Preparation method of low-sulfur small-particle-size nickel-cobalt-manganese hydroxide

A hydroxide, nickel-cobalt-manganese technology, used in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unfavorable industrial applications, and achieve easy to expand production, high flexibility, particle dispersion and spherical shape. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

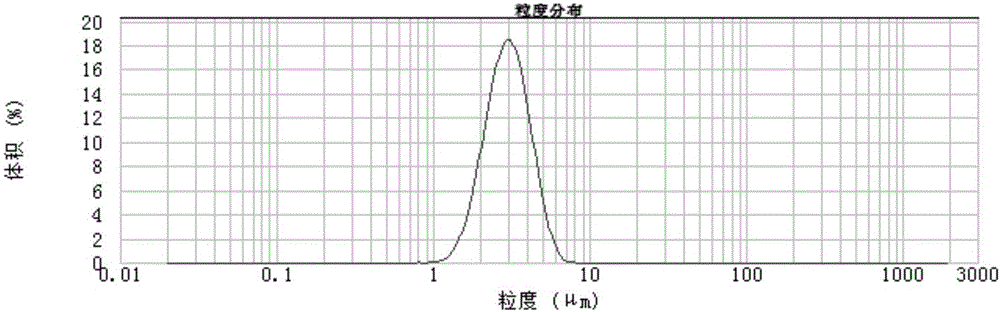

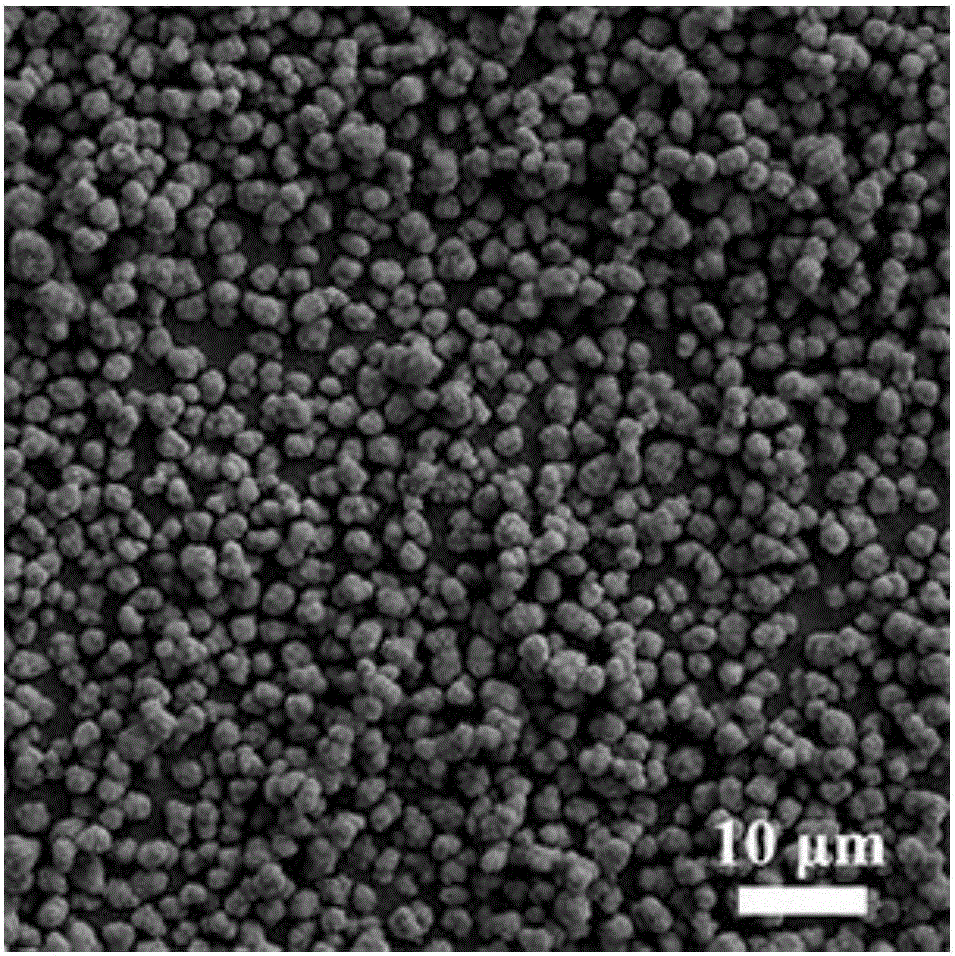

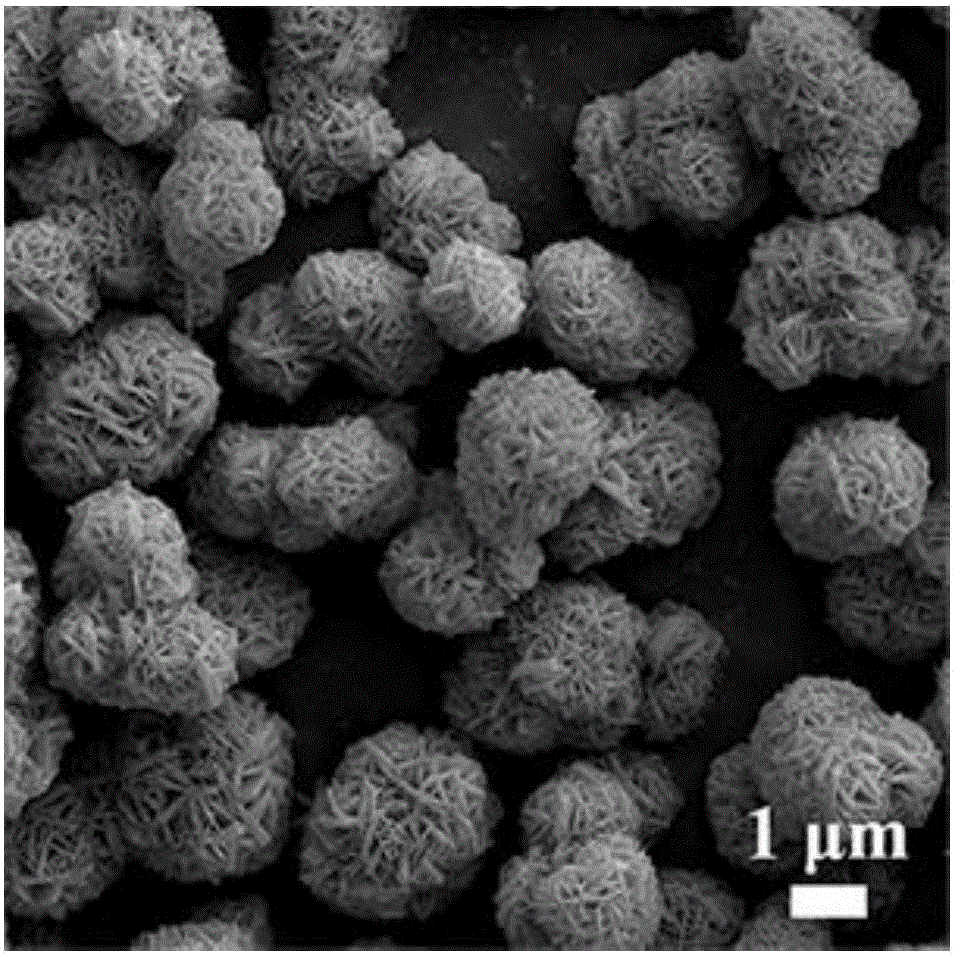

[0031] 1. Select nickel sulfate, cobalt sulfate and manganese sulfate, and prepare a mixed metal salt solution with a total metal ion concentration of 2.0mol / L according to the molar ratio of Ni:Co:Mn of 0.6:0.2:0.2; the prepared concentration is 6.0mol / L The sodium hydroxide solution is used as a precipitating agent; the ammonia solution with a concentration of 11.2mol / L is prepared as a complexing agent.

[0032] 2. Add 10L of bottom liquid to a 50L sealed reaction kettle with a stirring and temperature control device; the added bottom liquid is a solution with an ammonia concentration of 0.34mol / L, a pH value of 12.0, and a temperature of 50°C. Start stirring, and feed nitrogen into the reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process.

[0033] 3. Adjust the stirring speed of the reaction kettle to 700r / min, and use a precision metering pump to add the mixed metal salt solution, sodium hydroxide solution and ammonia solu...

Embodiment 2

[0038] 1. Select nickel sulfate, cobalt sulfate and manganese sulfate, according to the molar ratio of Ni:Co:Mn (1 / 3):(1 / 3):(1 / 3) to prepare a total metal ion concentration of 1.5mol / L Mix metal salt solution; prepare a sodium hydroxide solution with a concentration of 5.0mol / L as a precipitant; prepare an ammonia solution with a concentration of 10.6mol / L as a complexing agent.

[0039] 2. Add 200L of bottom liquid to a 1000L sealed reaction kettle with a stirring and temperature control device; the added bottom liquid is a solution with an ammonia concentration of 0.2mol / L, a pH value of 12.2, and a temperature of 45°C. Start stirring, and feed nitrogen into the reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process.

[0040] 3. Adjust the stirring speed of the reactor to 350r / min, and use a precision metering pump to add the mixed aqueous solution of nickel-cobalt-manganese soluble salts, sodium hydroxide solution and ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com