Preparation method of IN718 alloy spherical powder

A technology of IN718, spherical powder, applied in the field of preparation of INCONEL718 alloy spherical powder, can solve the problem that the demand of IN718 alloy powder cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

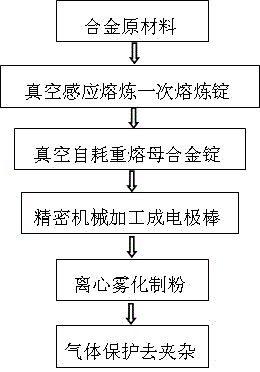

Image

Examples

Embodiment 1

[0027] A preparation method of IN718 alloy spherical powder, comprising the following steps:

[0028] Step 1, smelting of IN718 master alloy ingot;

[0029] 1) According to the main elements: 50wt% Ni, 17wt% Cr, 2.8wt% Mo, 4.75wt% Nb, 0.65wt% Ti, 0.20wt% Al, the balance is Fe; minor elements: 0.07 wt % C, 0.33 wt % Mn, 0.4 wt % Si, 0.014 wt % P, 0.014 wt % S, 0.9 wt % Co, 0.04 wt % Ta, 0.006 wt % B, 0.25 wt % Cu is used for alloy batching, and the raw material of Nb is NbFe with 70% Nb content; it is smelted in a vacuum induction melting furnace, and the vacuum degree is 5×10 -3 Fill the crucible of Pa vacuum induction melting furnace with half of Ni, Co, Mo, NbFe, Cr, Ti, Al, and the other half of Ni from bottom to top; Afterwards, In718 alloy primary smelting ingot was obtained;

[0030] 2) Remove the oxide skin on the surface of the primary smelting ingot, cut off the shrinkage cavity and process it into a consumable electrode, and carry out vacuum consumable remelting, ...

Embodiment 2

[0038] A preparation method of IN718 alloy spherical powder, comprising the following steps:

[0039] Step 1, smelting of IN718 master alloy ingot;

[0040] 1) According to the main elements: 53wt% Ni, 19wt% Cr, 3.0wt% Mo, 5.15wt% Nb, 0.9wt% Ti, 0.60wt% Al, the balance is Fe; minor elements: 0.05 wt% C, 0.25 wt% Mn, 0.3 wt% Si, 0.01 wt% P, 0.01 wt% S, 0.8 wt% Co, 0.03 wt% Ta, 0.005 wt% B, 0.2 wt% Cu is used for alloy batching, and the raw material of Nb is NbFe with 70% Nb content; it is smelted in a vacuum induction melting furnace at a vacuum degree of 2.5×10 -3 In the crucible of Pa vacuum induction melting furnace, fill half of Ni, Co, Mo, NbFe, Cr, Ti, Al, and the other half of Ni from bottom to top; Afterwards, In718 alloy primary smelting ingot was obtained;

[0041]2) Remove the oxide skin on the surface of the primary smelting ingot, cut off the shrinkage cavity and process it into a consumable electrode, and carry out vacuum consumable remelting, the vacuum degree...

Embodiment 3

[0049] A preparation method of IN718 alloy spherical powder, comprising the following steps:

[0050] Step 1, smelting of IN718 master alloy ingot;

[0051] 1) According to the main elements: 55wt% Ni, 21wt% Cr, 3.3wt% Mo, 5.50wt% Nb, 1.15wt% Ti, 0.8wt% Al, the balance is Fe; minor elements: 0.03 wt % C, 0.15 wt % Mn, 0.2 wt % Si, 0.008 wt % P, 0.008 wt % S, 0.06 wt % Co, 0.02 wt % Ta, 0.004 wt % B, 0.15 wt % Cu is used for alloy batching, and the raw material of Nb is NbFe with 70% Nb content; it is smelted in a vacuum induction melting furnace at a vacuum degree of 1.5×10 -3 Fill the crucible of Pa vacuum induction melting furnace with half of Ni, Co, Mo, NbFe, Cr, Ti, Al, and the other half of Ni from bottom to top; Afterwards, In718 alloy primary smelting ingot was obtained;

[0052] 2) Remove the oxide skin on the surface of the primary smelting ingot, cut off the shrinkage cavity and process it into a consumable electrode, and carry out vacuum consumable remelting, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com