Low-carbon cold-rolled steel plate for enamel and production method thereof

A technology of cold-rolled steel plate and production method, which is applied in the field of low-carbon cold-rolled steel plate for enamel and its production field, can solve problems such as scale explosion and poor adhesion, achieve optimal elongation, increase elongation, and maximize scale explosion resistance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

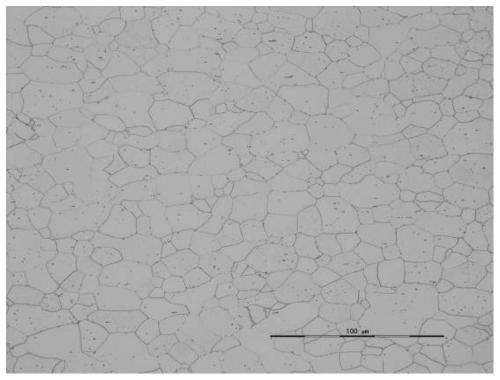

Image

Examples

Embodiment 1

[0051] A low-carbon cold-rolled steel sheet for enamelling according to the present invention. The mass percentages of the main chemical components of the cold-rolled steel sheet in this embodiment are: C=0.01%, Si=0.007%, Mn=0.30%, P=0.015%, S= 0.020%, Als=0.022%, Ti=0.039%, N=0.0064% (as shown in Table 1). In addition, the production method of a low-carbon cold-rolled steel plate for enamelling of the present invention, the specific process parameters in this embodiment are as follows (as shown in Table 2): the casting billet temperature is 1180°C; the final rolling temperature is 880°C; The temperature is 600°C; the reduction rate of cold rolling is 72.7%; the annealing is bell annealing: the heating rate of the heating section is 80°C / h, the temperature of the cold spot is 620°C, the heating time is 9h, and the rate of the cooling section is 30°C / h h, heat preservation at 360°C for 4 hours; the flat elongation rate is 0.8%. The properties of the steel plate produced accor...

Embodiment 2

[0054] A low-carbon cold-rolled steel sheet for enamelling according to the present invention. The mass percentages of the main chemical components of the cold-rolled steel sheet in this embodiment are: C=0.02%, Si=0.025%, Mn=0.10%, P=0.005%, S= 0.015%, Als=0.056%, Ti=0.011%, N=0.0027% (as shown in Table 1). In addition, the production method of a low-carbon cold-rolled steel plate for enamelling according to the present invention, the specific process parameters in this embodiment are as follows (as shown in Table 2): the casting billet exit temperature is 1220°C; the final rolling temperature is 910°C; The temperature is 650°C; the reduction rate of cold rolling is 79.4%; the annealing is bell annealing: the heating rate of the heating section is 50°C / h, the temperature of the cold spot is 630°C, the heating time is 5h, and the rate of the cooling section is 60°C / h h, heat preservation at 380°C for 3 hours; the flat elongation rate is 1.1%. The properties of the steel plate...

Embodiment 3

[0057] A low-carbon cold-rolled steel sheet for enamelling according to the present invention. The mass percentages of the main chemical components of the cold-rolled steel sheet in this embodiment are: C=0.03%, Si=0.020%, Mn=0.40%, P=0.009%, S= 0.030%, Als=0.037%, Ti=0.032%, N=0.0043% (as shown in Table 1). In addition, the production method of a low-carbon cold-rolled steel plate for enamelling according to the present invention, the specific process parameters in this embodiment are as follows (as shown in Table 2): the casting billet temperature is 1200°C; the final rolling temperature is 900°C; The temperature is 620°C; the reduction rate of cold rolling is 70.9%; the annealing is bell annealing: the heating rate of the heating section is 30°C / h, the temperature of the cold spot is 650°C, the heating time is 5h, and the rate of the cooling section is 80°C / h h, heat preservation at 400°C for 2 hours; the flat elongation rate is 1.4%. The properties of the steel plate prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com