Simple system for testing emission of motor vehicle through transient working condition method

A technology for transient working conditions and emission testing, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problem of not being able to truly reflect the driving situation of the vehicle, the inability to truly reflect the driving situation of the vehicle, and the low detection accuracy of the five-gas analyzer. and other issues, to achieve the effects of shortened test time, easy promotion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

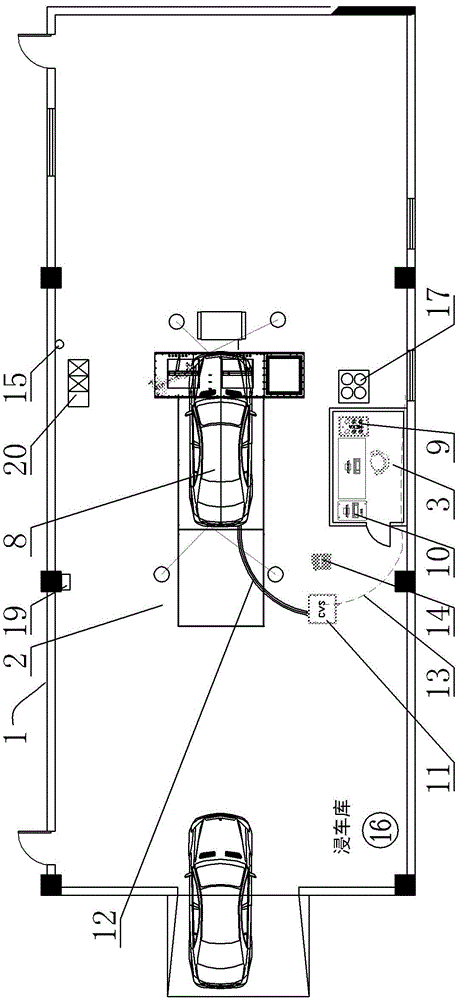

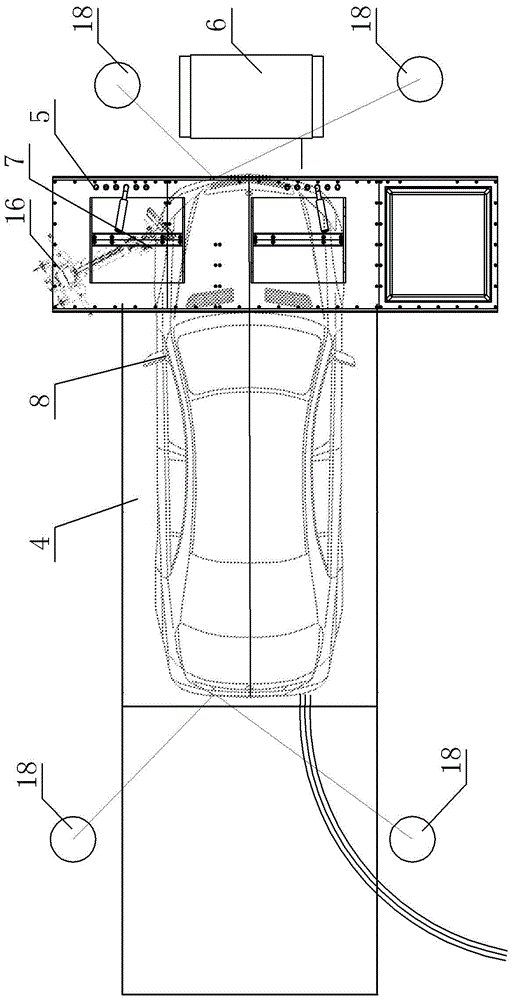

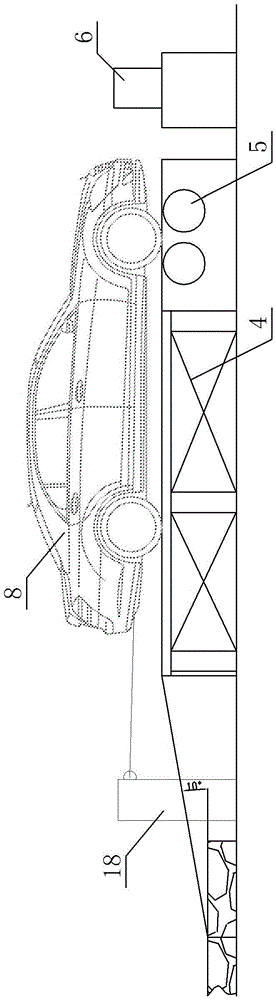

[0034]A simple emission test system for motor vehicle transient working conditions, characterized in that it includes a closed site 1, a test area 2 and a control area 3 are set in the site, the control area 3 can observe the test area 2, the test area 2 is provided with a test frame 4, a chassis dynamometer 5, a fan 6, and a monitoring camera 7. The front of the test frame 4 is provided with a chassis dynamometer 5, and the fan 6 is located at the front of the chassis dynamometer 5. position, the blower outlet of the fan 6 is arranged towards the front end of the vehicle to be tested 8, and the monitoring camera 7 is used to record the real-time picture of the vehicle to be tested 8; the control area 3 is provided with an emission analyzer 9, a main control computer 10 for the detection mechanism, and the test A constant-volume sampling unit 11 and a connecting pipe are arranged between the area 2 and the control area 3. The exhaust gas of the vehicle 8 to be tested is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com