Apparatus and method for detecting fish-scaling resistance of steel for enamel based on principle of micro-differential pressure

A detection device, micro-differential pressure technology, applied in the direction of material electrochemical variables, etc., can solve the problems of expensive liquid level detection device, affecting the accuracy of the grating sensor to capture the liquid level, etc., to achieve the effect of convenient and instant inspection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

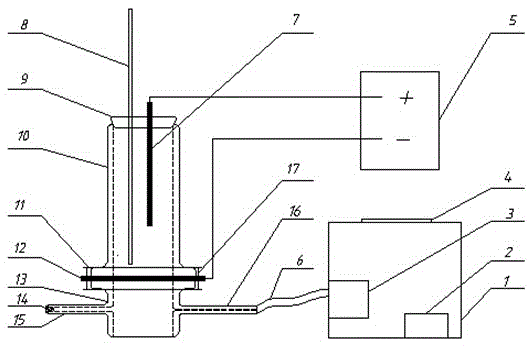

[0026] Such as figure 1 As shown in Fig. 1, a scale explosion resistance testing device for enamel steel based on the principle of differential pressure is composed of a testing part, a power supply part, an experimental part and a steel material sample to be tested.

[0027] The test part consists of a control cabinet 1, a computer 2, a differential pressure sensor 3, and a digital display touch screen 4, and the power supply is a DC constant current and constant voltage instrument 5. The experimental part consists of silicone tube 6, platinum electrode 7, thermometer 8, rubber plug 9, hydrogen evolution tank 10, epoxy resin plate fixing clip 11, hydrogen expansion tank 13, rubber plug 14, hydrogen diffusion liquid injection pipe 15, and hydrogen diffusion liquid outlet Pipe 16, fastening bolt 17 constitute.

[0028] The hole wall of the hydrogen exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com