Production method of glassed steel

A production method and enamelled steel technology, applied in the field of cold-rolled strip production, can solve the problems of high production costs, achieve good market potential, and achieve the effects of good cost reduction and efficiency enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

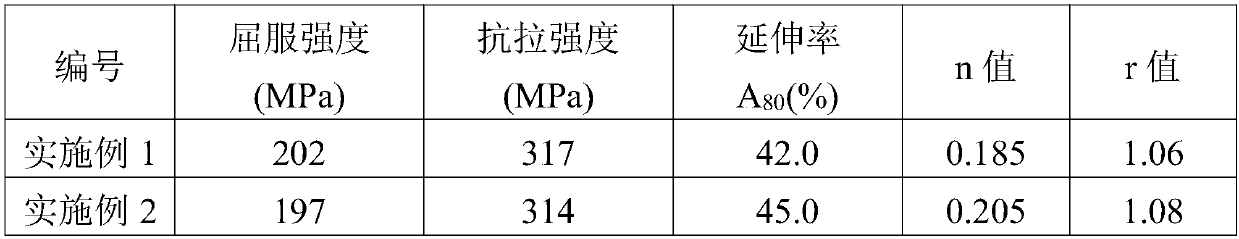

Embodiment 1

[0032] Example 1 Using the method of the present invention to produce enamel steel plate

[0033] It is produced with molten steel composed of chemical composition in weight percentage as shown below:

[0034] C

Si

Mn

P

S

Als

Fe and other inevitable impurities

0.049

0.01

0.23

0.006

0.011

0.055

99.639

[0035] 1. Casting the above molten steel into a slab;

[0036] 2. Hot rolling process: heating to 1236°C for rough rolling, final rolling temperature of 887°C, cooling to 715°C for coiling, hot rolling thickness of 6mm;

[0037] 3. Pickling process: pickling the hot-rolled coils above, the hydrochloric acid concentration of 1#, 2#, 3# acid tanks are 35~45 g / l, 50~80g / l, 100~130g / l, and the temperature is controlled separately At 80~85℃, 80~85℃, 80~85℃, the speed of pickling section is controlled at 100~240m / min, and then cold rolled into cold rolled thin strip steel, the cold rolling reduction rate is 70%;

[0038] 4. Bell-type annealing: the above cold-rolled thin strip steel is...

Embodiment 2

[0040] Example 2 Using the method of the present invention to produce enamel steel plate

[0041] It is produced with molten steel composed of chemical composition in weight percentage as shown below:

[0042] C

Si

Mn

P

S

Als

Fe and other inevitable impurities

0.042

0.01

0.25

0.01

0.007

0.036

99.645

[0043] 1. Casting the above molten steel into a slab;

[0044] 2. Hot rolling process: heating to 1242°C for rough rolling, final rolling temperature at 879°C, cooling to 701°C for coiling, hot rolling thickness is 6mm;

[0045] 3. Pickling process: pickling the hot-rolled coils above, the hydrochloric acid concentration of 1#, 2#, 3# acid tanks are 35~45 g / l, 50~80g / l, 100~130g / l, and the temperature is controlled separately At 80~85℃, 80~85℃, 80~85℃, the speed of pickling section is controlled at 100~240m / min, and then cold rolled into cold rolled thin strip steel, the cold rolling reduction rate is 70%;

[0046] 4. Bell-type annealing: the above cold-rolled thin strip steel is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com