Cold-rolled enamelled steel and production method thereof

A production method and technology for enamel steel, applied in the field of cold-rolled enamel steel, can solve the problem of high smelting cost, and achieve the effects of excellent surface quality, good economic benefits, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

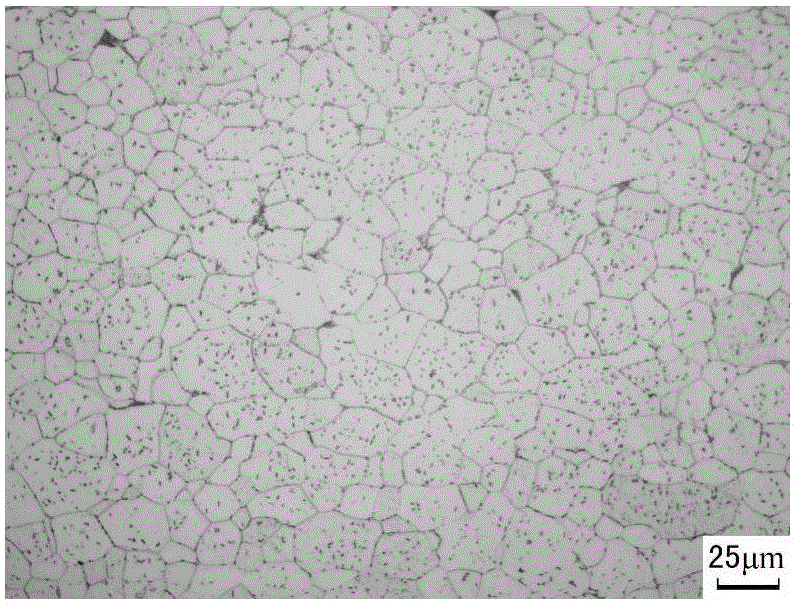

[0034] Select the chilled steel coil with the chemical composition of Example 1 in Table 1 below for continuous annealing production, the thickness is 1.8 mm, the hot rolling coiling temperature is 745 ° C, the cold rolling reduction rate is 75%, and the annealing temperature is shown in Table 2 shown. The steel running speed in the annealing furnace is 93m / min, and the flat elongation rate is 1.5%. The transverse mechanical properties of the finished product are shown in Table 3, and the microstructure is as follows: figure 1 shown. Enameling trial production was carried out, and the coating has good adhesion and no scaling phenomenon. The national standard GB / T29515-2013 is used for hydrogen permeation test, and its TH value is 54.45min / mm 2 .

Embodiment 2

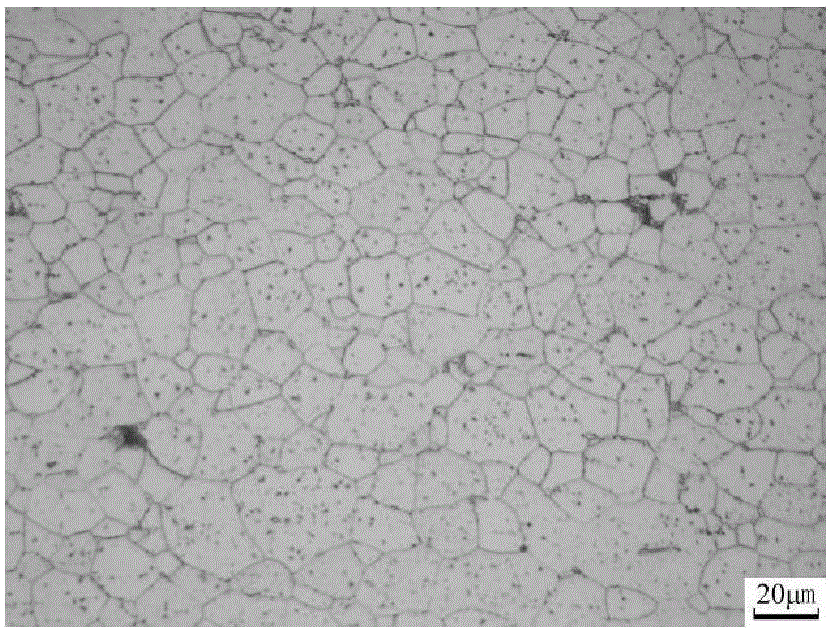

[0036] Select the chilled steel coil with the chemical composition of Example 2 in Table 1 below for continuous annealing production, the thickness is 1.8mm, the hot rolling coiling temperature is 740°C, and the cold rolling reduction rate is 75%. The annealing temperature is as shown in the table 2. The steel running speed in the annealing furnace is 89m / min, and the flat elongation rate is 1.5%. The transverse mechanical properties of the finished product are shown in Table 3, and the microstructure is as follows: figure 2 shown. Enameling trial production was carried out, and the coating has good adhesion and no scaling phenomenon. The national standard GB / T29515-2013 was used for the hydrogen permeation test, and the TH value was 59.16min / mm2.

Embodiment 3

[0038] Select the chilled steel coil with the chemical composition of Example 3 in Table 1 below for continuous annealing production, the thickness is 0.7 mm, the hot rolling coiling temperature is 737 ° C, the cold rolling reduction rate is 75%, and the annealing temperature is shown in Table 2 shown. The steel running speed in the annealing furnace is 163m / min, and the flat elongation rate is 0.9%. The transverse mechanical properties of the finished product are shown in Table 3. Enameling trial production is carried out, and the coating has good adhesion and no scales.

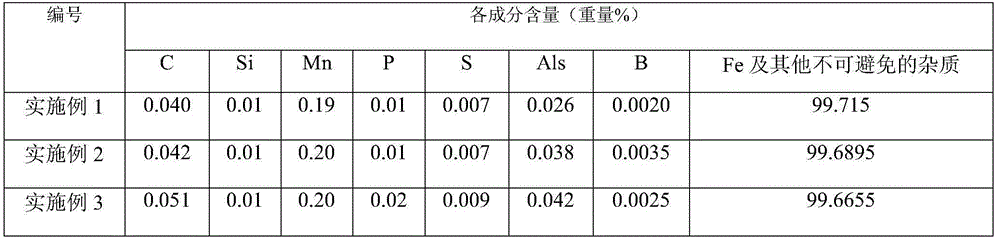

[0039] Chemical composition of chilled steel in Table 1 embodiment 1~3

[0040]

[0041] The annealing temperature of steel in table 2 embodiment 1~3

[0042] serial number

Soaking section (℃)

End point of slow cooling (℃)

Rapid cooling end point (℃)

Over-aging period (℃)

Example 1

833

688

337

371

Example 2

828

682

375

379

Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com