carrying out circulating vacuum degassing treatment on the molten steel, and regulating the Ti content of the molten steel to be 0.006-0.010 percent to obtain the alloy steel. The alloy steel comprises the following components in percent by weight: 0.12-0.18 percent of C, 0.17-0.37 percent of Si, 0.40-0.70 percent of Mn, 0.80-1.10 percent of Cr, 0.40-0.55 percent of Mo, 0.006-0.010 percent of Ti, 0.008-0.015 percent of Als and the balance of Fe and unavoidable impurities.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com